Structure of a superjunction mosfet device

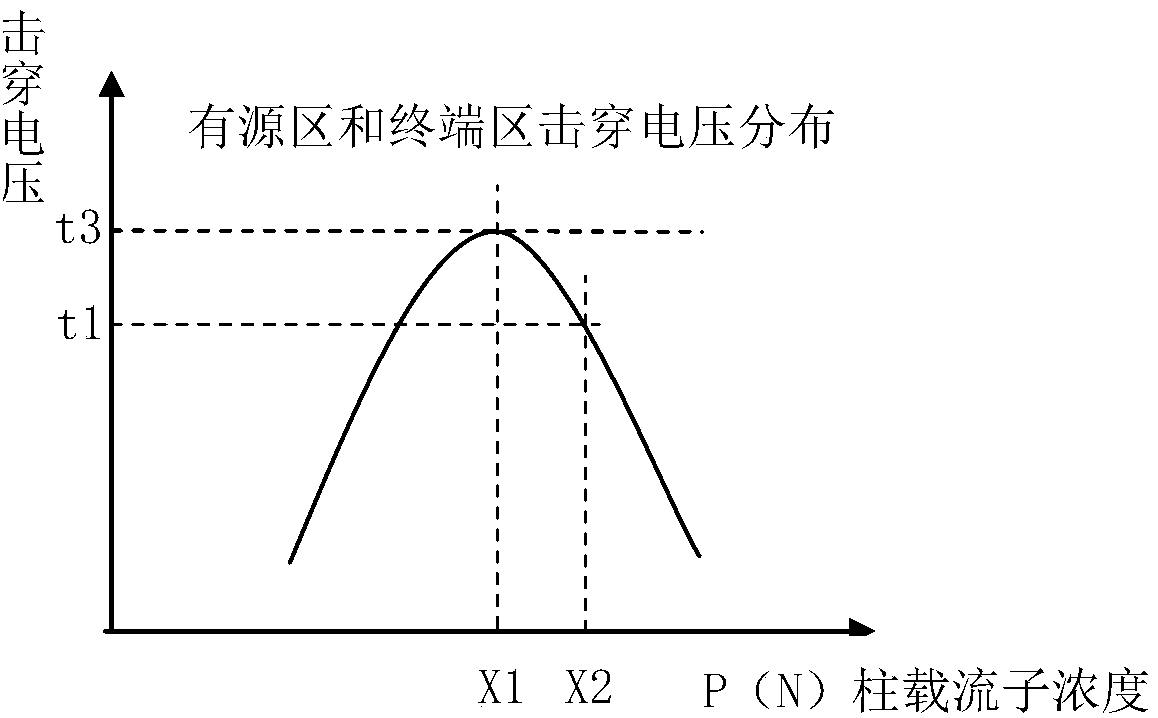

A super junction and device technology, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor device stability, relatively large breakdown voltage fluctuations, and difficulty in controlling the stability of doping concentration of super junction MOSFETs. Very poor, improved uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

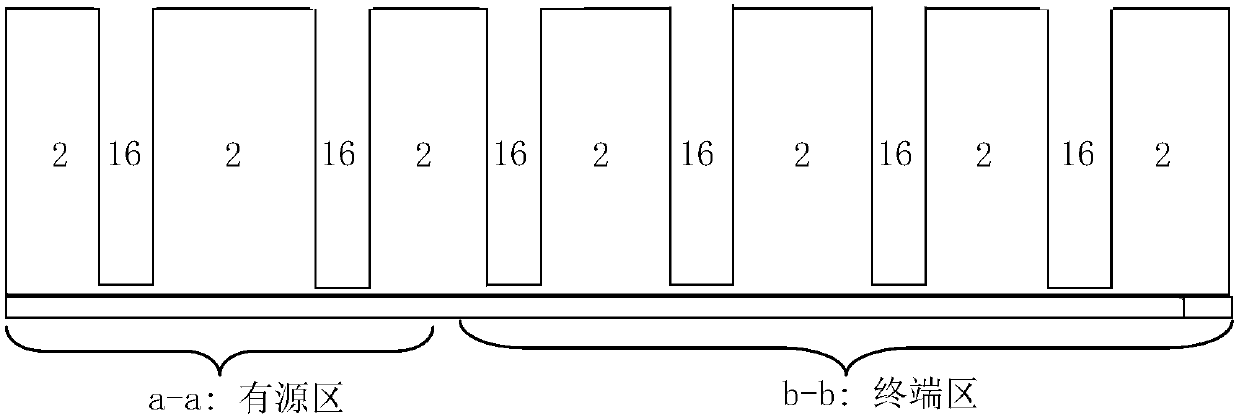

[0023] See Figure 2-5 Shown, the superjunction MOSFET device of the present invention, its specific manufacturing process steps are:

[0024] Step 1, growing a first semiconductor layer with a thickness of 10-100 microns on the semiconductor substrate, such as figure 2 As shown, and grow a layer of dielectric film on the first semiconductor layer (not shown in the figure).

[0025] The first semiconductor layer and the semiconductor substrate have a first doping type. A typical first semiconductor layer is an N-type silicon epitaxial layer, and a typical semiconductor substrate is an N-type silicon substrate. The doping concentration of the first semiconductor layer is set to m. The carrier concentration of the semiconductor base is higher than that of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com