A caving mining method induced by liquid carbon dioxide blasting

A liquid carbon dioxide, caving mining technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of large dynamic damage, limited application of natural caving method, difficult continuous and effective rock caving, etc. Effects of damage, controllable blasting energy, and reduced mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

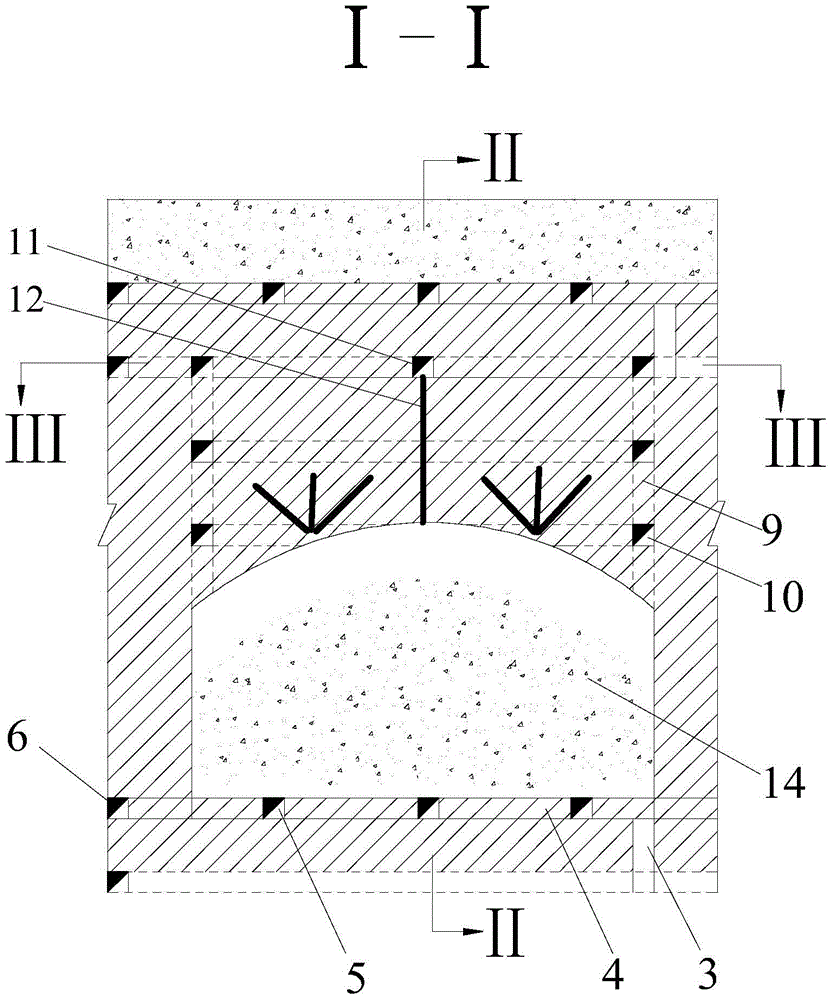

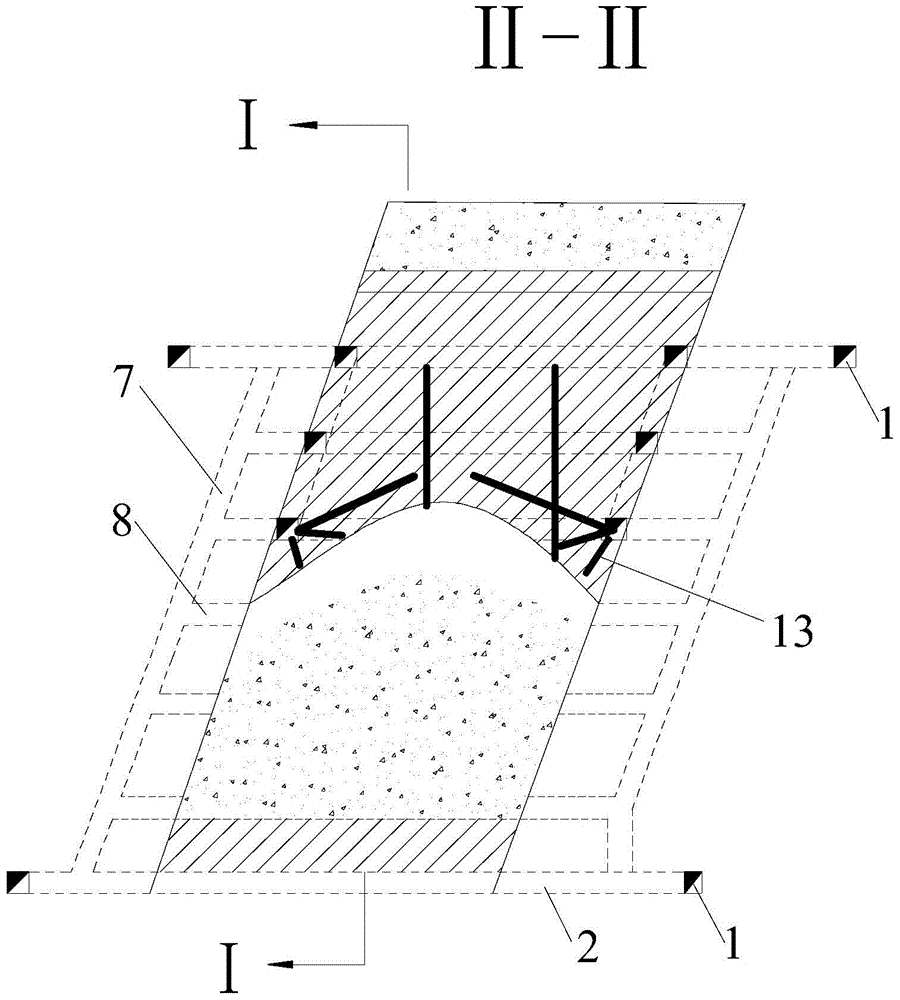

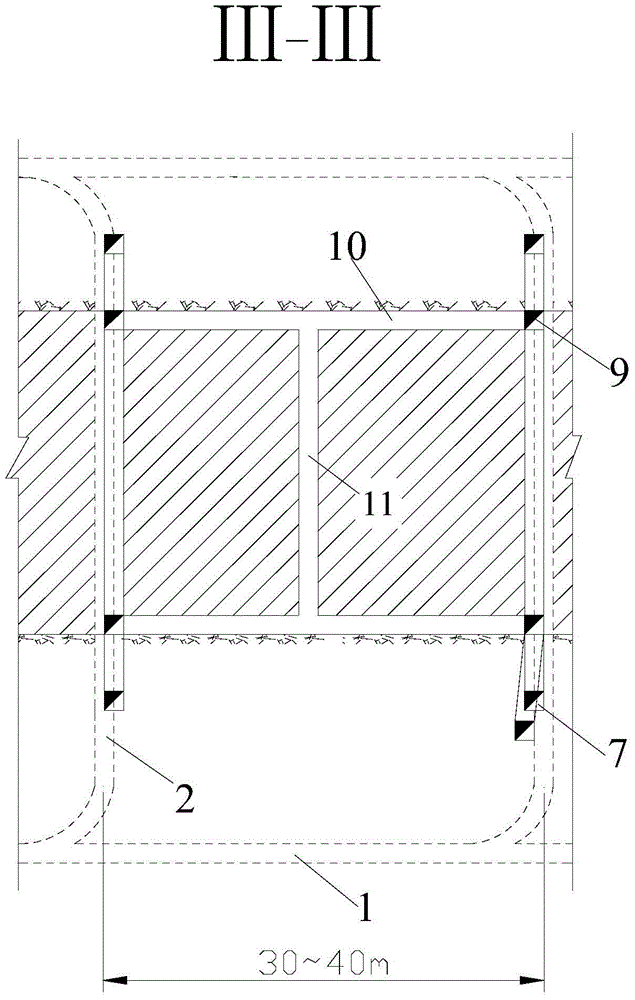

[0019] The specific use case of the mining scheme proposed by the present invention is: for the mining of the above-mentioned types of ore bodies, the stage height is 60-80m, and the length of the ore block is generally 50-60m. When the ore body is broken and the ground pressure is large, it can be reduced to 30- 40m. Use traditional mine development and mining methods to transport the roadway along the strike direction of the ore body during the tunneling stage; 4 cut-off patios are dug at the four corners of the ore block, and the mine block is along the height of every 8-10m from the bottom of the cut-off patio Digging and cutting the roadway around. At the corners, according to the rock collapseability, proper excavation induces pre-split holes. Rock drills are used to drill sector-shaped medium-deep blastholes with a diameter of 45-75mm, and carbon dioxide blasters are used to force pre-splitting and caving of ore bodies that are difficult to collapse naturally, or control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com