Non-polarized electrode with service life prolonged by adding electrolyte solution

An electrolytic solution and polarized electrode technology, applied in the field of semiconductors, can solve the problems of short service life of solid non-polarized electrodes, electrodes rising to tens or even tens of millivolts, and electrodes that cannot be used again. performance, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

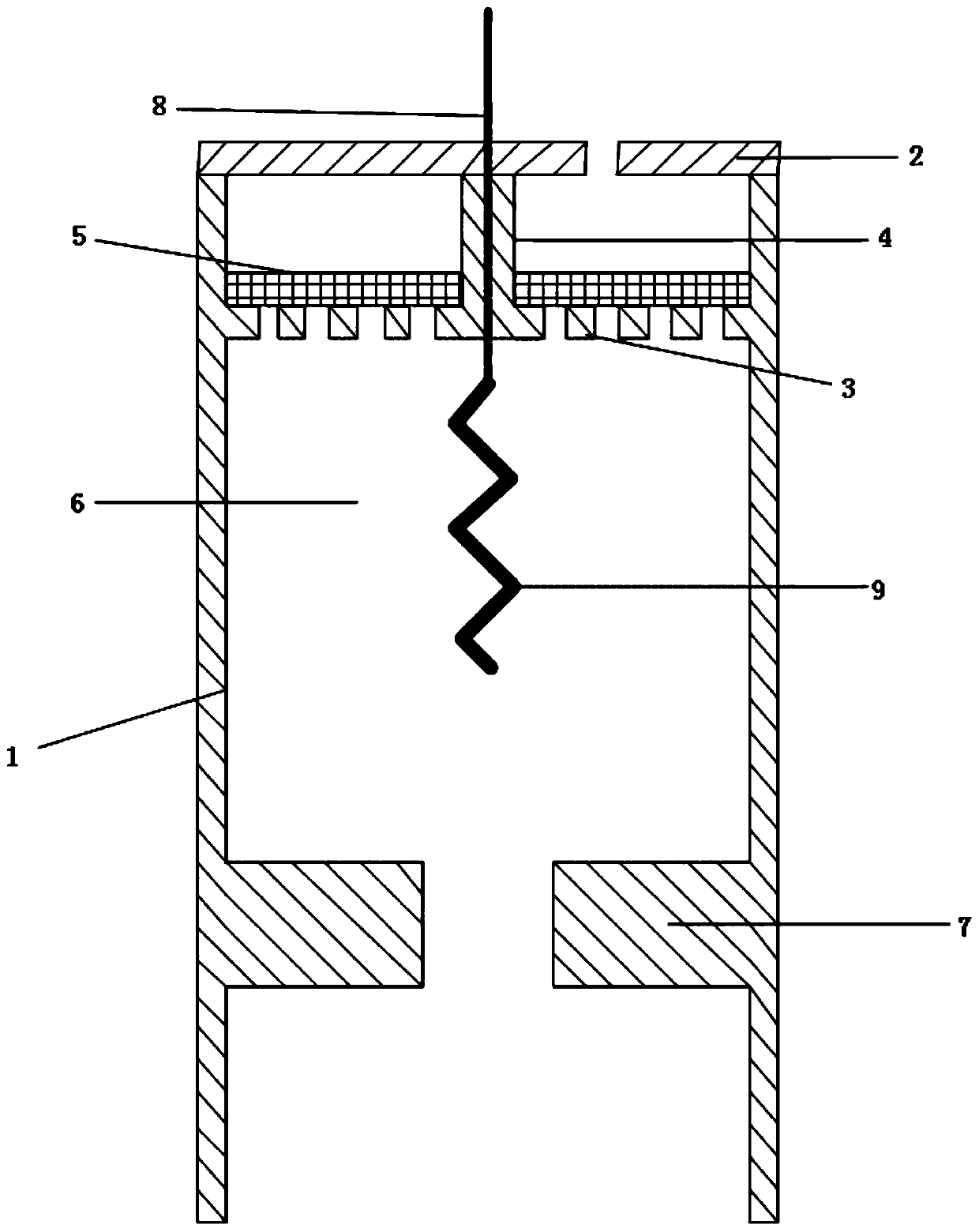

[0050] see figure 1 , a non-polarized electrode whose service life is extended by adding an electrolyte solution, mainly includes an electrode case 1, a top cover 2, a perforated separator 3, a waterproof tube 4, a sponge 5, a solid electrolyte 6, an isolation ring 7 and a precursor electrode.

[0051] Further, the electrode casing 1, the top cover 2, the separator with holes 3, the waterproof pipe 4 and the isolation ring 7 are made by 3D printing technology.

[0052] Further, the perforated separator 3 , the electrode case 1 , the waterproof tube 4 and the isolation ring 7 are an integral body, which is printed out by using 3D printing technology. This part is the container used to hold the solid electrolyte. The inner diameter of the container is 72 mm, the outer diameter is 76 mm, and the height of the container is 100 mm.

[0053] The upper end of the electrode casing 1 is closed and installed with a top cover 2 .

[0054] A horizontal perforated separator 3 is instal...

Embodiment 2

[0078] A non-polarized electrode whose service life is extended by adding an electrolyte solution, mainly including an electrode case 1, a top cover 2, a separator with holes 3, a waterproof tube 4, a sponge 5, a solid electrolyte 6, an isolation ring 7 and a precursor electrode .

[0079] The upper end of the electrode casing 1 is closed and installed with a top cover 2 .

[0080] A horizontal perforated separator 3 is installed inside the electrode case 1 , so that the top cover 2 , the electrode case 1 and the perforated separator 3 form an inner cavity.

[0081] A horizontal spacer ring 7 is installed on the lower end of the electrode casing 1 .

[0082] The top cover 2 has a hole I for the precursor electrode to pass through and a hole II for the electrolyte solution to flow into the cavity.

[0083] The perforated separator 3 is provided with a hole III for the passage of the precursor electrode and n holes IV for the inflow of the electrolyte solution. n≥2, n is a na...

Embodiment 3

[0091] A non-polarized electrode whose service life is extended by adding an electrolyte solution. The main structure is shown in Example 2, wherein the precursor electrode includes vertical metal wires and helical metal wires. The helical wire is located inside the electrode casing. The upper end of the helical wire is connected to the lower end of the vertical wire. The upper end of the vertical metal wire passes through the hole III, the waterproof pipe 4 and the hole I to pass through the electrode casing 1 in sequence.

[0092] The material of the vertical metal wire is copper. The material of the spiral wire is lead.

[0093] The method for connecting the vertical wire and the helical wire can be welding, or sol high-temperature bonding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com