Three-dimensional food printer

A printer and food technology, applied in the field of 3D printers, can solve problems such as difficult promotion, limited volume, troublesome operation, etc., and achieve the effect of easy promotion and application and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

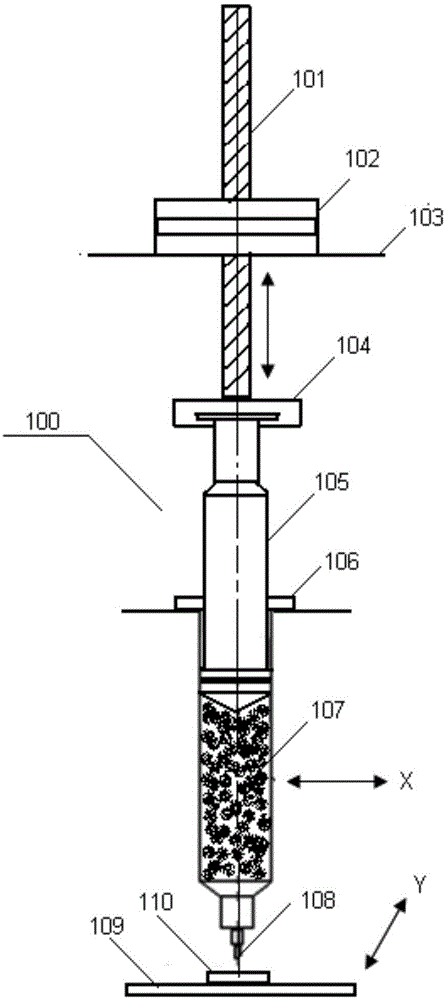

[0038] The present invention will be further described below with reference to the accompanying drawings and embodiments.

