Device based on patterns printed on surface of timber

A wood surface and pattern technology, applied in printing, stamping and other directions, can solve the problems of easily damaged wood surface, poor engraving quality, shortened service life, etc., and achieve the effect of high molding quality, guaranteed service life and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

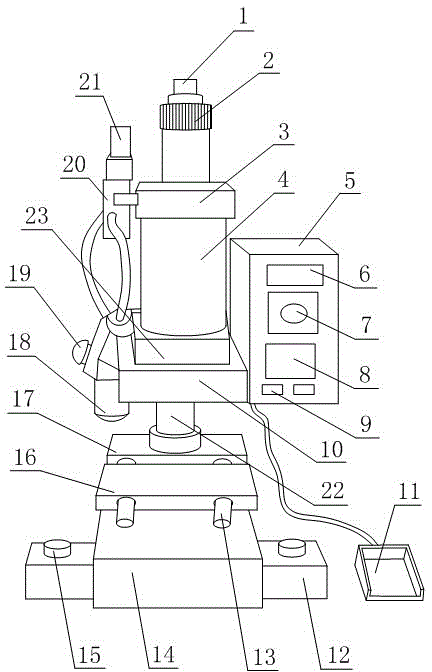

[0013] Such as figure 1 As shown, the device based on printing patterns on the wood surface includes a base 14, a positioning bolt 1 is arranged above the base 14, the bottom end of the positioning bolt 1 is vertically fixed to the top of the base 14, and a heating plate 17 is arranged on the base 14. The heating plate 17 is provided with a forming die 16, the bottom of the forming die 16 is arranged below the heating plate 17, the mounting plate 10 is arranged above the heating plate 17, the cylinder 4 is arranged above the mounting plate 10, and the cylinder 4 is fixed with the positioning bolt 1. A piston rod 22 is arranged between the cylinder 4 and the heating plate 17. One end of the piston rod 22 is connected to the inside of the cylinder 4, and the other end passes through the mounting plate 10 and is connected to the heating plate 17. The piston rod 22 can carry out lead along the inner wall of the cylinder 4. Vertically moving, a control box 5 is arranged outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com