S-shaped stamping die capable of realizing uniform water cooling and partitioned cooling

A technology of zone cooling and stamping die, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing manufacturing cost and reducing production efficiency, and achieve the effect of improving production efficiency, simple structure and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

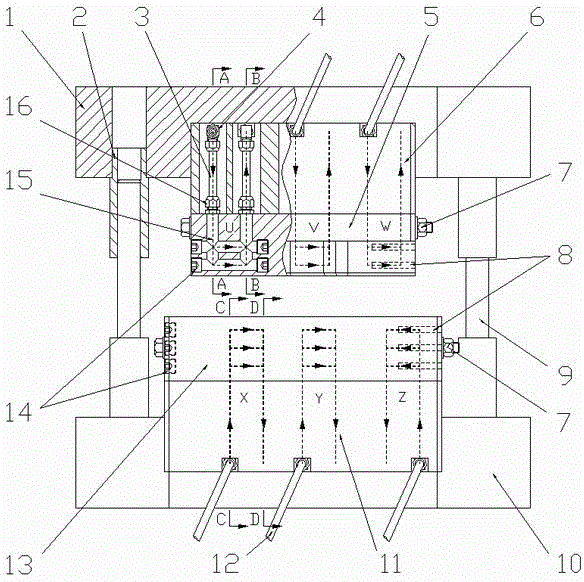

[0029] Figure 8 A schematic diagram showing uniform water cooling of the mold is shown. The first cooling water circuit U, the second cooling water circuit V, the third cooling water circuit W, the fourth cooling water circuit X, the fifth cooling water circuit Y and the sixth cooling water circuit Z all pass water, which will heat to Austenitic The boron steel plate in the solidified state is quickly transferred to the mold for stamping. Under the condition of ensuring a certain pressure, through the cooling effect of the water flow in the cooling water channel 15, each area of the plate can be cooled in the mold at the same cooling rate> 27 ℃ / s for quenching treatment, and after a period of holding pressure quenching, ultra-high-strength steel parts with uniform martensitic structure are obtained.

Embodiment 2

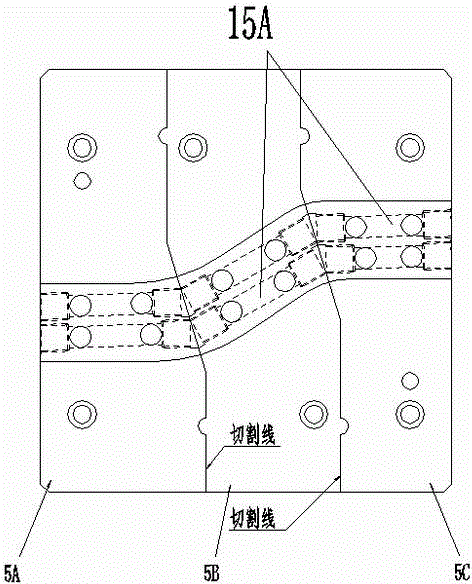

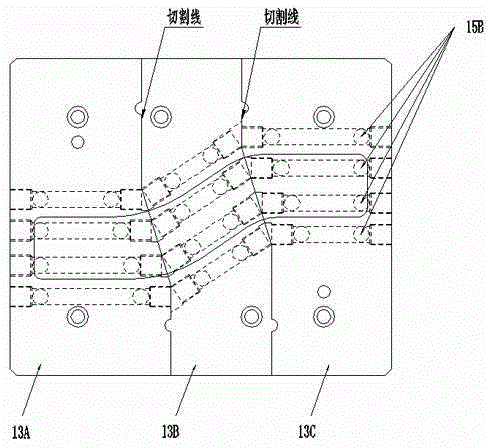

[0031] Figure 9A schematic diagram showing zoned cooling of the mold is shown. The first cooling water circuit U, the second cooling water circuit V, the fourth cooling water circuit X and the fifth cooling water circuit Y all pass water to cool the punch I5A, punch II5B, die I13A, and die II13B Function, the third cooling water circuit W and the sixth cooling water circuit Z are not connected to water, remove the plug 14 at the right end of the cooling water channel 15 in the punch III5C and the concave mold III13C, and the cooling water channel in the punch III5C and the concave mold III13C Insert the heating rod 8 in 15, and by controlling the temperature of the heating rod 8, the punch III5C and the die III13C are heated to a certain temperature higher than the punch I5A, the punch II5B, the die I13A, and the die II13B. The boron steel plate in the tempered state is quickly transferred to the mold for stamping. Under the condition of ensuring a certain pressure, each are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com