System and method for clearing pulverized coal storage powder by using adjacent furnace negative pressure

A technology for pulverized coal bunkers and adjacent furnaces, which is applied in the direction of combustion methods, fuel supply adjustment, block/powder supply/distribution, etc., which can solve the problems of affecting the maintenance work process, prolonging the shutdown time of the boiler, and long consumption , to achieve the effect of saving time, manpower and material resources, benefiting environmental protection and energy saving of the boiler, and shortening the preparation time for shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

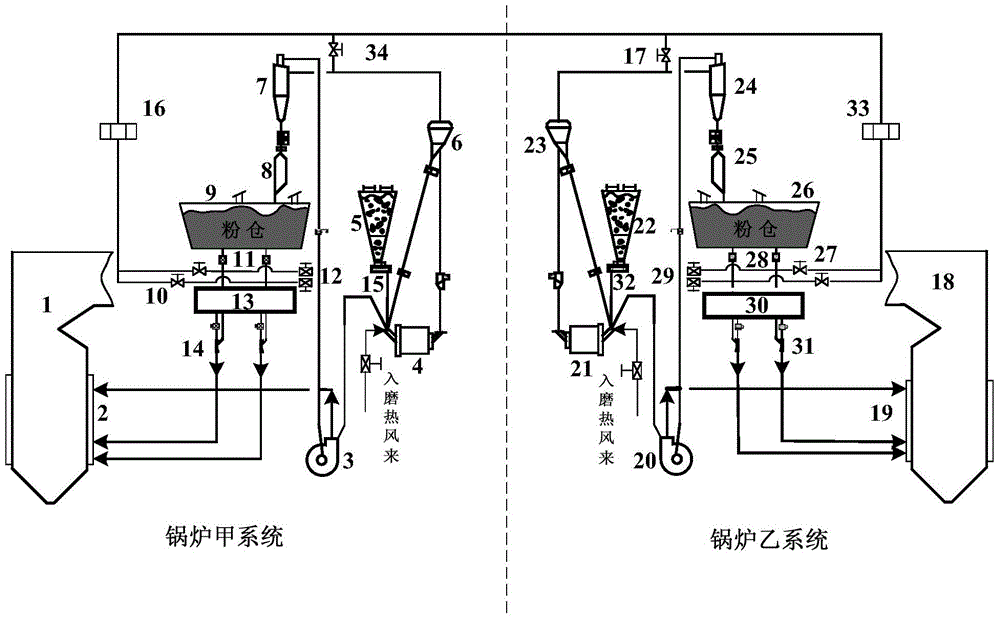

[0025] see figure 1 , the present invention utilizes the negative pressure of the adjacent furnace to remove the powder stored in the pulverized coal bin, which specifically includes a boiler A 1 and its first burner 2, the first powder row fan 3, the first coal mill 4, the first raw coal hopper 5, The first coarse powder separator 6, the first fine powder separator 7, the first sawdust separator 8, the first powder bin 9, the first pulverized coal isolation valve 10 of the powder discharge pipe, the first powder feeder 11, the first discharge Powder pipe cold air regulating valve 12, first primary wind box 13, first air powder mixer 14, first coal feeder 15, first powder discharge pipe wind speed measuring device 16, and first powder discharge pipe adjacent furnace isolation valve 17; It also includes the second burner 19 of boiler second 18 and boiler seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com