Mechanical arm collision detection and response method based on six-dimensional force sensor

A technology of six-dimensional force sensor and collision detection, which is applied in manipulators, manufacturing tools, etc., can solve problems such as product damage, insufficient sensitivity to ensure the safety of the operated product, and damage, and achieve fast response, reasonable and practical methods, and detection high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method for detecting and responding to the collision of the robotic arm of the present invention will be further described below in conjunction with the accompanying drawings. This description is only exemplary and is not intended to limit the protection scope of the present invention.

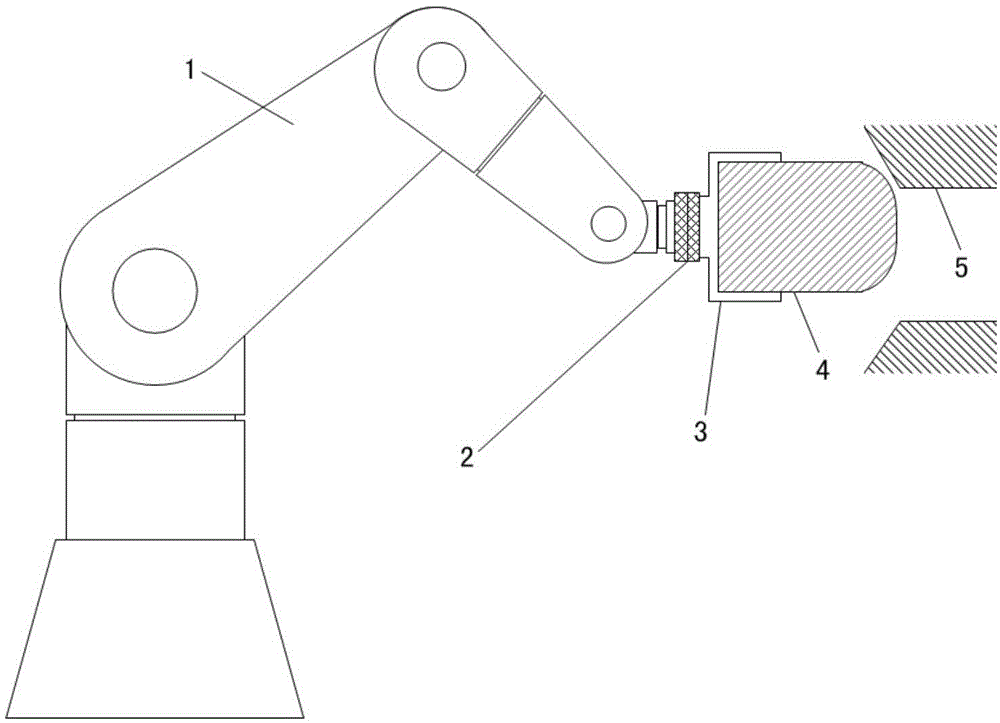

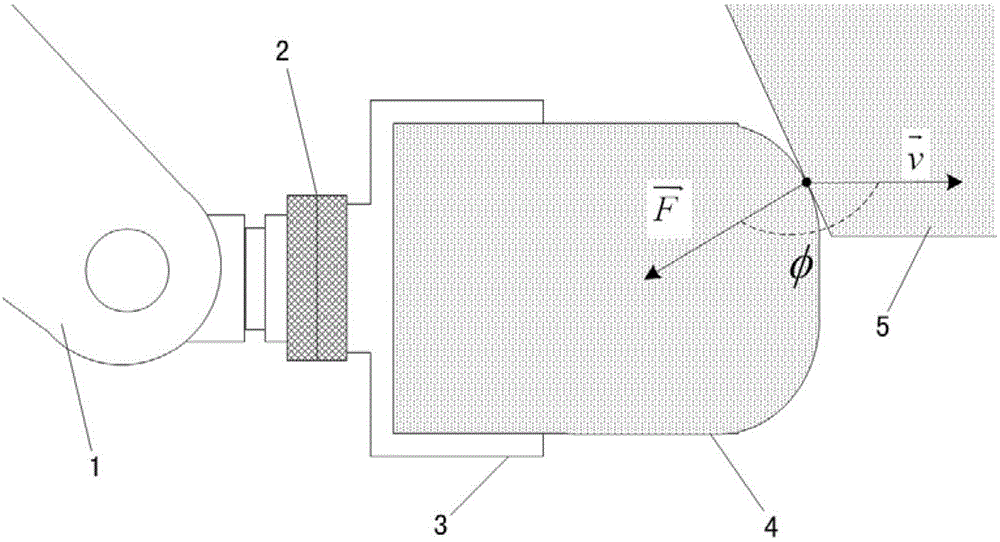

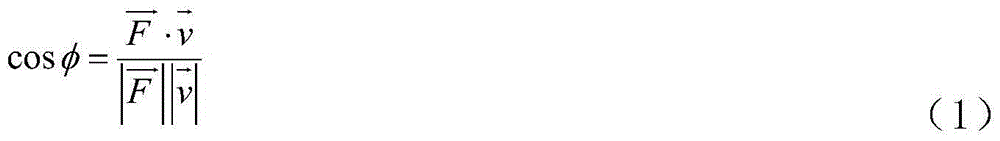

[0025] Such as figure 1 As shown, the six-dimensional force sensor 2 is installed between the end of the mechanical arm 1 and the clamp 3, the workpiece 4 is clamped by the clamp 3, and the mechanical arm 1 transports the workpiece 4 to the Assembly chamber 5. In the above technical solution, the six-dimensional force sensor is a mature sensor product well known to those in the industry, which is easy to purchase (such as the six-dimensional force sensor of ATI Company), and the data obtained by each measurement has six components, including Force components in the directions of the three coordinate axes in the six-dimensional force sensor's own coordinate system, and torque compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com