Nitrogen slurry preparation device and method combined with throttle valve and expander

A preparation device and expanding tube technology, applied in chemical instruments and methods, nitrogen compounds, refrigeration and liquefaction, etc., can solve the problems of low production efficiency and high requirements for cryogenic heat exchangers, and achieve low manufacturing costs, no moving parts, non-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

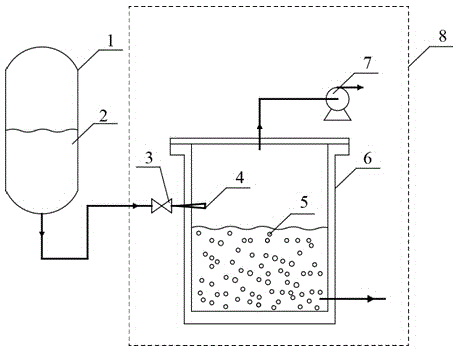

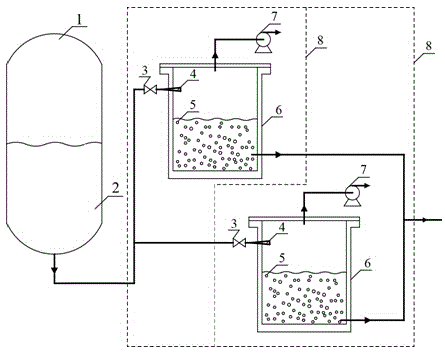

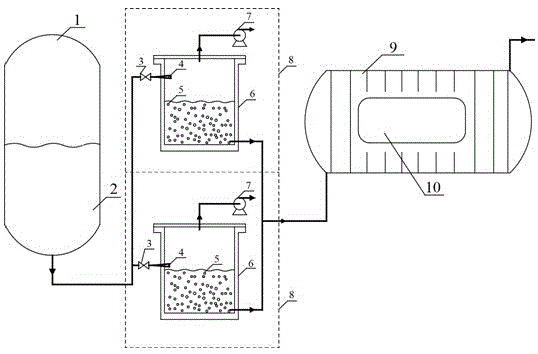

[0015] Such as Figure 1-3 As shown, the nitrogen slurry preparation device combined with the throttle valve and the expander includes a liquid nitrogen storage tank 1, a nitrogen slurry preparation unit 8, and the nitrogen slurry preparation unit includes a throttle valve 3, an expander 4, an adiabatic Dewar 6, and a vacuum pump 7; liquid nitrogen storage tank 1, throttle valve 3, gradual expansion pipe 4, and adiabatic dewar 6 are connected in sequence, and adiabatic dewar 6 is connected with vacuum pump 7; liquid nitrogen storage tank 1 contains liquid nitrogen 2, and adiabatic dewar Receive and store the nitrogen slurry 5 within 6.

[0016] There may be more than two nitrogen slurry preparation units 8 connected in parallel. The bottom of the adiabatic Dewar 6 is connected to a cooling heat sink 9, and an object to be cooled 10 is arranged in the cooling heat sink 9. The prepared nitrogen slurry can be transported from the adiabatic Dewar 6 to the cooling heat sink 9 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com