Low-beating degree ultrafine centrifugal glass wool drawing device and drawing method

A technology of centrifugal glass wool and percussion degree, used in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high percussion degree, insufficient flexibility, low percussion degree, etc., achieve excellent sound absorption and heat insulation performance, small diameter, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

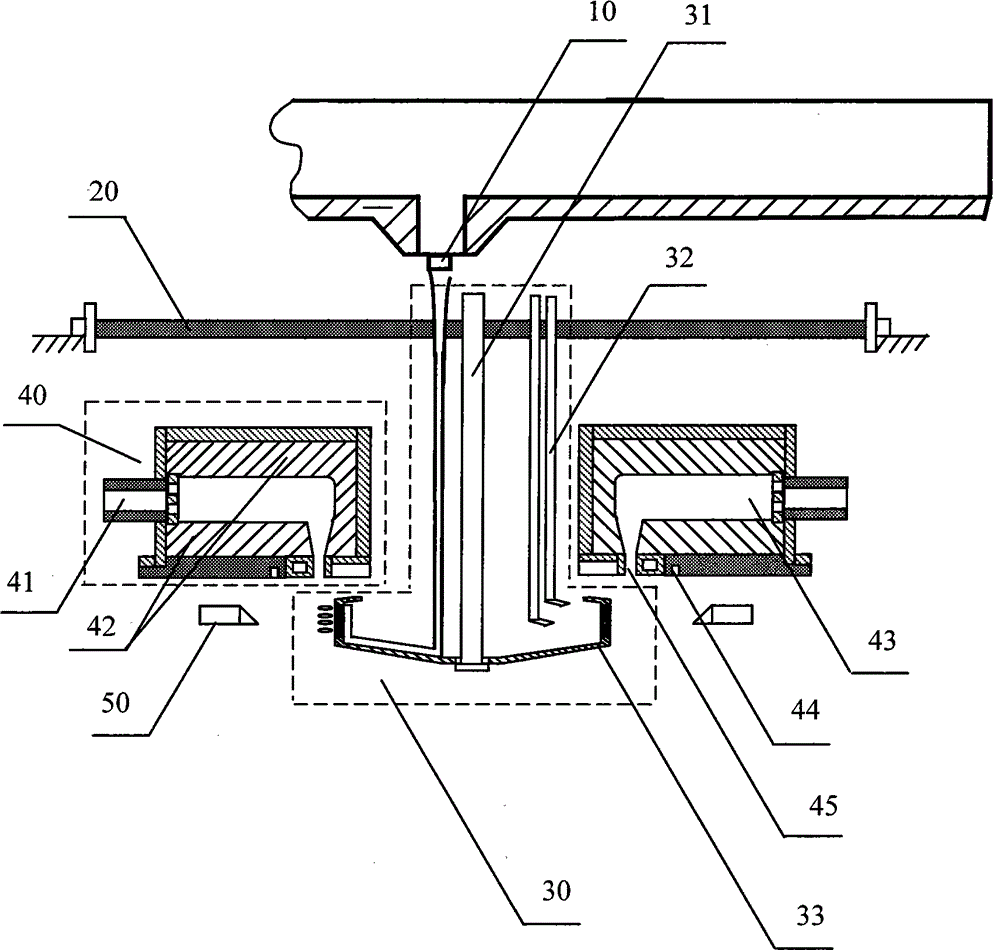

[0029] Such as figure 1 Low percussion ultrafine centrifugal glass wool drawing device shown. The distance between the high temperature air stretching port and the centrifugal disc is 5mm, the gap width of the high temperature air stretching port is 8mm, and the distance between the cold air stretching port and the high temperature air stretching port is 8mm. Low percussion ultrafine centrifugal glass wool drawing method:

[0030] (1) Start the rotating spindle to make the centrifugal disc with a diameter of 250 mm, 8600 holes in the side wall, and a diameter of 0.7 mm in the side wall rotate at a high speed at a speed of 2600 rad / min;

[0031] (2) Turn on two flame heating internal combustion burners that heat the centrifugal disc at an angle of 60°, and heat the centrifugal disc to 900°C;

[0032] (3) The mixing ratio of natural gas and air into the gas inlet is 1:11

[0033] (4) Air is fed into the cold air stretching port and the air cutter, the temperature of the cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com