Hybrid drive train for a vehicle, vehicle, method of operation and retrofitting

A transmission system and vehicle technology, applied in the field of transmission system, can solve the problems of insufficient durability of the power output device, limited space for components of the kinetic energy recovery system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

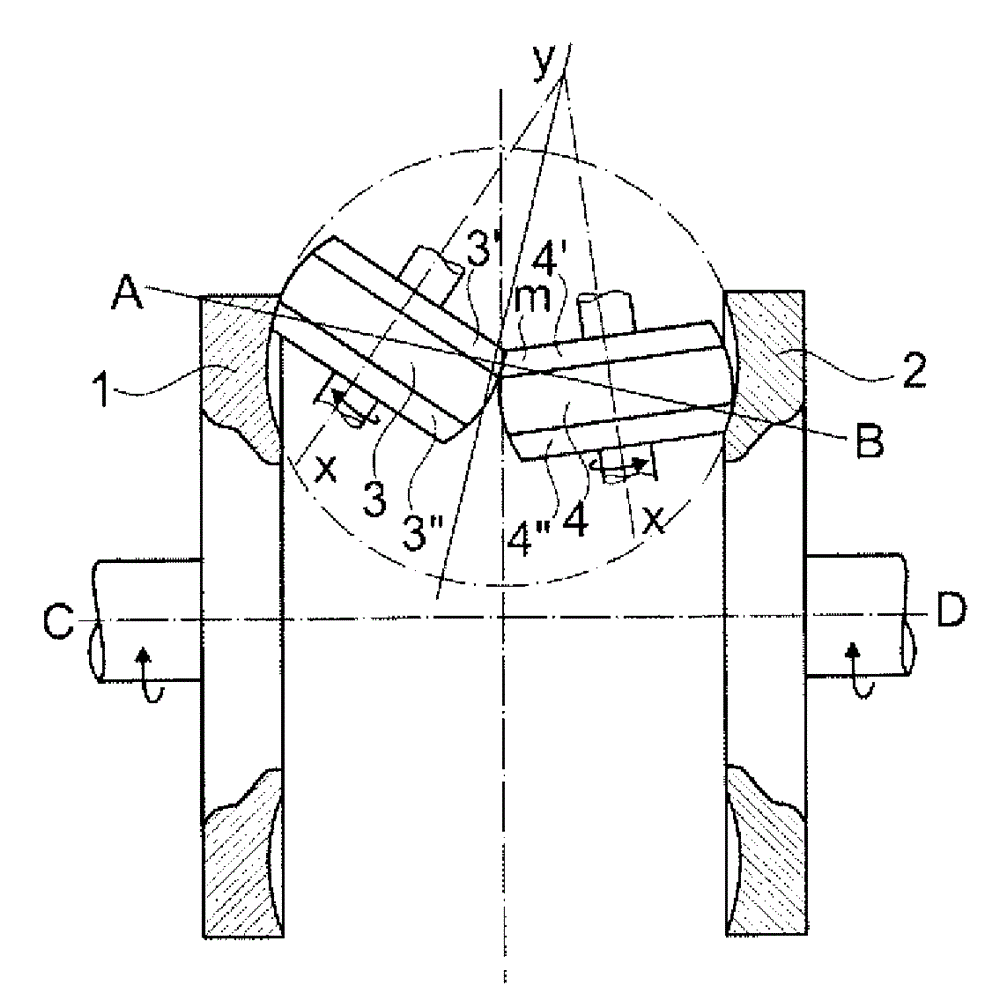

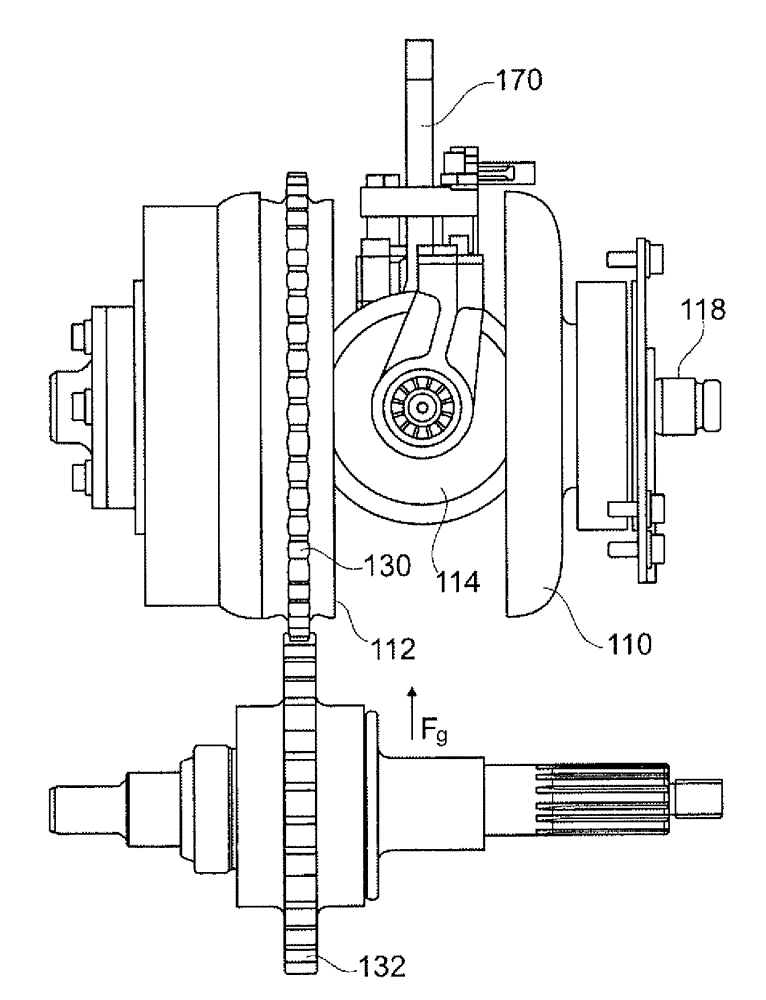

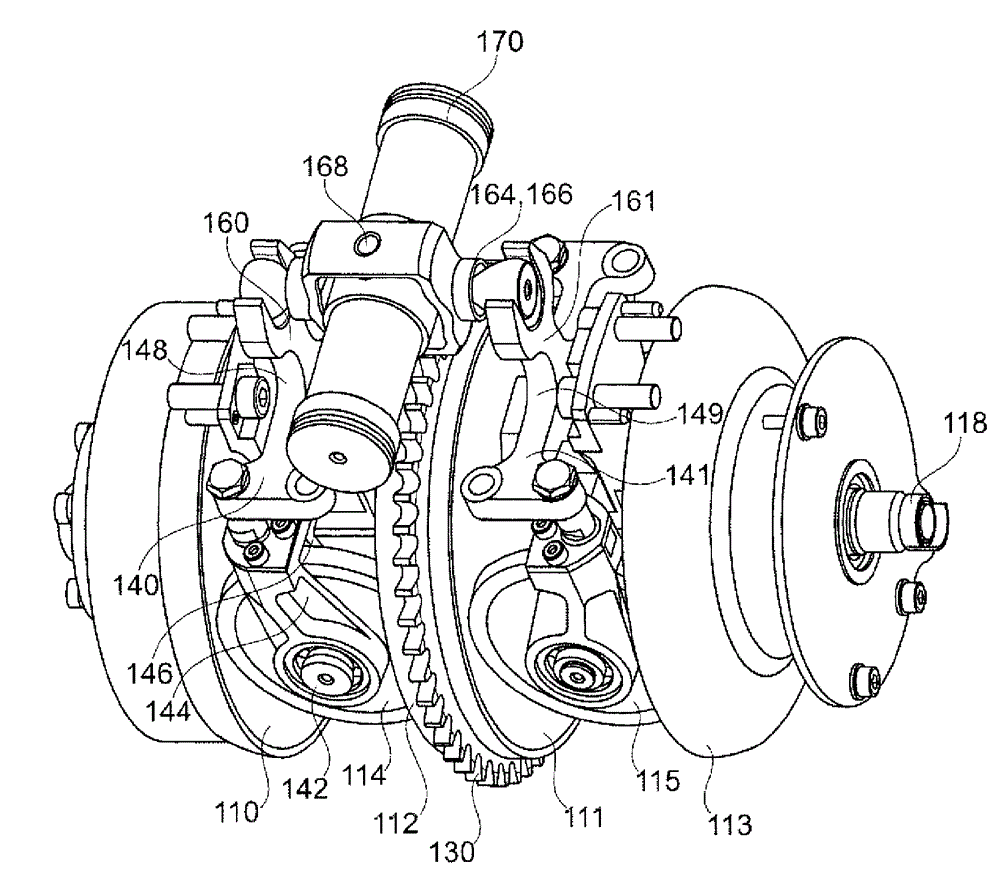

[0067] refer to figure 1 , Embodiments of the present invention are constructed in the drive train of a single-deck passenger vehicle. drive system in figure 1 is shown with the rear of the vehicle towards the top of the figure, and with the vehicle's front-rear axis extending vertically with respect to the figure.

[0068] The drive train includes an internal combustion engine 10 mounted longitudinally at the rear of the vehicle. The output shaft extends in a forward direction to connect to the multi-speed vehicle transmission 12 through a coupling such as a torque converter or a clutch. The output from the vehicle transmission 12 passes through the layshaft 34 (only on image 3 and Figure 4 shown in ) to the transfer case 14. From the transfer case 14 , the transmission passes through the propeller shaft 16 to the final drive unit 18 housed in the live axle 20 . Inside the axle 20 the transmission is transmitted from the final drive unit to the driven road wheels 22 v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com