A solid non-polarized electrode resistant to deep-sea pressure and its preparation method

A polarized electrode, solid technology, applied in the field of materials, can solve the problems of weak resistance to mechanical vibration, affect performance, destroy electrode cores, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

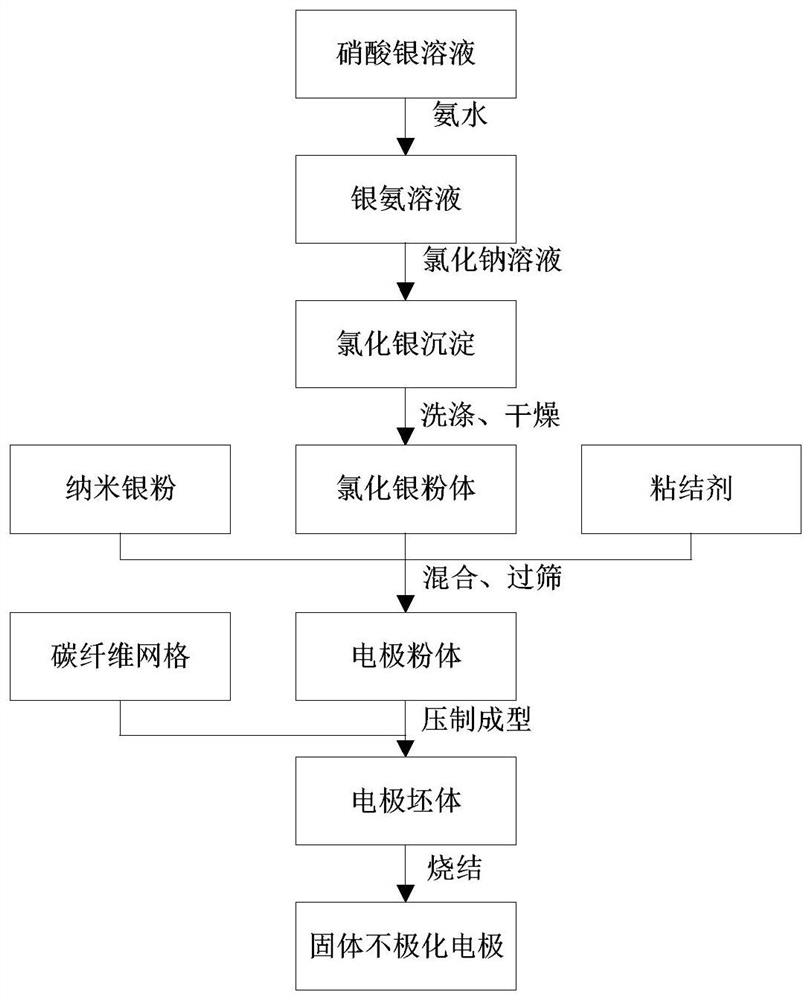

[0020]Please refer tofigure 1 The embodiment of the present invention provides a method for preparing a solid non-polarized electrode resistant to deep sea pressure, which includes the following steps:

[0021]Step S1, first dissolve silver nitrate in deionized water to prepare a silver nitrate solution, then add a small amount of ammonia to the solution to obtain a brown precipitate, add excess dilute ammonia to make the brown precipitate just dissolve, and obtain a silver ammonia solution;

[0022]In step S2, the sodium chloride solution and the silver ammonia solution are thoroughly mixed according to a mass ratio of 1:2.0 to 1:3.5 to obtain a silver chloride precipitate;

[0023]Step S3, washing the silver chloride precipitate repeatedly, freeze-drying or spray-drying, to obtain nano-silver chloride powder;

[0024]Step S4, the nano silver powder and the silver chloride powder are proportioned according to the mass ratio of 1:0.8 to 1:2.5, and then a binder with a mass percentage of 5-15% i...

Embodiment 1

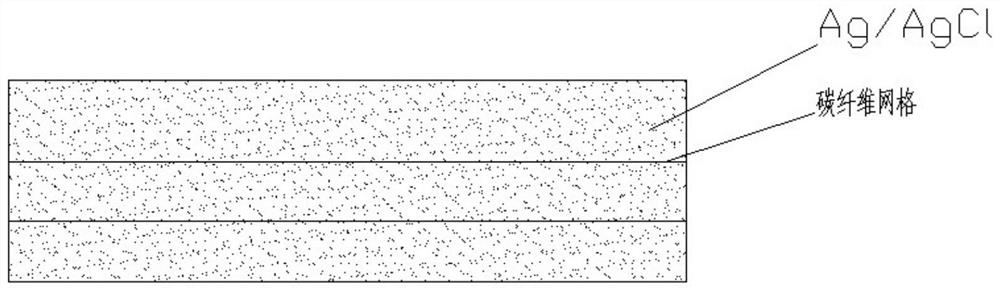

[0029]Weigh 11.85g silver nitrate and dissolve it in deionized water to prepare 0.2mol / L silver nitrate solution. Add ammonia solution to form brown precipitate, continue to add excess dilute ammonia water to make the brown precipitate just dissolve and obtain silver ammonia solution; weigh 4.08 g sodium chloride to prepare a 0.2mol / L sodium chloride solution, pour the sodium chloride solution into the silver ammonia solution, and stir quickly to obtain a silver chloride precipitate; wash the silver chloride precipitate repeatedly and dry it by spray drying , Get silver chloride powder; weigh 8g silver chloride powder and 10g silver powder, add polyvinyl alcohol, mix well, sieving, the sieve is 60 meshes, get electrode powder; the electrode powder and carbon fiber grid Alternately placed in the mold, molded under a pressure of 100MPa, and then sintered at 400°C for 1 hour in a nitrogen environment to obtain a solid non-polarized electrode.

Embodiment 2

[0031]Weigh 10g of silver nitrate and dissolve it in deionized water to prepare 0.2mol / L silver nitrate solution. Add ammonia solution to form brown precipitate, continue to add excess dilute ammonia to make the brown precipitate just dissolve and obtain silver ammonia solution; weigh 2.86g Sodium chloride to prepare 0.2mol / L sodium chloride solution, pour the sodium chloride solution into the silver ammonia solution and stir quickly to obtain silver chloride precipitate; wash the silver chloride precipitate repeatedly and dry it by freeze drying, Obtain silver chloride powder; Weigh 5g silver chloride powder and 4g silver powder, add cellulose, mix thoroughly, sieving, the sieve is 100 meshes, obtain electrode powder; Place electrode powder and carbon fiber grid alternately In a mold, it was molded under a pressure of 200 MPa, and then sintered at 500°C for 2 hours under helium protection to obtain a solid non-polarized electrode.

[0032]referenceFigure 4, Which is the typical range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com