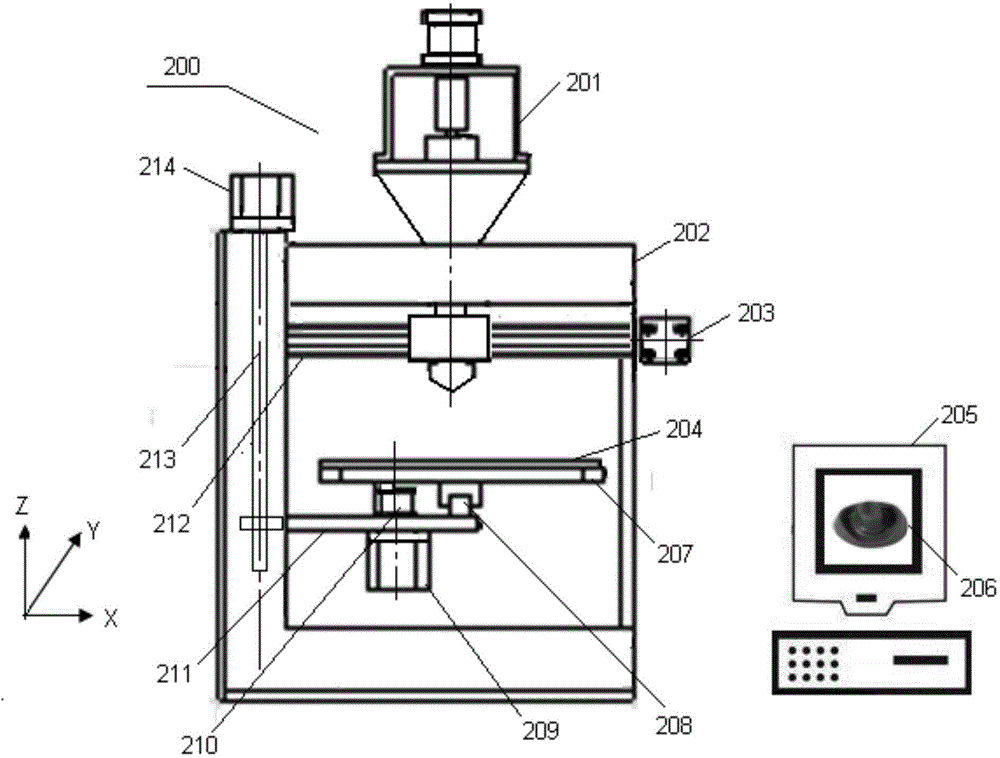

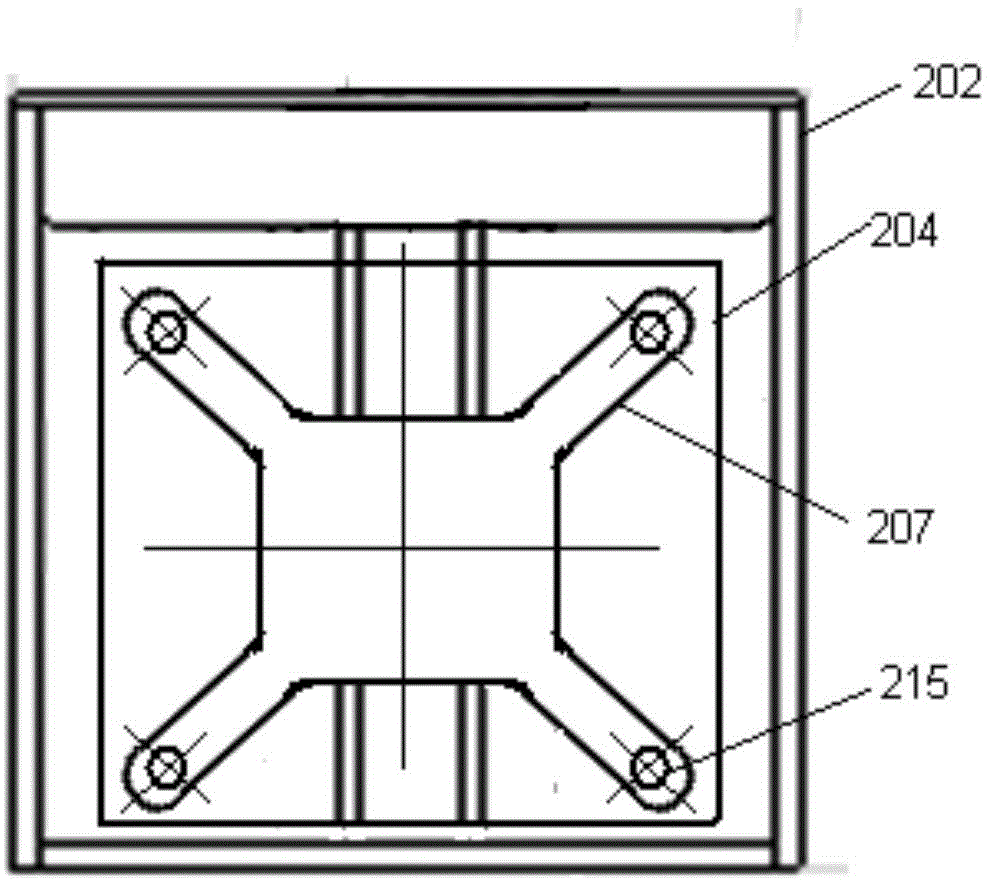

[0039] figure 2 A schematic composition diagram of an embodiment of the 3D chocolate food printer of the present invention is shown. See figure 2 , the 3D chocolate food printer 200 of this embodiment mainly includes: a spray head 201, the X-direction drive stepping motor 203 of the spray head and the toothed belt transmission mechanism 212, the Y-direction drive stepping motor 209 of the platen 207 and the base plate 204 and the toothed belt drive mechanism 212 The belt transmission mechanism 210, the Z-direction drive of the platen 207, the base plate 204 and the pallet 211 drive the stepping motor 214 and the ball screw transmission mechanism 213, the body 202 and the computer numerical control system 205 and so on.

[0040] The specific structures of the X-axis drive system, Y-axis drive system and Z-axis drive system in the printer are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com