A kind of negative electrode active material, negative electrode sheet and its preparation method and lithium ion battery

A technology of negative electrode active material and conductive agent, applied in the field of lithium battery, can solve the problems of limiting wide application, increasing battery manufacturing cost, affecting the rate charging and discharging performance of lithium battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

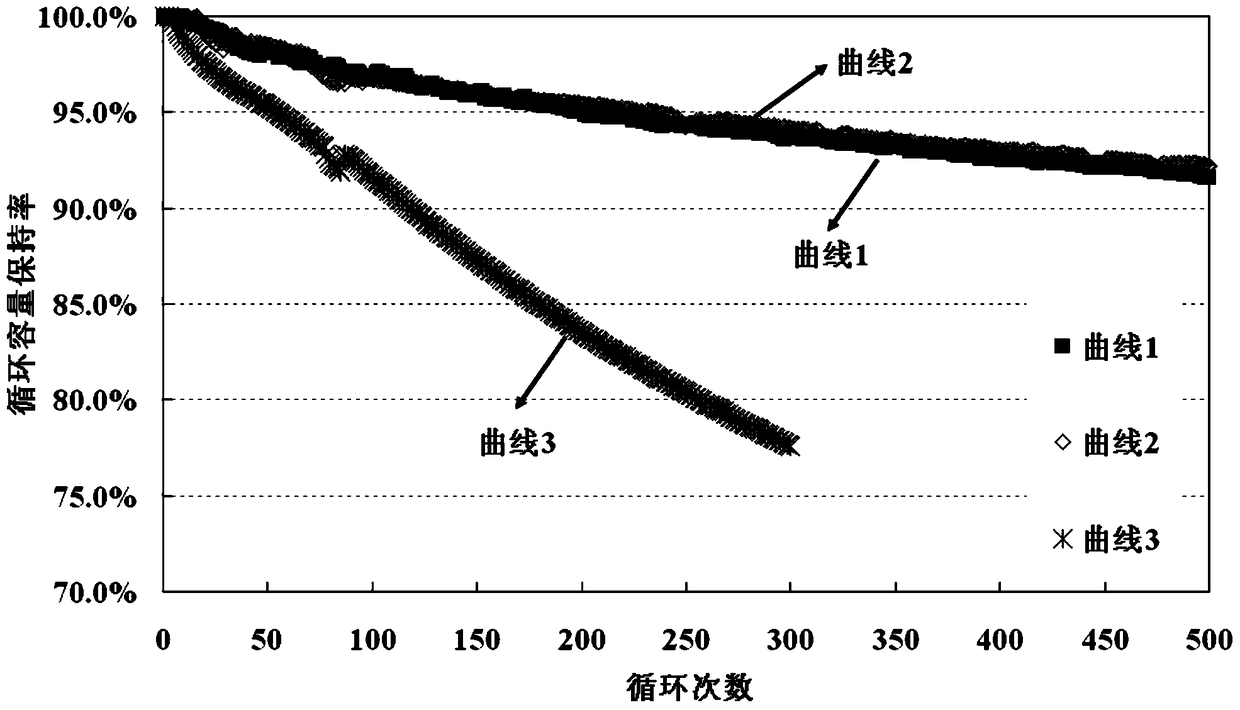

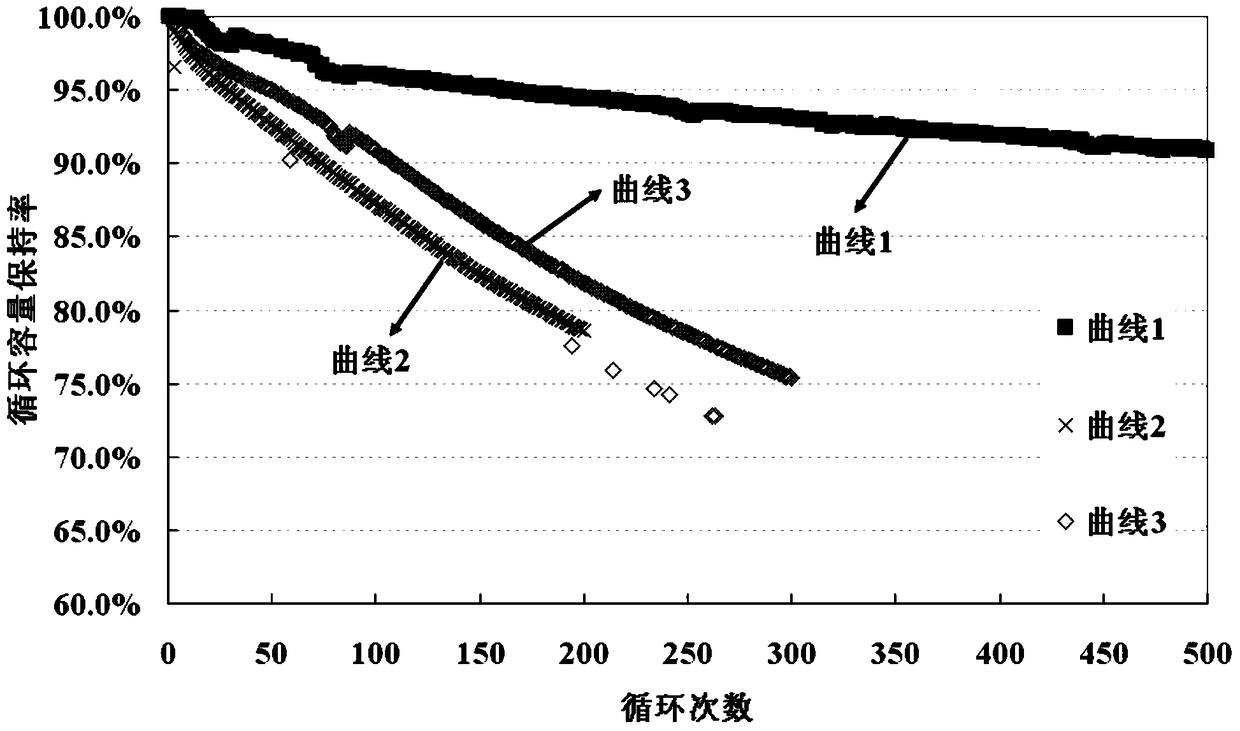

Embodiment 1

[0073] A method for preparing a lithium-ion battery negative pole piece, comprising:

[0074] (1) Physically and mechanically mix natural graphite, artificial graphite and conductive graphite at a mass ratio of 60:35:5 to form a composite carbon material, and then pass the composite carbon material into oxygen and nitrogen at 600°C for treatment, and after cooling the above materials Isostatic pressing treatment is performed to obtain a block-shaped pressed product, the treatment temperature is 200° C., the treatment pressure is 100.0 MPa, and the treatment time is 2.0 h. Put the above-mentioned square-shaped molded product at 950°C for 240 hours of thermal roasting treatment, and after cooling to room temperature, crush and sieve the above-mentioned molded product to form a product containing -COOH, =O, -OH oxygen-containing organic groups on the surface. Negative electrode active material; determined by XRD, the compacted density is 1.70g / cm 3 , the orientation index OI of ...

Embodiment 2

[0087] A method for preparing a lithium-ion battery negative pole piece, comprising:

