Novel light structural material, and preparation method and application thereof

A structural material and lightweight technology, applied in the direction of upper structure, upper structure sub-assembly, chemical instruments and methods, etc., can solve the problems of easy wear, poor corrosion resistance, poor noise reduction and fire prevention effects, etc., and achieve improved strength , increase toughness, enhance the effect of heat insulation and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

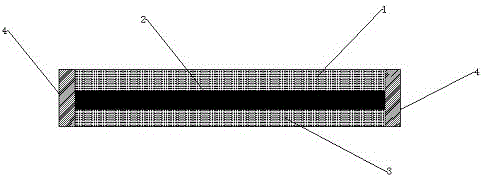

[0042] A new type of lightweight structural material, comprising a three-layer structure of two layers of carbon fiber reinforced layers and an intermediate layer, the intermediate layer is located in the middle of the two layers of carbon fiber reinforced layers, and the side edges of the three-layer structure include 10mm polyester staple fibers For the reinforcement layer, the middle layer includes 40% jute fiber by weight, 25% polypropylene fiber, 15% polyester fiber, 10% glass fiber and 10% volcanic ash.

[0043] The preparation method of the novel lightweight structural material comprises the following steps:

[0044] (1) Preparation of the middle layer: uniformly mix the above-mentioned raw materials of the middle layer to make a mixture; heat the above-mentioned mixture to a plasticized state at a temperature of 200° C. for 150 seconds, and make the middle layer by compression molding;

[0045] (2) Lay the middle layer between two layers of carbon fiber reinforced laye...

Embodiment 2

[0049] A new type of lightweight structural material, comprising a three-layer structure of two fiber-reinforced layers and a middle layer, the middle layer is located in the middle of the two fiber-reinforced layers, and the side edges of the three-layer structure include 20mm polyester staple fibers Reinforcing layer, described middle layer comprises the jute fiber of 35% by weight, the polypropylene fiber of 30%, the polyester fiber of 25%, 5% glass fiber, the volcanic ash of 5%; Described fiber reinforcing layer contains glass fiber and synthetic resin fibers.

[0050] The preparation method of the novel lightweight structural material comprises the following steps:

[0051] (1) Preparation of the middle layer: uniformly mix the above-mentioned raw materials of the middle layer to make a mixture; heat the above-mentioned mixture to a plasticized state at a temperature of 170° C. for 50 seconds, and make the middle layer by compression molding;

[0052] (2) The middle laye...

Embodiment 3

[0056] A new type of lightweight structural material, including a three-layer structure of two layers of glass fiber reinforced layers and an intermediate layer, the intermediate layer is located in the middle of the two layers of fiber reinforced layers, and the side edges of the three-layer structure include 20mm polypropylene short The fiber reinforced layer, the middle layer comprising 30% jute fibers by weight, 30% polypropylene fibers, 24% polyester fibers, 8% glass fibers, and 8% volcanic ash;

[0057] The preparation method of the novel lightweight structural material comprises the following steps:

[0058](1) Preparation of the middle layer: uniformly mix the above-mentioned raw materials of the middle layer to make a mixture; heat the above-mentioned mixture to a plasticized state at a temperature of 250° C. for 200 seconds, and make the middle layer by compression molding;

[0059] (2) The intermediate layer is laid between two layers of glass fiber reinforced layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com