Bridge precast concrete member monitoring system based on two-dimensional code and control method thereof

A prefabricated concrete and monitoring system technology, applied in the direction of instruments, data processing applications, resources, etc., can solve problems affecting the construction period, backlog of components, extensive management, etc., to achieve the effect of saving construction period and construction cost, and reducing backlog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

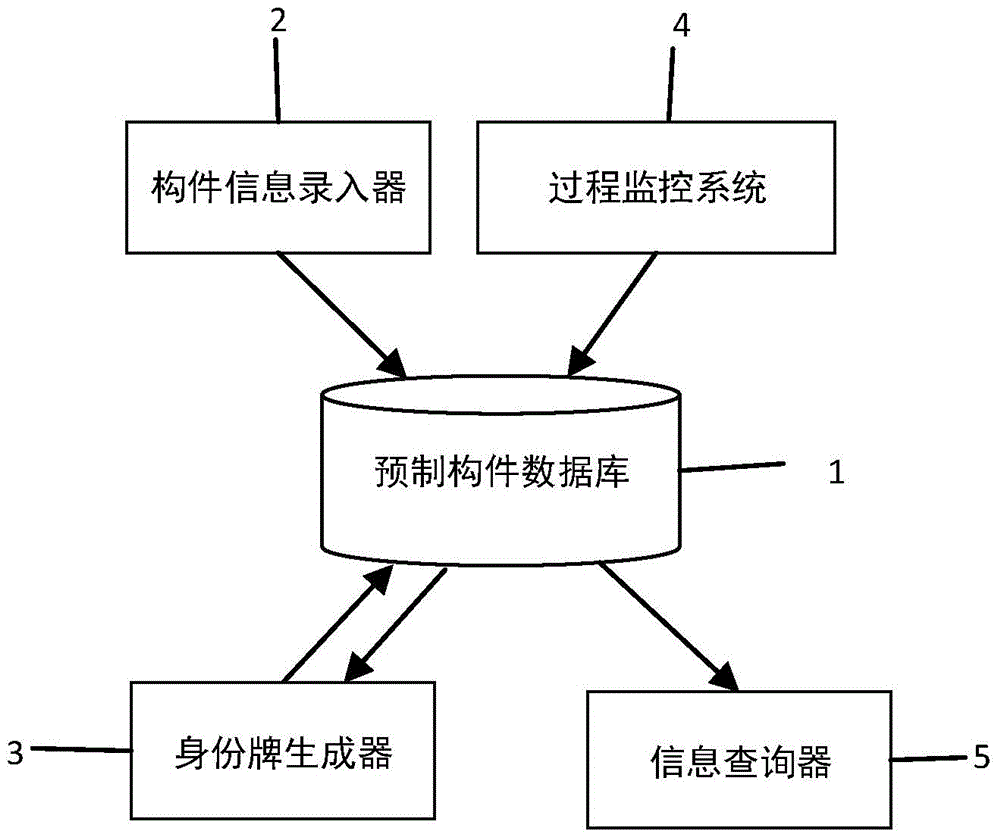

[0035] A two-dimensional code-based monitoring system for bridge precast concrete components, including:

[0036] Database (prefabricated component database) 1, used to save material information of bridge precast concrete components (hereinafter referred to as prefabricated components);

[0037] The information input device 2 includes a human-computer interaction interface for manually inputting material information and a storage module for automatically storing the manually input material information into the database 1;

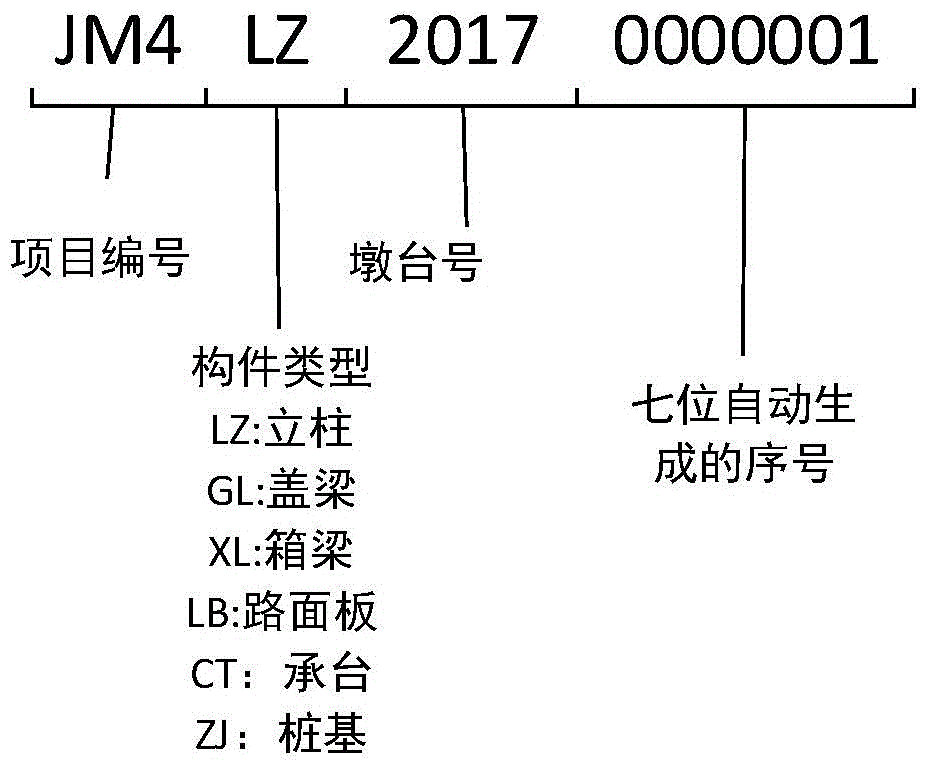

[0038] ID card generator 3, according to the material information of the prefabricated components in the database 1, automatically generates a unique code, a corresponding two-dimensional code and an ID card for each prefabricated component;

[0039] The process monitoring system 4 is used to record and monitor the process information of the production, transportation, storage and installation of prefabricated components, and store the process information i...

Embodiment 2

[0049] The control method of the bridge precast concrete member monitoring system based on the two-dimensional code, the steps are as follows:

[0050] S101: The technician uses the information input device 2 to input the two-dimensional code information of the prefabricated component, and the information input device 2 will automatically store the input information into the prefabricated component table in the database 1 . For example, manual entry such as figure 2 The project number shown is JM4, and the column prefabricated component information with abutment number 20.

[0051] S102: The administrator uses the identity card generator 3 to select several prefabricated components that need to be processed, automatically generates the electronic version of the processing order and the identity card, and prints the paper version of the processing order and the identity card. For example, generate as image 3 Identification plate for precast unit number JMLZ200000001 shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com