Open-celled polypropylene microcellular foaming sheet and production method thereof

A technology of microcellular foaming and polypropylene, which is applied in the field of open-cell polypropylene microcellular foam sheet and its production, can solve the problems such as processing difficulties of open-cell polypropylene microcellular foam sheet, and achieve saturation The effect of short time, easy control and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

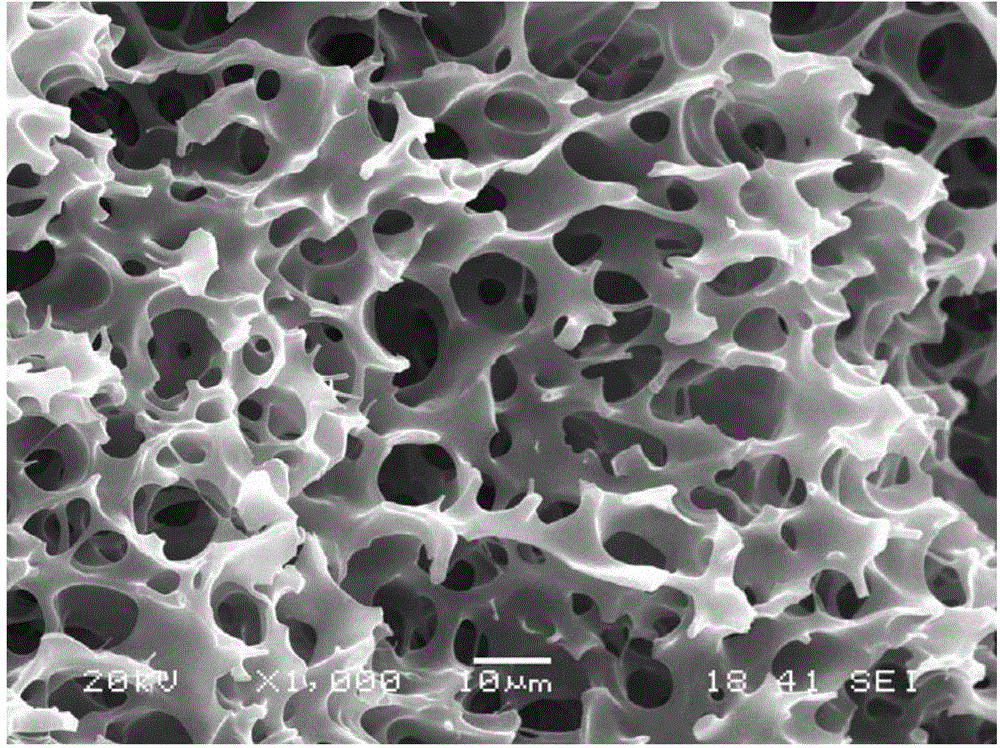

[0032] Such as figure 1 As shown, a kind of open-cell polypropylene microporous foam sheet comprises the following components: 100 parts by weight of polypropylene resin, 60 parts by weight of polyethylene resin, wherein: the molecular weight distribution value of the polypropylene resin is 16 isotactic polypropylene, the polyethylene resin adopts low-density polyethylene with a molecular weight distribution value of 5.

[0033] The production method adopted by the above-mentioned a kind of open-cell polypropylene microporous foam sheet comprises the following steps:

[0034] a) Mixing of raw materials: the polypropylene resin and polyethylene resin are sucked into the mixer in proportion, and after being fully mixed, sucked into the hopper of the extruder and dried, the drying temperature is 80°C;

[0035] b) Plasticizing and mixing: plasticize and mix the dried raw material mixture in step a) through a twin-screw extruder to form a double continuous phase structure. The tem...

