Small-radius curve concrete sleeper component

A small-radius curve and concrete technology, which is applied in the direction of rails, rails, movable rails, etc., can solve the problems of decreased driving safety factor, increased maintenance costs, and lateral displacement of rails, etc., and achieves improved safety factor, convenient construction and replacement, and saving rail effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

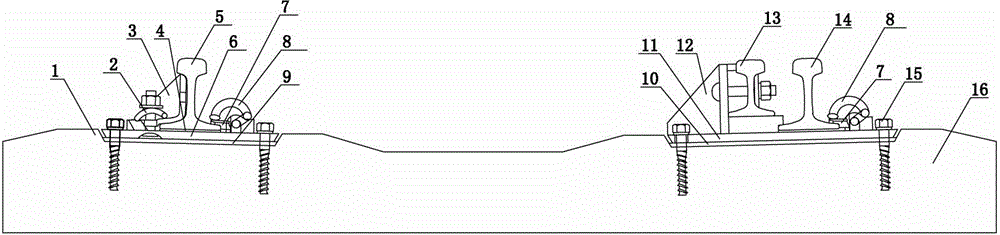

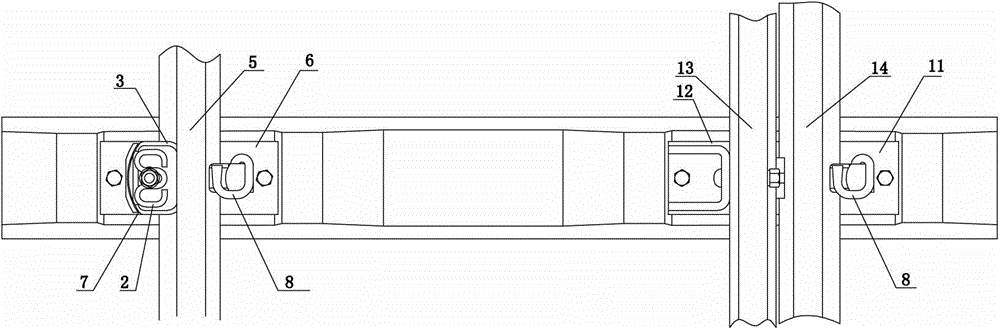

[0020] like figure 1 , 2 As shown, the small-radius curved concrete sleeper assembly of the present invention includes a small-radius curved sleeper 16, the upper strand steel rail 5 and the lower strand steel rail 14 arranged on the small-radius curved sleeper 16, and the protective rails arranged outside the lower strand steel rail. Rail, characterized in that the top surface of the small-radius curved sleeper 16 is provided with two backing plate grooves with shoulders 1,

[0021] The outer side of the upper stock rail 5 is provided with an upper stock rail brace 3, and the bottom of the upper stock rail 5 is provided with an upper stock backing plate 6, and the bottom of this upper stock backing plate 6 is provided with an upper stock buffer rubber pad 9, and There is also an upper rail bottom rubber pad 4 between the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com