Improved galvanized wire grate closed box body bypass system mounting method

A technology of closed box and bypass system, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of shortening the construction period, unreasonable grate structure, labor and materials, etc. Achieve the effect of reducing project cost, improving economic benefit and guaranteeing construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

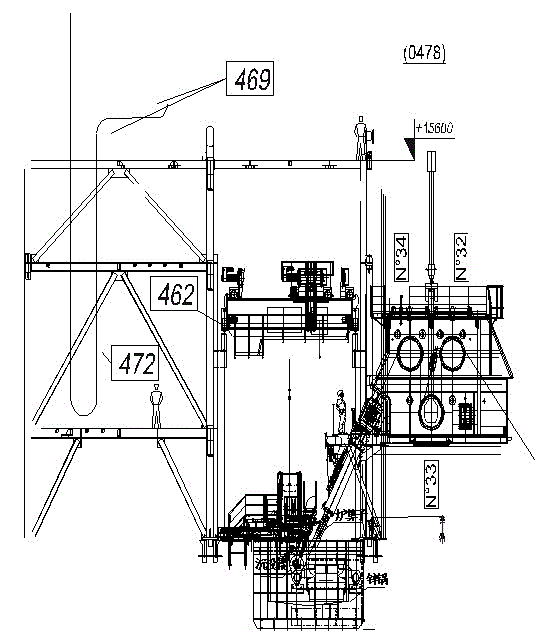

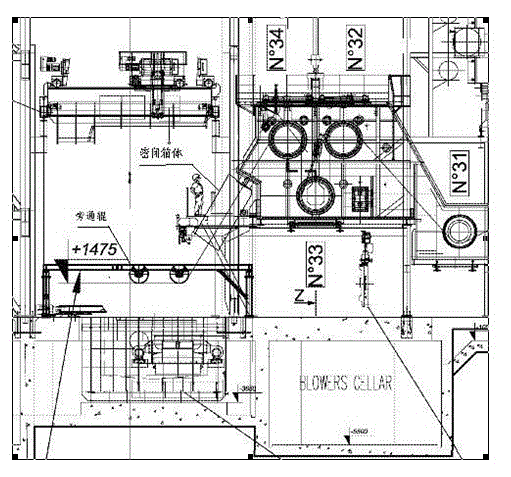

[0036] see now figure 2 , figure 2 It is a schematic diagram of the bypass system of the closed box of the galvanizing line furnace grate according to the embodiment of the present invention. The improved galvanizing line furnace grate airtight box bypass system installation method of the present invention comprises an improved airtight box and a bypass roller, and is characterized in that it comprises the following steps:

[0037] a. Make a closed box to replace the grate

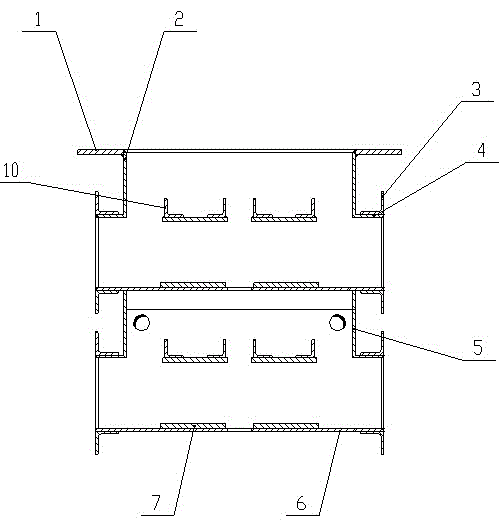

[0038] image 3 It is a schematic diagram of the structure of the sealed box of the embodiment of the present invention. The airtight box is set up as upper and lower parts, the first part is the lower italic connection nipple, and the second part is the airtight box. The purpose of this is to be divided into two parts, small in size and easy to install in such a small space.

[0039] b. Install the airtight box, including the following steps:

[0040] (1) Connect the lower italic body with the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap