Flapping-wing aircraft with eccentric wheels for pushing and pulling sliding boxes to do reciprocating linear motion to enable wing membranes to float

A technology of reciprocating linear motion and flapping-wing aircraft, which is applied in the field of flying wing-film flapping-wing aircraft, can solve the problems of low energy efficiency ratio, large energy consumption, clumsiness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

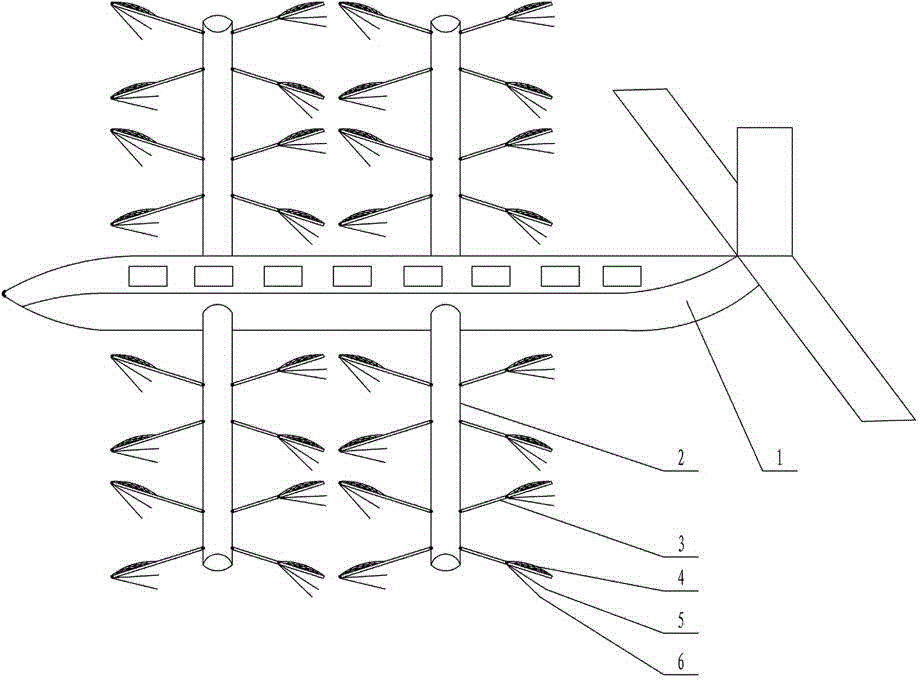

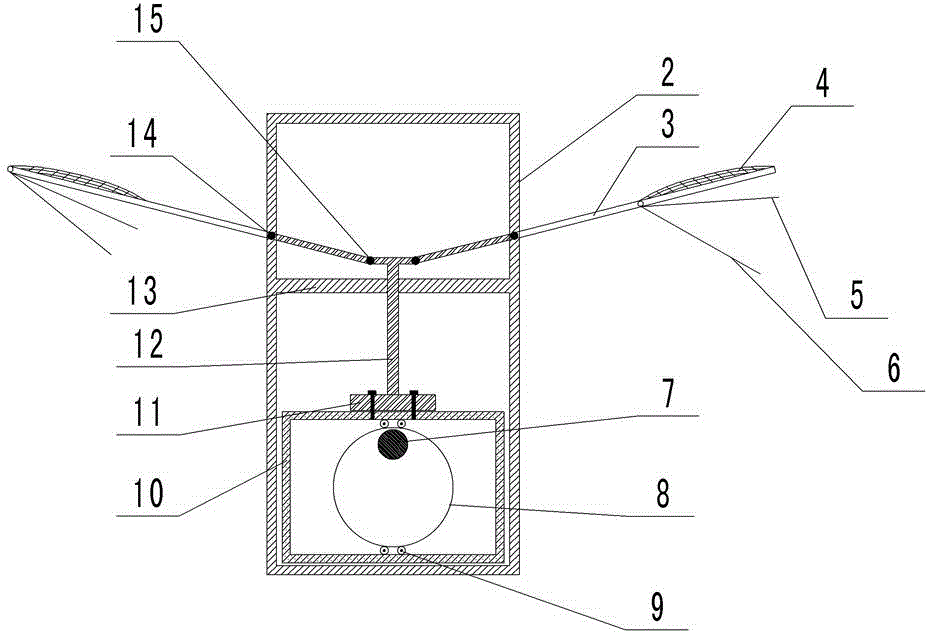

[0017] Such as figure 1 Shown is a schematic structural diagram of an eccentric wheel push-pull sliding frame for reciprocating linear motion and a flapping wing aircraft with an elegant membrane, including a fuselage 1, and several rotatable tilting wing trunk arms 2 are symmetrically arranged on both sides of the fuselage 1 . Such as figure 2 Shown is a pair of flapping wing jibs 3 and a schematic diagram of the transmission connection structure of the main arm of the tilting wing. The two sides of the tilting wing trunk arm 2 are symmetrically provided with several flapping wing jibs 3, and the engine power device in the fuselage 1 is transmitted to the flapper for reciprocating up and down directions through the main transmission shaft 7 in the tilting wing trunk arm 2. Wing jib frame 3, a part of flapping wing jib frame 3 passes through the main arm 2 of the tilting wing and is exposed to the outside. A plurality of eccentric wheels 8 are vertically connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com