Cyclone separator provided with double inlets and double outlets

A technology of cyclone separator and double outlets, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed. In order to improve the separation efficiency, the internal air flow field is uniform and symmetrical, and the longitudinal vortex flow is weakened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

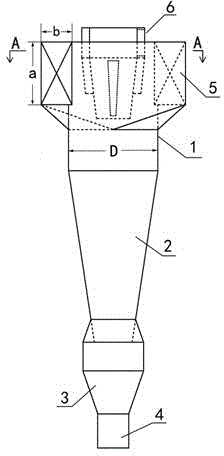

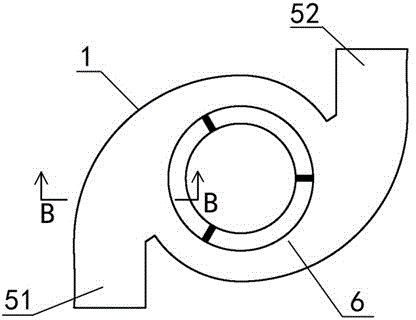

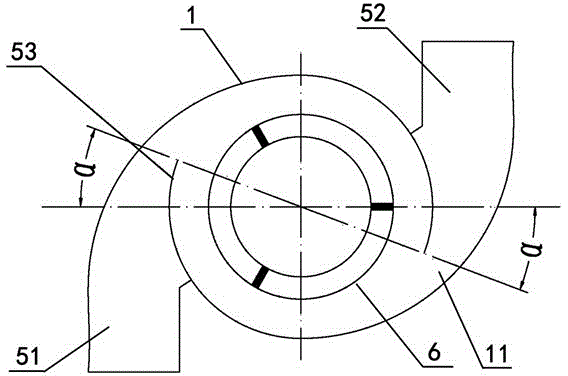

[0025] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6As shown, this embodiment has a cyclone separator with double inlets and double outlets, including a cyclone body 1, the lower end of the cyclone body 1 is provided with a cone 2, an intermediate ash hopper 3 and a sewage outlet 4 in turn, and the cyclone body 1 The upper end is provided with an air intake assembly 5 and an exhaust assembly 6, and the air intake assembly 5 includes a left air inlet 51 and a right air inlet 52 respectively arranged on the cyclone cylinder 1, and a left air inlet 51 and a right air inlet 52 They are respectively arranged along the tangential direction of the cyclone body 1 and both of them are symmetrically arranged relative to the axis of the cyclone body 1. The arc deflector 53, the air intake of the left air inlet 51 and the right air inlet 52 enters the inside of the cyclone cylinder body 1 after the arc deflector 53 deflects the flow respectively, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com