Shortwall hydraulic mining method along strike

A coal mining method and hydraulic technology, which are applied to underground coal mining in coal mines and move towards the field of short-wall hydraulic coal mining, can solve the problems of imperfect ventilation system, poor operation safety, and narrow application range, and achieve strong production continuity and production safety. Reliable, adaptable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

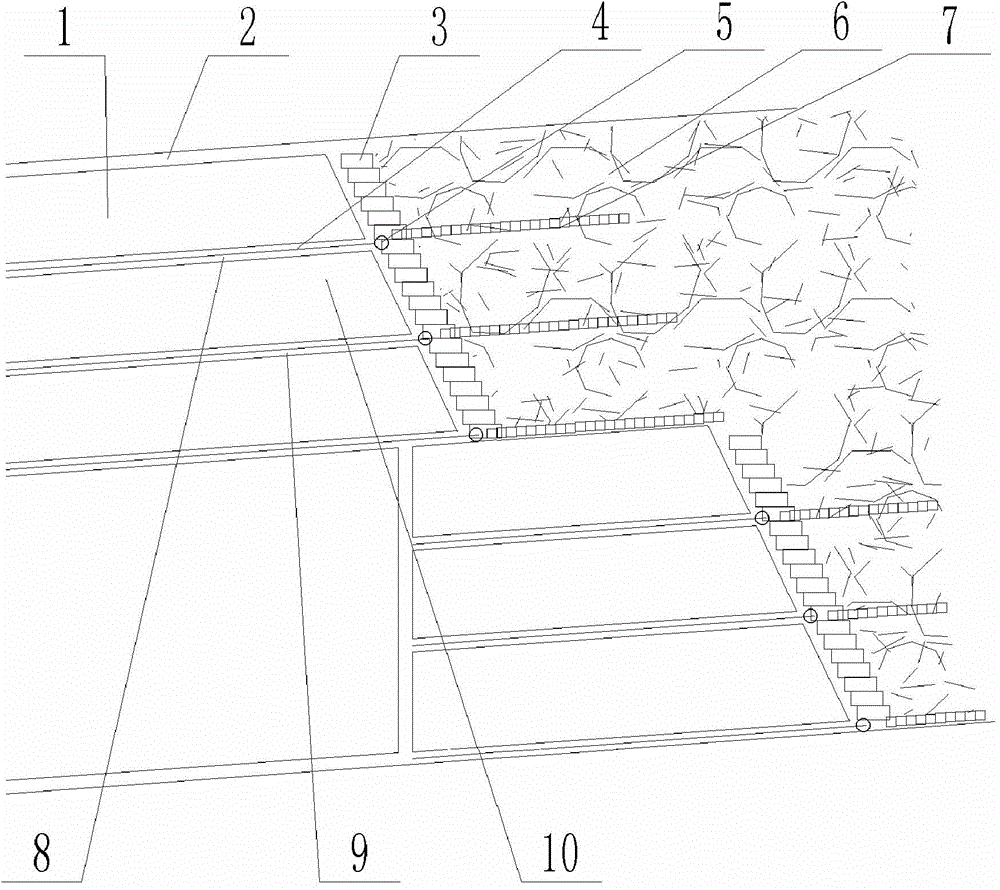

[0020] like figure 1 Shown, a kind of short-wall hydraulic coal mining method comprises the following steps:

[0021] Step 1: In the area where the inclined coal seam is to be mined, along the direction of the coal seam strike, the phase of the hydraulic coal mining face is arranged at a pseudo-incline at an angle of about 10-20° to the coal seam inclination, and the return air channel 2 and the recovery channel are formed to form a small trend stage Coal mining method, each coal seam is jointly arranged for mining, single-wing or double-wing mining of the coal seam, downward mining within the stage, the mining of the first small-stage working face 1 is completed, and then the second small-stage working face 10 is mined; the size of the working face is determined according to the coal seam assigned In general, the inclination length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com