Controllable-humidity vapor-heating/humidifying leather-lapping cloth bonding processing apparatus

A processing equipment and steam technology, applied in leather softening, leather manufacturing, small raw hide/big raw hide/leather/fur treatment, etc., can solve the problems of leather fabric color difference, easy peeling, insufficient adhesion of interlining, etc., and achieve easy operation , Simple equipment structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

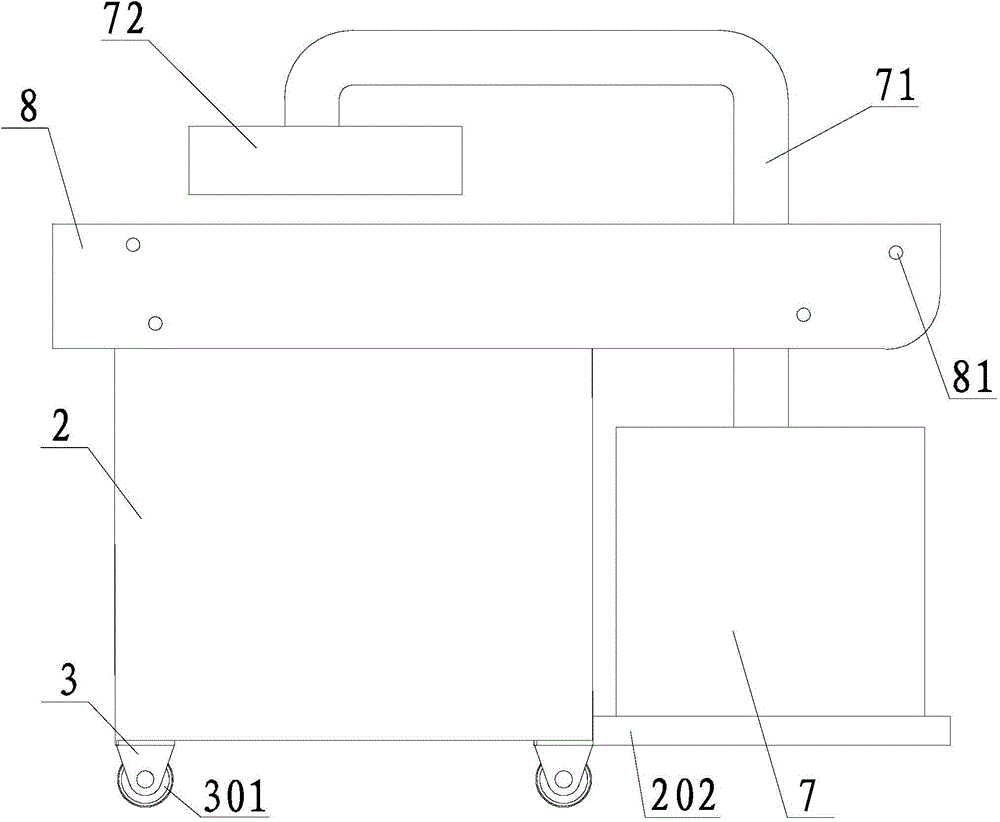

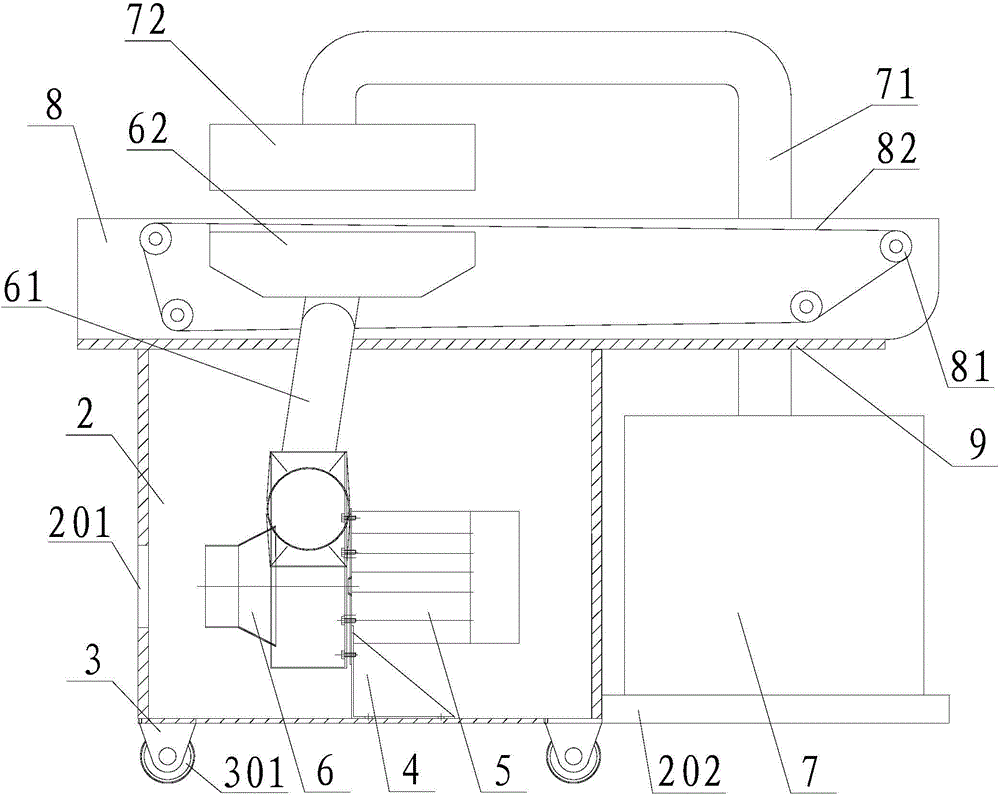

[0017] refer to figure 1 and figure 2 , a humidity controllable steam heating and humidifying leather and interlining bonding processing equipment of the present invention, comprising a dehumidification box 2, a wheel bracket 3, a motor fixing bracket 4, a motor 5, a fan 6, a steam generator 7, a working side plate 8 and Working plate 9, the bottom of the dehumidification box 2 is equipped with a motor fixing bracket 4 through bolts, and a motor 5 is installed on the motor fixing bracket 4, and the motor 5 is fixedly connected with the fan 6, and the fan 6 is installed with water vapor Absorption and transmission pipe 61, the end of the water vapor absorption and transmission pipe 61 is connected with a steam absorption plate 62, the upper part of the dehumidification box 2 is provided with a working plate 9, and the working plate 9 is provided with a working side plate 8, and the working side plate 8 A drive roller 81 is installed on the drive roller 81, and a conveyor belt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com