Method for measuring P91 steel weld brinell hardness

A Brinell hardness and Brinell hardness tester technology, applied in the direction of testing material hardness, etc., can solve the problems of large gap between measured values, complicated operation, misjudgment of safe operation of boilers, etc., and achieves small errors and accurate measurement results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: The manufacture of P91 steel hardness test block and the establishment of the conversion relationship between Leeb hardness and Brinell hardness:

[0029] The P91 material used in the high temperature header is selected, and the specification is Φ273×28mm. In order to meet the requirements of GB / T17394-1998 "Metal Leeb Hardness Test Method" for hardness samples: the minimum thickness of the sample measured by the impact device type D and DC type Leeb hardness tester is 5mm, and the quality of the sample placed stably > 5kg, according to the density of P91 steel at 20°C is 7.78t / m 3 , the calculated sample size meeting the standard requirements is 210×116×17mm.

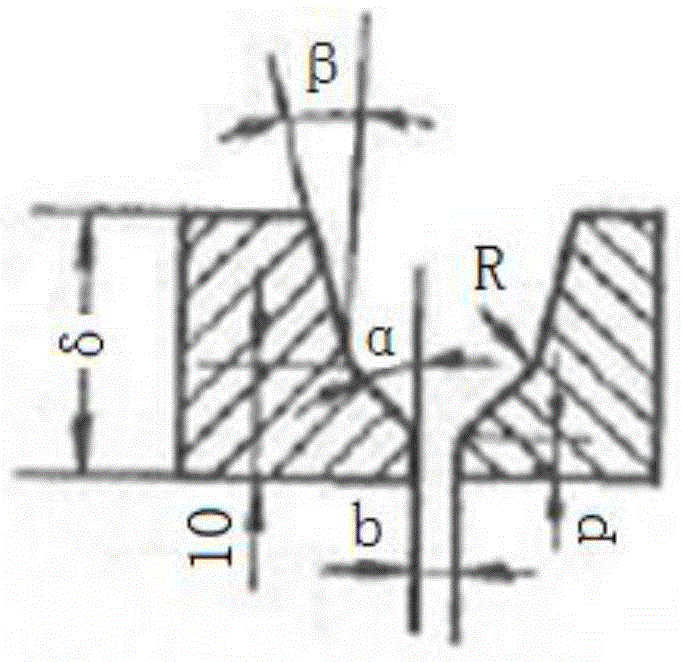

[0030] In order to meet the requirements of welding technology, the processing of the groove of the hardness test block is as follows: figure 1 shown.

[0031] The hardness test block is welded by manual arc welding SMAW, the welding machine model is ZX7-400STG, the welding material is Thyssen C...

Embodiment 2

[0045] Example 2: On-site detection of Brinell hardness of P91 steel weld seam

[0046] The P91 steel base material and weld seam used in power plant boilers are inspected on site, and the area to be inspected is polished to make it have a metallic luster, no scale and other dirt, and the surface roughness is ≤1.6. Utilize the portable Leeb hardness meter to measure the Leeb hardness of the P91 steel weld area to be measured, and obtain the Brinell hardness value according to the linear relational formula determined in embodiment 1, and compare with the actual measured Brinell hardness value, the result See Table 4.

[0047] Table 4 Comparison table of measured Brinell hardness value and calculated Brinell hardness value of P91 steel weld seam

[0048]

[0049] As can be seen from Table 4, according to the conversion relationship formula of HB-HL established by the present invention, the error between the calculated value of the calculated Brinell hardness and the measured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com