Device and method for synchronously measuring concentration, thickness and temperature of liquid film

A synchronous measurement and liquid film technology, applied in measurement devices, instruments, etc., can solve problems such as inability to measure at the same time, difficulty in model establishment and solution, and achieve the effect of increased strength and high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

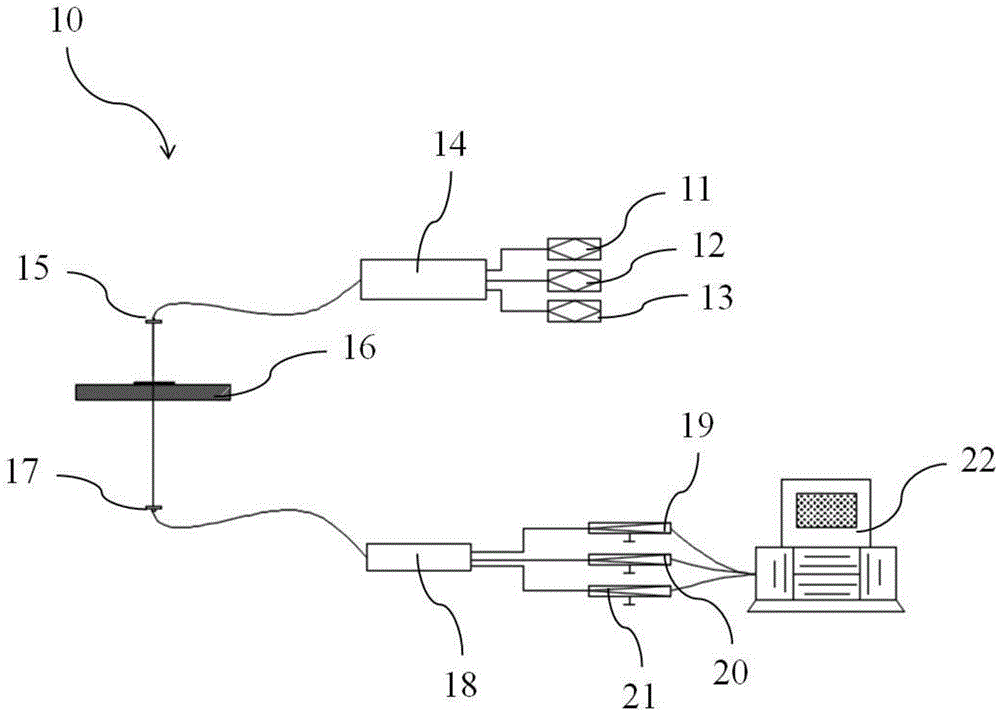

[0018] figure 1 It is the device for synchronously measuring liquid film concentration, thickness and temperature of the embodiment.

[0019] Such as figure 1 As shown, the device 10 for synchronously measuring liquid film concentration, thickness and temperature includes a laser light source 11, a laser light source 12, a laser light source 13, a wavelength division multiplexer 14, a first collimator 15, a liquid film carrier 16, a second collimator Straightener 17, wave splitter 18, spectrum acquisition component 19, spectrum acquisition component 20, spectrum acquisition component 21 and computer 22.

[0020] In this embodiment, the laser light sources 11, 12 and 13 are all semiconductor lasers. The wavelength division multiplexer 14 is connected to the semiconductor laser 11 , the semiconductor laser 12 and the semiconductor laser 13 respectively. The first collimator 15 is connected to the wavelength division multiplexer 14 . The liquid film carrier 16 is arranged dir...

Embodiment 2

[0023] The method of simultaneous measurement of liquid film concentration, thickness and temperature is as follows:

[0024] Step 1, take pure water and urea solution liquid films with mass concentrations of 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, and 50% respectively, and use absorption spectroscopy to measure The device measures the pure water and the above-mentioned urea solution liquid film at a wave number of 6000-8000cm -1 , Absorption coefficient at 20°C, 30°C, 40°C, 50°C.

[0025] Step 2, plot the absorption coefficients of pure water and all urea liquid films at different temperatures against the wave number to obtain the absorption coefficient-wave number curve, compare the absorption coefficient values of all urea liquid films at different wave numbers, and select the wave number ν 1 and ν 2 , so that the rate of change of the absorption coefficient of all urea liquid films at different concentrations and different temperatures to the concentration is zero;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com