Numerical control machining method for harmonic reducer flexible gear bi-directional crowned tooth profile

A technology of harmonic reducer and processing method, which is applied in the direction of gear teeth, components with teeth, metal processing equipment, etc. Deformation and other problems, to achieve the effect of high cost performance, ensure accuracy and efficiency, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

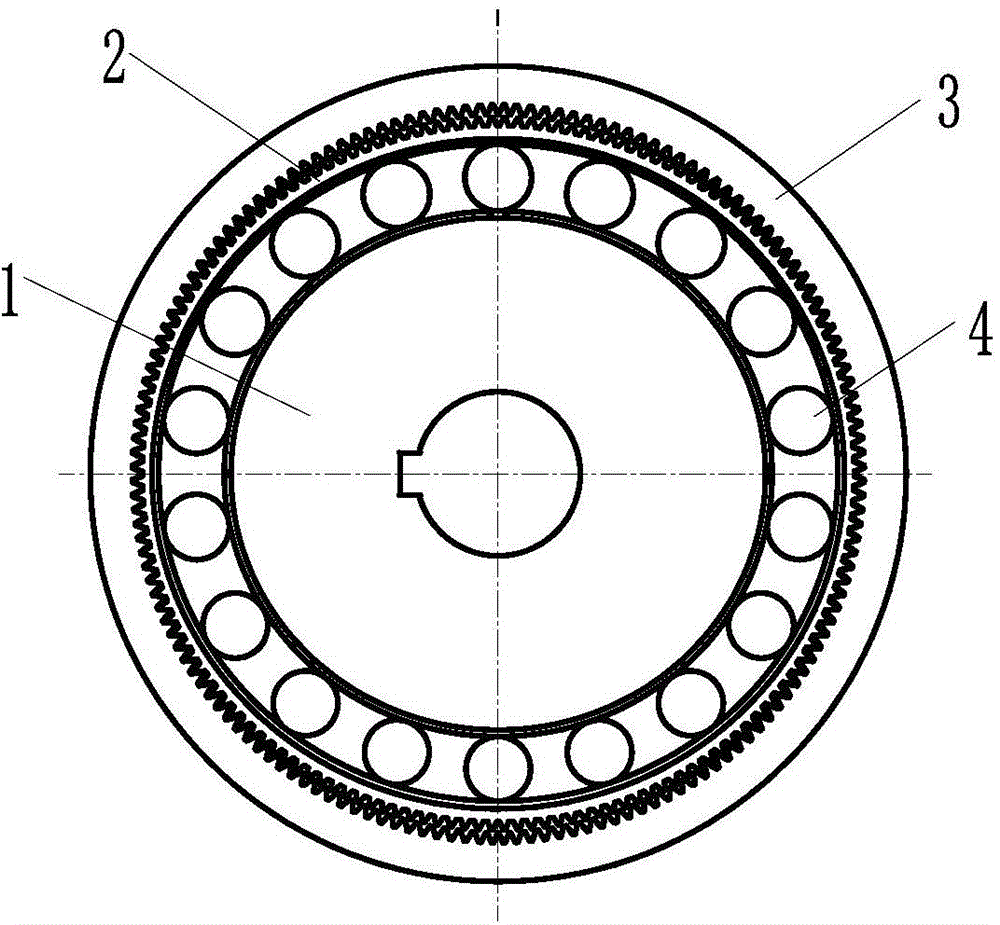

[0024] Combine below Figure 4~6 The embodiments of the present invention will be further described.

[0025] For a bidirectional drum-shaped stub flexspline harmonic gear, the flexspline processing includes the following steps:

[0026] (1) turning the flexible spline blank on a precision lathe to make the flexible spline semi-finished product 10;

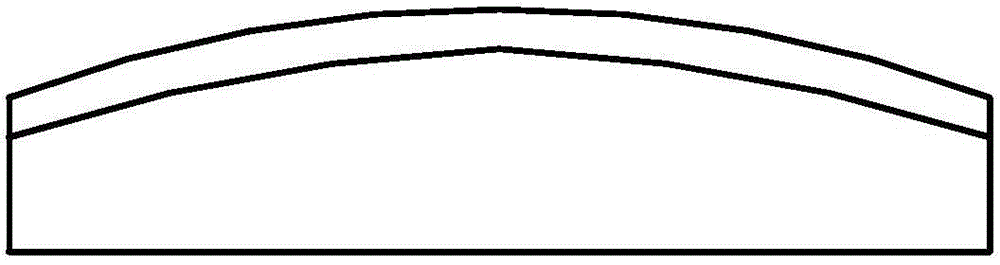

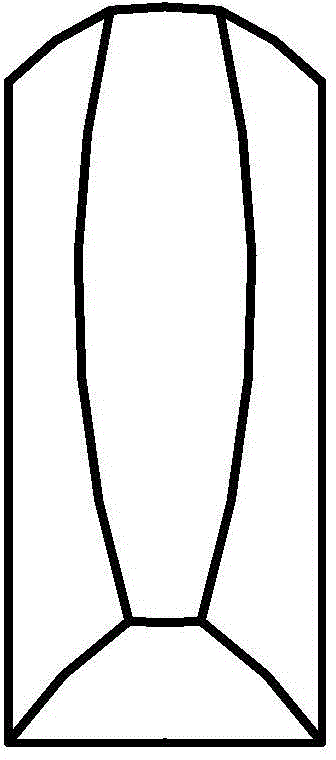

[0027] (2) Set the semi-finished flexspline 10 on the thin-walled sleeve 6, and fill the ring groove of the clamp body 5 with liquid plastic 7. When the rotating screw 9 pressurizes the cavity through the plunger 8, the liquid plastic 7 transmits pressure in all directions, and under the action of the pressure, the thin-walled sleeve 6 produces uniform elastic deformation in the radial direction, and is fixed by nuts 13 and gaskets 11 The bottom of the flexspline cup, and then the drum-shaped surface of the tooth top along the tooth direction is machined;

[0028] (3) A precision alignment instrument is used to precisely align ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com