Juicy beef ball and preparation method thereof

A technology for urination meatballs and minced meat, which is applied in the field of preparation of urination meatball skins, can solve the problems of affecting the surface smoothness of fish balls, the appearance of the product is not smooth enough, the mouthfeel is soft and inflexible, and the like. fine surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

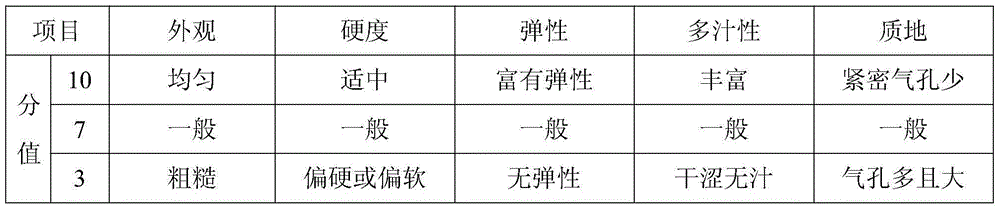

Examples

Embodiment 1

[0046] 1. Skin raw material formula: beef 30kg, pork No. 4 meat 25kg, chicken breast 17.5kg, cassava modified starch 7.5kg, soybean protein isolate 3.5kg, pig fat meat 12.5kg, ice-water mixture 7.5kg, salt 2kg, pyrophosphoric acid Sodium 0.25kg, other seasonings 3.5kg, white sugar 2275g, monosodium glutamate 927.5g, five-spice powder 52.5g, white pepper 262.5g.

[0047] Filling raw material formula: 32.5kg of pork fat, 27.5kg of No. 4 pork, 12.5kg of frozen soup, 2kg of fried shallots, 3kg of sugar, 2kg of monosodium glutamate, 7.5kg of soy sauce, and 3.5kg of soybean protein isolate.

[0048] Wherein, the frozen soup is thick soup made from pig bone, carrageenan and water in a ratio of 10:1:20, frozen into blocks and chopped into granules.

[0049] 2. Prepare the skin slurry:

[0050] The beef, pig No. 4 meat and chicken breast meat used to form the outer skin are cleaned respectively, and they are twisted into minced meat particles with a meat grinder. The particle size of ...

Embodiment 2

[0070] 1. Raw material formula: 25kg of beef, 20kg of pork No. 4 meat, 15kg of chicken breast, 5kg of cassava modified starch, 2kg of soybean protein isolate, 10kg of pork fat, 5kg of ice-water mixture, 1kg of salt, 0.2kg of sodium tripolyphosphate, Other seasonings 2kg, sugar 1200g, monosodium glutamate 400g, five-spice powder 20g, white pepper powder 100g.

[0071] Filling raw material formula: 30kg of pork fat, 25kg of No. 4 pork, 10kg of frozen soup, 1kg of fried shallots, 2kg of sugar, 1kg of monosodium glutamate, 5kg of soy sauce, and 2kg of soybean protein isolate.

[0072] Wherein, the frozen soup is thick soup made from pig bone, carrageenan and water in a ratio of 10:1:20, frozen into blocks and chopped into granules.

[0073] 2. Prepare the skin slurry:

[0074] The beef, pig No. 4 meat and chicken breast meat used to form the outer skin are cleaned respectively, and they are twisted into minced meat particles with a meat grinder. The particle size of the minced be...

Embodiment 3

[0094] 1. Raw material formula: beef 35kg, pork No. 4 meat 30kg, chicken breast 20kg, cassava modified starch 10kg, soybean protein isolate 5kg, pig fat meat 15kg, ice-water mixture 10kg, salt 3kg, sodium hexametaphosphate 0.3kg, Other seasonings 5kg, sugar 3500g, monosodium glutamate 1650g, five-spice powder 100g, white pepper 500g.

[0095] Filling raw material formula: 35kg of pig fat meat, 30kg of pig No. 4 meat, 15kg of frozen soup, 3kg of fried shallots, 4kg of sugar, 3kg of monosodium glutamate, 10kg of soy sauce, and 5kg of soybean protein isolate.

[0096] Wherein, the frozen soup is thick soup made from pig bone, carrageenan and water in a ratio of 10:1:20, frozen into blocks and chopped into granules.

[0097] 2. Prepare the skin slurry:

[0098] The beef, pig No. 4 meat and chicken breast meat used to form the outer skin are cleaned respectively, and they are twisted into minced meat particles with a meat grinder. The particle size of the minced beef and chicken b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Elastic value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com