Power supply switch control circuit with power down delay function

A power switch, control circuit technology, applied in electrical program control, circuit or fluid pipeline, program control in sequence/logic controllers, etc. Delay time change and other problems, to achieve the effect of configurability, free setting of power-off delay time, and easy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

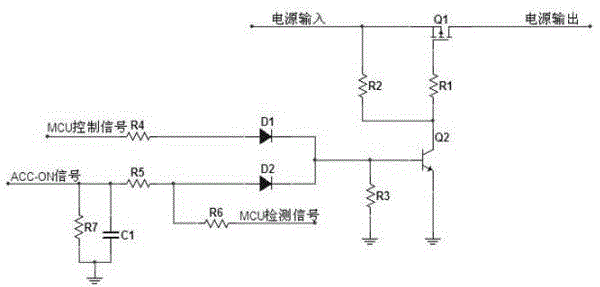

[0009] The invention proposes a power switch control circuit with a power-off delay function, which solves the power supply control problem of the controller from the aspects of power-off delay, dark current reduction and the like. figure 1 It is a circuit disclosed by the invention, and the circuit includes two parts of a level conversion and a power switch.

[0010] The level conversion circuit is composed of C1, D1, D2, R3, R4, R5, and R6. In the power supply system of the vehicle, the standard voltage is generally 12V, so the key signal level is also around 12V, and C1 is here Filter the external key signal. R3, R5, and D2 form a voltage divider circuit to provide a suitable drive level for the conduction of Q2. R6 is the current limiting resistor for the signal to prevent the IO port of the MCU from being burned by excessive current. . R3, R4, and D1 form a voltage divider circuit for the MCU control signal, which is the same as the aforementioned voltage divider circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com