Gas Processing Apparatus

A gas treatment and gas technology, applied in the field of gas treatment devices, can solve the problems of maintenance time, cost increase, product cost competitiveness decline, product cost increase, etc., to improve the efficiency of detoxification, easy management, prevent The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

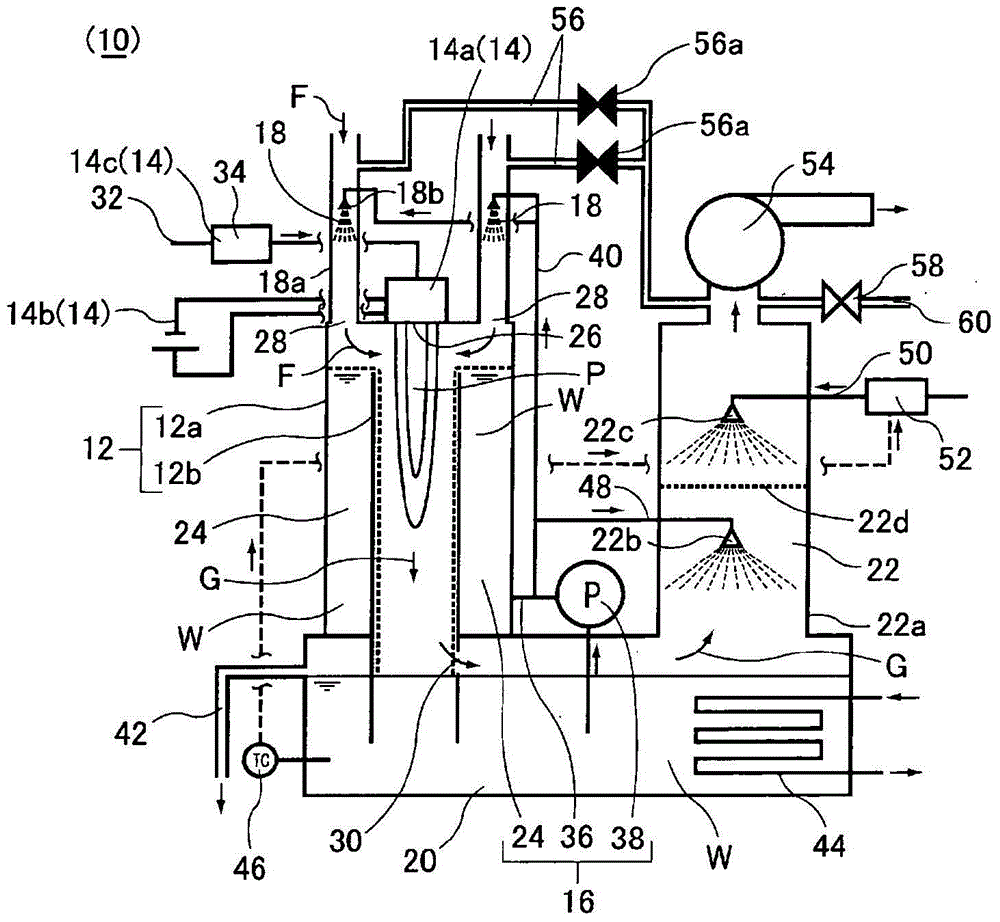

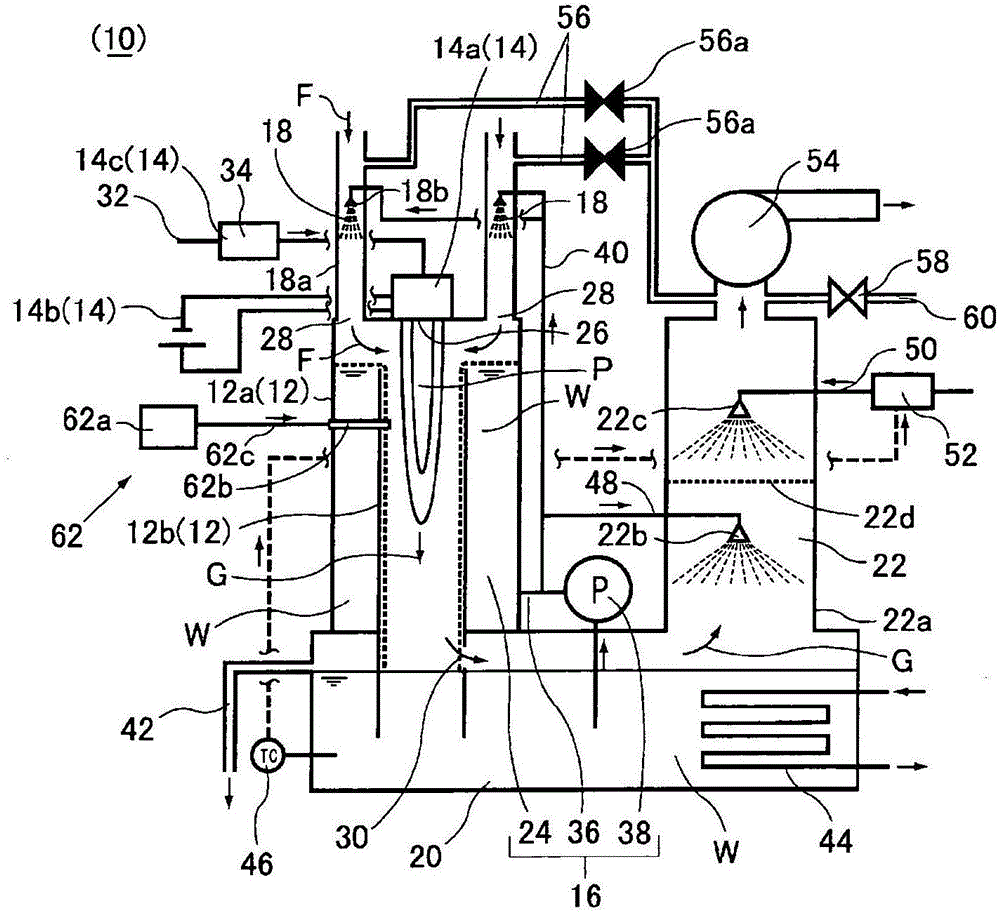

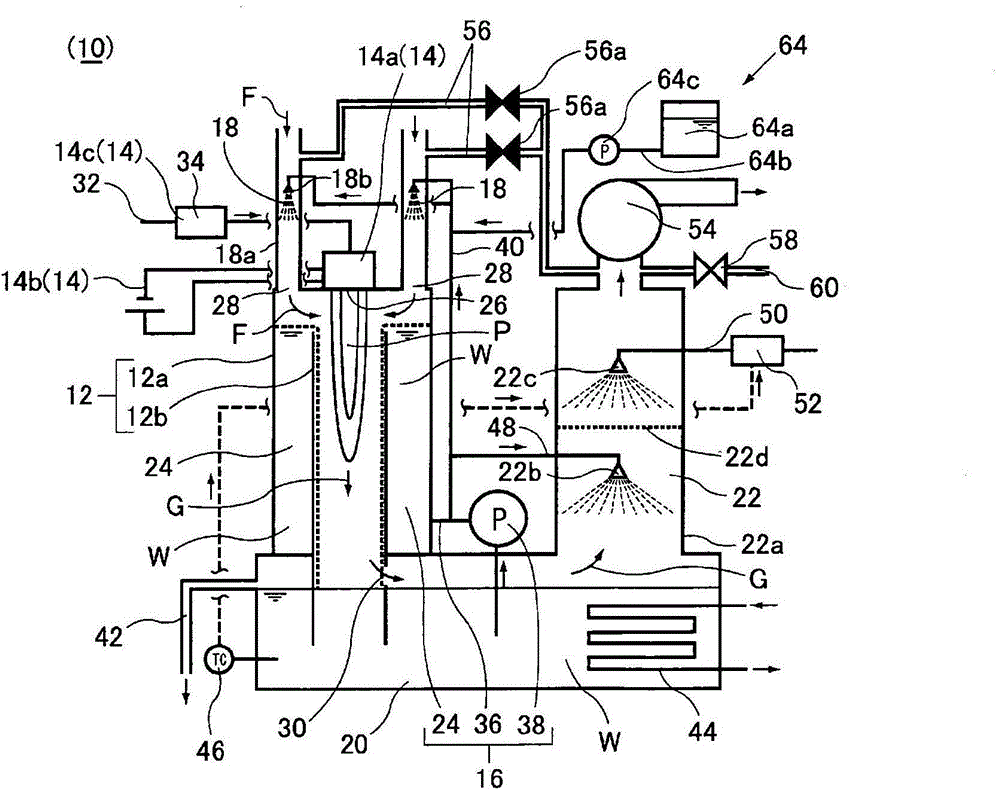

[0075] Next, the present invention will be described based on the illustrated embodiments. figure 1 It is a structural diagram showing the outline of the gas processing apparatus 10 of this embodiment. As shown in the figure, the gas treatment device 10 of this embodiment is roughly composed of a reactor 12, a plasma generator 14, a water supply device 16, a front wet scrubber 18, a water tank 20, a rear wet scrubber 22, and the like.

[0076] The reactor 12 is a device for thermally decomposing the gas F to be treated inside the atmospheric pressure plasma P generated by the plasma generator 14 described later and the gas F to be treated. Tube 12a and cylindrical inner tube 12b constitute a double-layer tube; the outer tube 12a is closed at both ends, and is erected on the water tank 20; Both ends are open, and at the same time, one axial end (upper end) is arranged to form a gap with the upper end surface of the outer cylinder 12a, and the other axial end (lower end) penetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com