Carbon fiber surface defect repairing method

A carbon fiber and defect technology, applied in the field of carbon fiber manufacturing process improvement, can solve the problems of carbon fiber mechanical performance index decline, not very good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

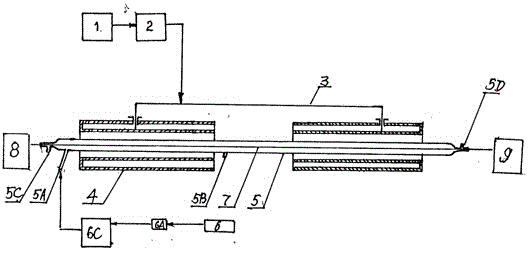

[0008] as attached figure 1 As shown, the specific embodiment of the present invention mainly includes the following steps: the carbon fiber 7 that will be surface treated passes through the quartz tube reactor 5 and is arranged between the sending and receiving wire mechanisms 8, 9, and the carbon fiber 7 is heated by a strong focused electromagnetic field induction. To 1000-1300°C, at this time, the argon gas filled between the gas charging ports 5C and 5D ensures that external oxygen cannot enter the reactor 5, and 0.9-1.2 liters of acetylene gas per hour is directed against the carbon fiber at the gas charging port 5A. The moving direction enters the quartz reactor 5, and contacts with the carbon fiber at high temperature to generate a cracking reaction, and the free carbon atoms generated by the reaction are deposited on the surface and the cavity of the carbon fiber. The linear speed of the carbon fiber 7 in the quartz reactor is 2-3 m / min, which can effectively ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com