Automatic production line for foam cement wallboard

An automatic production line and foamed cement technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of high labor intensity, a lot of manpower, and many molds, and achieve stable solidification and condensation quality and save manpower. use and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

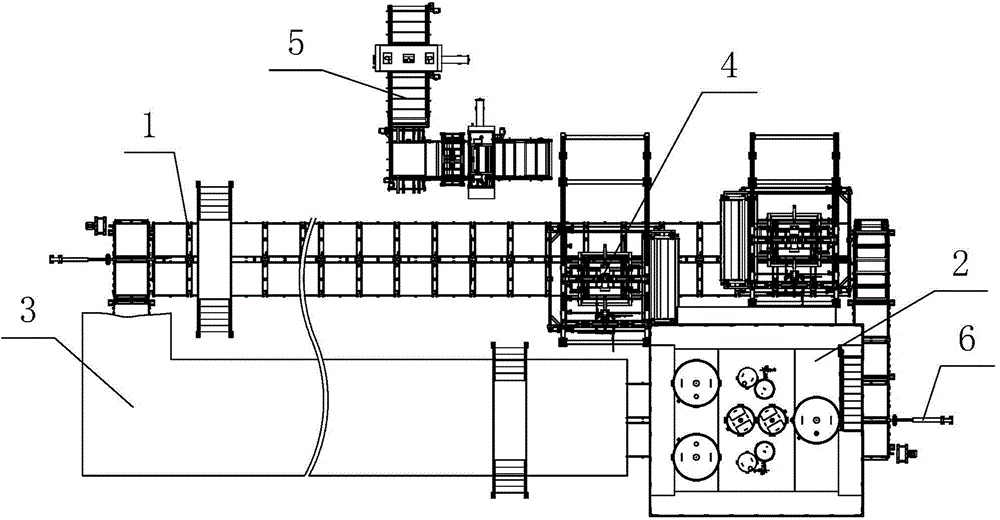

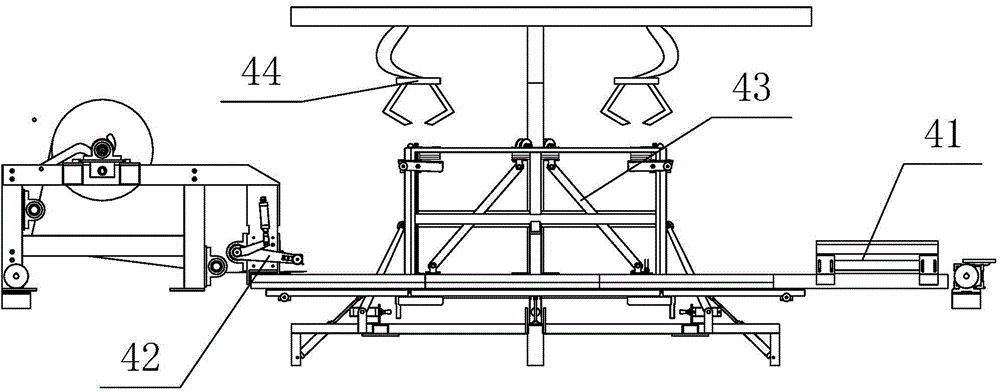

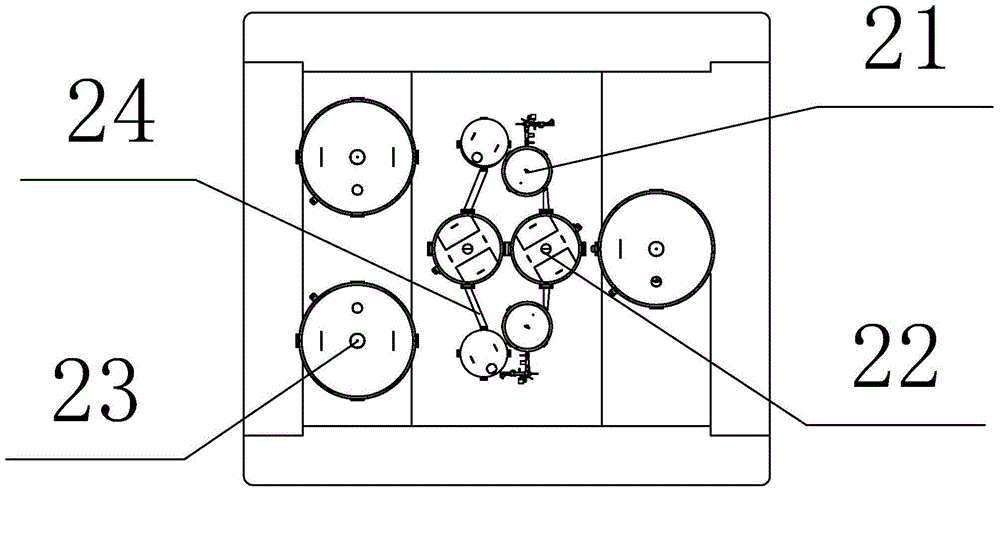

[0016] Example: such as figure 1 , figure 2 and image 3 As shown, the present invention includes a circulating conveyor chain plate 1, which is provided with a stirring and pouring system 2, a constant temperature and humidity curing tunnel 3, and a cutting and filming device 4 in sequence from the beginning to the end of the conveyor chain plate 1, and also includes sawing System 5, the sawing system 5 is located on the outside of the conveying chain plate 1, and is close to the blanking and film-laying device 4; the stirring and pouring system 2 includes a raw material storage tank 21, a stirring tank 22 and a pouring tank 23, and the raw material storage The tank 21 and the mixing tank 22 are connected by a fiber metering and conveying system 24; the constant temperature and humidity curing tunnel 3 is cylindrical in shape with both ends open, and the transport chain plate passes through the constant temperature and humidity curing tunnel 3 However, there are two convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com