Sludge-water separate discharging method for strengthening stable operation of aerobic granular sludge process

An aerobic granular sludge, stable operation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. Poor, unstable system operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

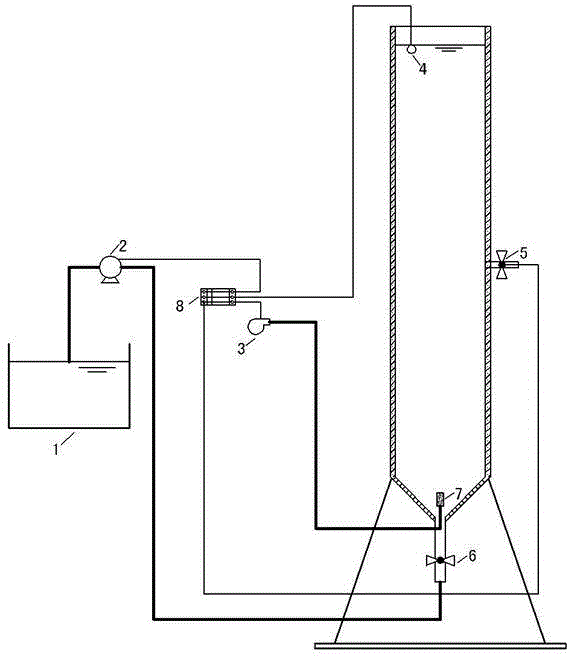

[0021] Such as figure 1 As stated, the main body of the reactor is a cylindrical aerobic granular sludge reactor with a H / D (height-to-diameter ratio) of 8. The reactor is arranged in order from bottom to top: water inlet 6, aeration device 7, water outlet 5, liquid level gauge 4. The water inlet 6 at the bottom of the reactor is connected with the water inlet pump 2 through the water inlet pipe, and the water is fed from the water distribution tank 1, and the upper liquid level of the water inlet is controlled by the liquid level gauge 4. The air is input to the aeration device 7 through the air blower 3, and the water is discharged from the reactor through the water outlet 5 in the middle. All water intake, aeration, and drainage in the device are automatically controlled by the programmable controller 8 . Of course, the reactor can be modified in many ways, which are well known to those skilled in the art.

[0022] Inoculate the activated sludge in the SBR reactor of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com