Embodiment 2

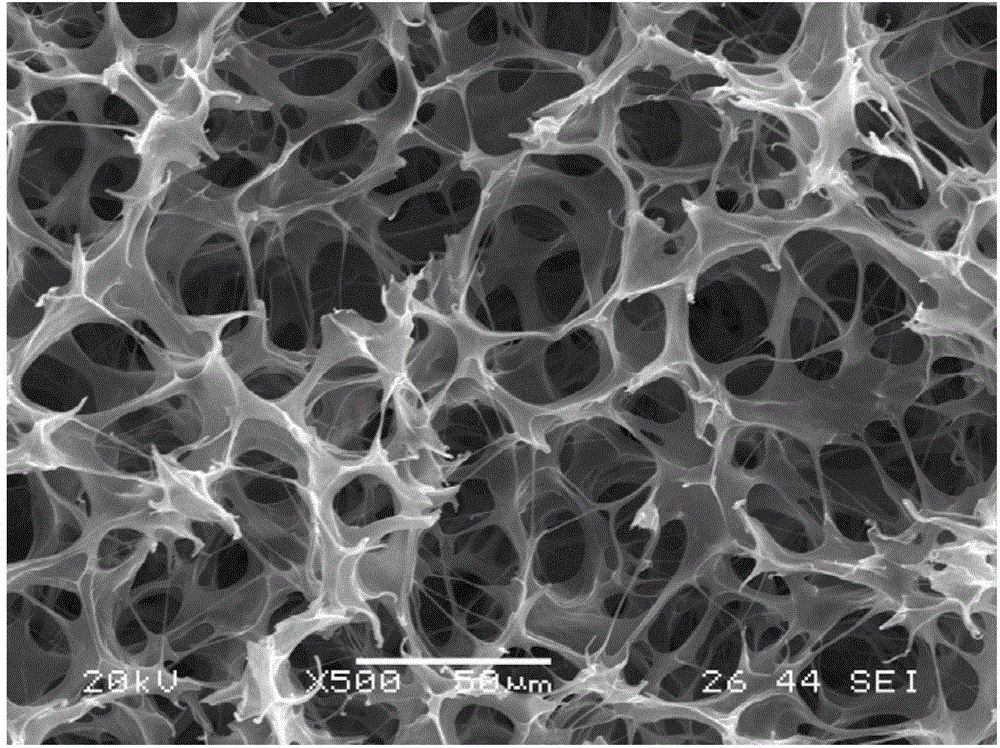

[0043] Such as figure 2 As shown, a kind of open-cell polypropylene microporous foam sheet comprises the following components: 100 parts by weight of polypropylene resin, 80 parts by weight of polyethylene resin, wherein the polypropylene resin adopts a molecular weight distribution value of 19 random copolymerized polypropylene, the polyethylene resin adopts high-density polyethylene with a molecular weight distribution value of 7.

[0044] The production method adopted by the above-mentioned a kind of open-cell polypropylene microporous foam sheet comprises the following steps:

[0045] a) Mixing of raw materials: the polypropylene resin and polyethylene resin are sucked into the mixer in proportion, and after being fully mixed, sucked into the hopper of the extruder and dried, the drying temperature is 80°C;

[0046] b) Plasticizing and mixing: Plasticize and mix the dried raw material mixture in step a) through a twin-screw extruder to form a double continuous phase stru...

Embodiment 3

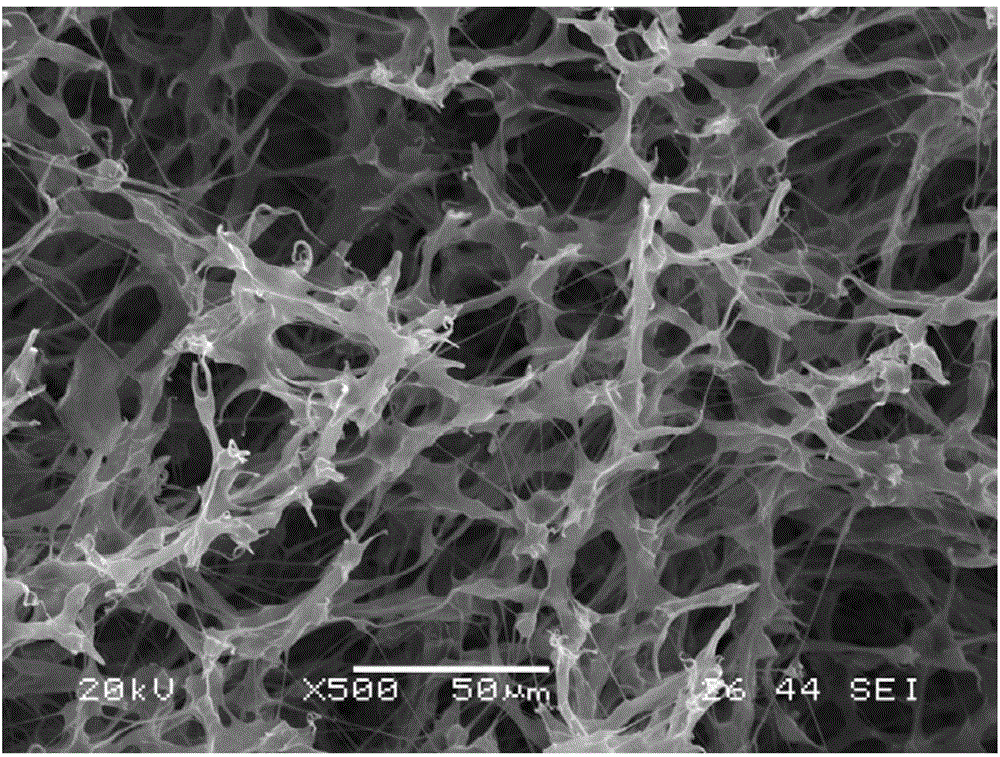

[0054] Such as image 3 As shown, a kind of open-cell polypropylene microporous foam sheet comprises the following components: 100 parts by weight of polypropylene resin, 100 parts of polyethylene resin, wherein: polypropylene resin adopts a high molecular weight distribution value of 21 Melt strength polypropylene, polyethylene resin with a molecular weight distribution value of 11 linear low density polyethylene.

[0055] The production method adopted by the above-mentioned a kind of open-cell polypropylene microporous foam sheet comprises the following steps:

[0056] a) Mixing of raw materials: the polypropylene resin and polyethylene resin are sucked into the mixer in proportion, and after being fully mixed, sucked into the hopper of the extruder and dried, the drying temperature is 80°C;

[0057] b) Plasticizing and mixing: Plasticize and mix the dried raw material mixture in step a) through a twin-screw extruder to form a double continuous phase structure. The temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com