Automatic fastening disassembling module for fastening robot

A robot and fastening technology, applied in the direction of manipulator, metal processing, metal processing equipment, etc., to achieve the effect of comprehensive functions, high degree of automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

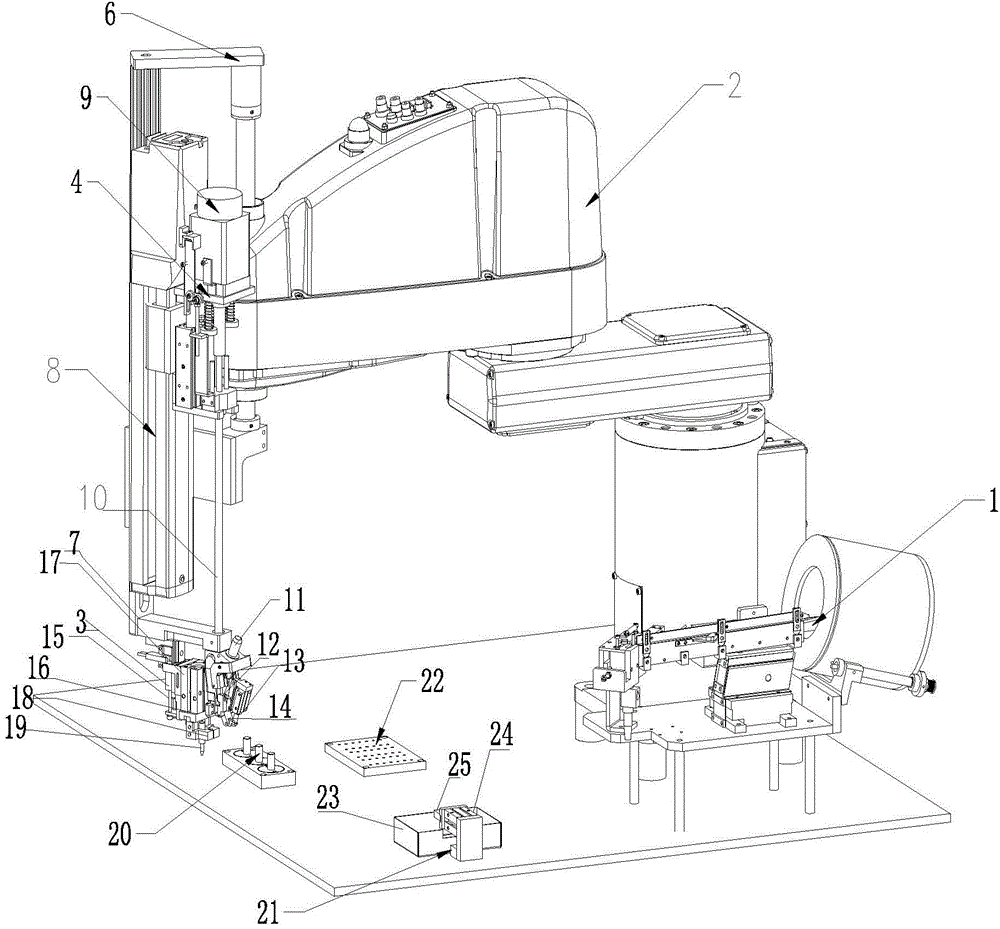

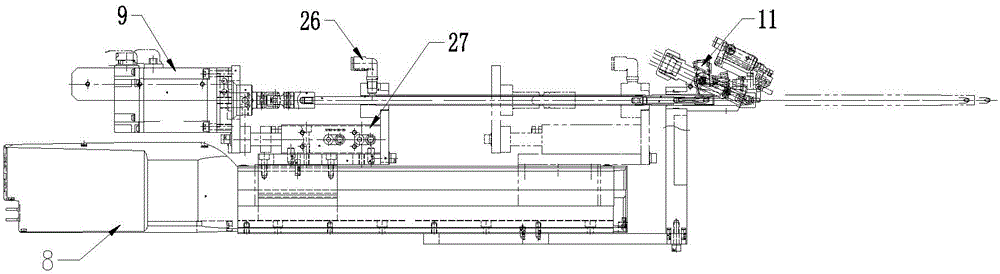

[0020] The embodiment of the present invention is as follows:

[0021] An automatic fastening and disassembly module of a fastening robot. The following is an embodiment of a fastening and disassembly robot that automatically picks and places workpieces to which it is specifically applied.

[0022] The robot includes a fastener array device 1, an automatic feeding mechanism;

[0023] The fastener array device 1 includes a rolling barrel. The rolling barrel is driven by a micro-motor provided at the bottom of the rolling barrel. The outlet of the rolling barrel is connected to a guide rail. The fasteners roll in the storage rolling barrel and enter by gravity. The directional sorting structure and the impurity removal groove at the head end of the guide rail, the linear section of the guide rail is provided with a piezoelectric linear vibration unit, a photoelectric sensor, and the end of the guide rail is provided with a separation device; the high-frequency vibration of the piezoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com