[0088] (1) Physically and mechanically mix natural graphite, mesocarbon microspheres and artificial graphite at a mass ratio of 60:20:20 to form a composite carbon material, and then pass the composite carbon material into oxygen and argon at 580°C for cooling Afterwards, the above-mentioned material is subjected to hot molding treatment to obtain a cylindrical molded product. The treatment temperature is 400°C, the treatment pressure is 200.0MPa, and the treatment time is 0.5h. Put the above-mentioned cylindrical molded product at 500°C for 360 hours of thermal roasting treatment, and after cooling to room temperature, crush and sieve the above-mentioned molded product to form a surface containing -COOH, =O, -OH and -CHO oxygen-containing organic compounds The negative active material of the group; as determined by XRD, the compacted density is 1.65g / cm 3 , the orientation index OI of the ...

Embodiment 3

[0101] A method for preparing a lithium-ion battery negative pole piece, comprising:

[0102] (1) Natural graphite, artificial graphite and soft carbon are physically and mechanically mixed at a mass ratio of 35:55:10 and then mechanically fused with 5% silicon oxide to form a eutectic composite material, and the composite carbon material is passed through at 800°C Add chlorine gas for treatment, and after cooling, carry out isostatic pressing treatment on the above-mentioned material to obtain a square-shaped pressed product. The treatment temperature is 150°C, the treatment pressure is 300.0MPa, and the treatment time is 2.0h. Put the above-mentioned square-shaped molded product at 1200°C for 60 hours of thermal roasting treatment, and after cooling to room temperature, crush and sieve the above-mentioned molded product to form -COOH, =O, -OH oxygen-containing organic groups on the surface. Negative electrode active material; determined by XRD, the compacted density is 1.60g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com