Composite carrier SCR denitration catalyst and preparation method thereof

A technology of denitration catalyst and composite carrier, which is applied in the field of composite carrier SCR denitration catalyst and its preparation, can solve the problems of inability to meet the denitration requirements of industrial furnaces and kilns, high content of poisoning elements, and high ash content, and achieves increased specific surface area, adsorption and adsorption. The effect of enhanced capacity and high denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

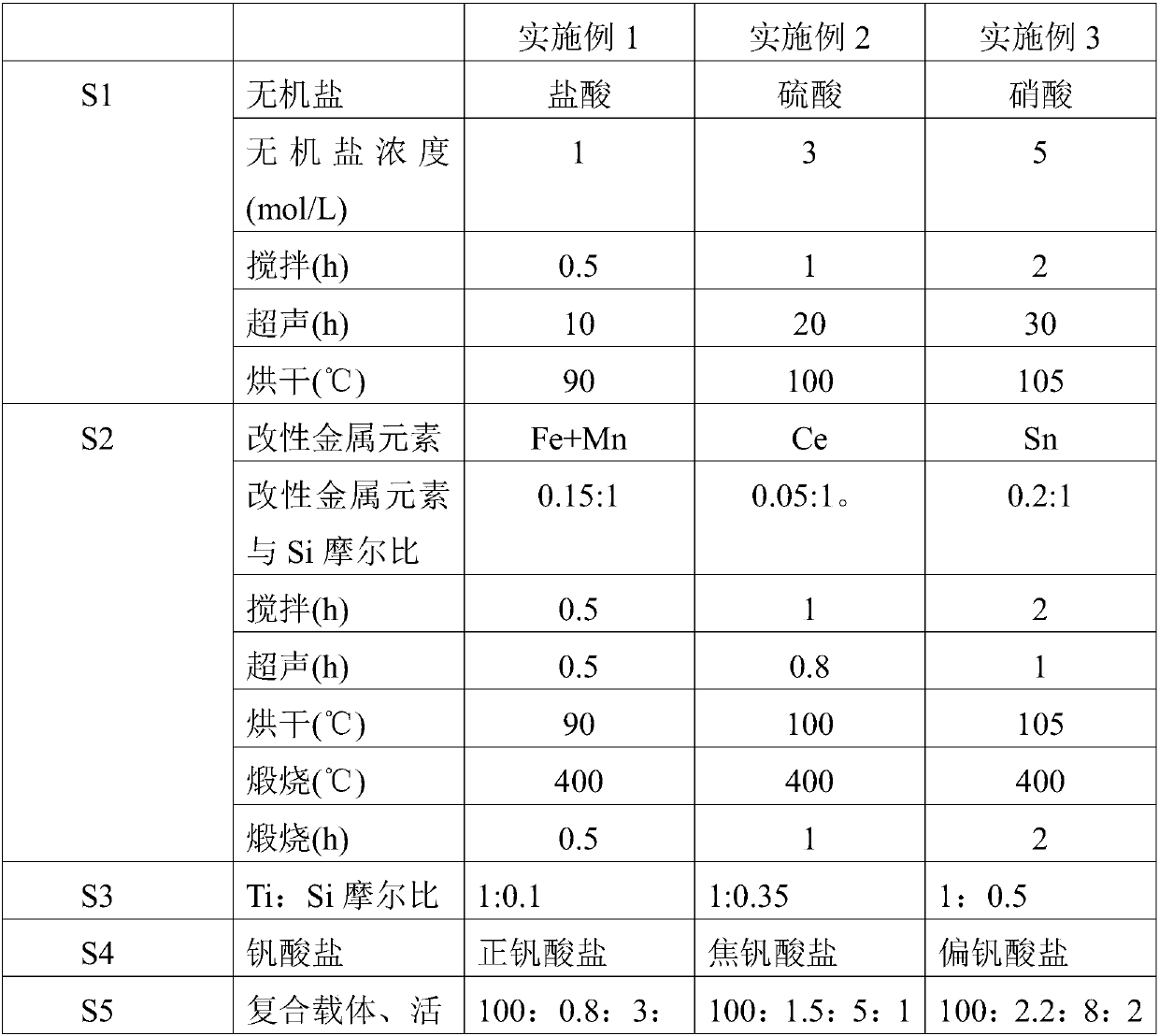

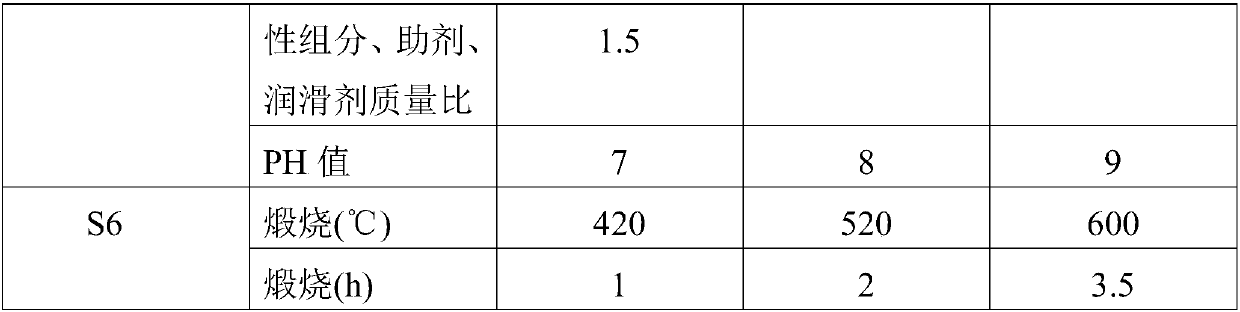

Embodiment 1

[0052] Sample performance: specific surface area 115m 2 / g, abrasion resistance 47mg / 100U.

[0053] Catalyst denitration performance test: the reaction temperature is 160℃~420℃, and the flue gas components are NO (500ppm), NH 3 (500ppm), O 2 (5%), carrier gas is N 2 , the airspeed is 10000h -1 , in this reaction temperature range, the catalyst denitration efficiency is stable above 93%, N 2 The selectivity is greater than 95%.

[0054] Catalyst sulfur and water resistance performance test: On the basis of the denitration performance test conditions, 1000ppm SO2 and 10% water vapor were continuously fed for 24 hours, and other test conditions remained unchanged. Within this reaction temperature range, the catalyst denitration efficiency was stable at more than 91%, N 2 The selectivity is greater than 90%.

[0055] Catalyst resistance to alkaline earth metal poisoning performance test: 500 μmol / g of Ca was loaded on the catalyst by impregnation method 2+ , calcined at 400...

Embodiment 2

[0057] Sample performance: specific surface area 128m 2 / g, abrasion resistance 39mg / 100U.

[0058] Catalyst denitration performance test: the reaction temperature is 160℃~420℃, and the flue gas components are NO (500ppm), NH 3 (500ppm), O 2 (5%), carrier gas is N 2 , the airspeed is 10000h -1 , in this reaction temperature range, the catalyst denitration efficiency is stable above 96%, N 2 The selectivity is greater than 95%.

[0059] Catalyst sulfur resistance and water resistance performance test: On the basis of the denitration performance test conditions, 1000ppm SO2 and 10% steam were continuously fed for 24 hours, and other test conditions remained unchanged. Within this reaction temperature range, the catalyst denitration efficiency was stable at more than 92%, N 2 The selectivity is greater than 91%.

[0060] Catalyst resistance to alkaline earth metal poisoning performance test: 800 μmol / g K was loaded on the catalyst by impregnation method + , calcined at 400 °...

Embodiment 3

[0062] Sample performance: specific surface area 109m 2 / g, abrasion resistance 28mg / 100U.

[0063] Catalyst denitration performance test: the reaction temperature is 160℃~420℃, and the flue gas components are NO (500ppm), NH 3 (500ppm), O 2 (5%), carrier gas is N 2 , the airspeed is 10000h -1 , in this reaction temperature range, the catalyst denitration efficiency is stable above 97%, N 2 The selectivity is greater than 95%.

[0064] Catalyst sulfur resistance and water resistance performance test: On the basis of the denitration performance test conditions, 1000ppm SO2 and 10% water vapor were continuously fed for 24 hours, and other test conditions remained unchanged. Within this reaction temperature range, the catalyst denitration efficiency was stable above 90%, N 2 The selectivity is greater than 95%.

[0065] Catalyst resistance to alkaline earth metal poisoning performance test: 1000 μmol / g Na was loaded on the catalyst by impregnation method + , calcined at 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com