Sinking pipe soil withdrawing and cast-in-place rectangular supporting pile diaphragm wall and construction method thereof

A technology of supporting piles and ground-connecting walls, applied in the field of building foundation engineering, can solve the problems of good effect and high engineering cost, and achieve the effects of no mud pollution, reduced engineering cost and simple construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

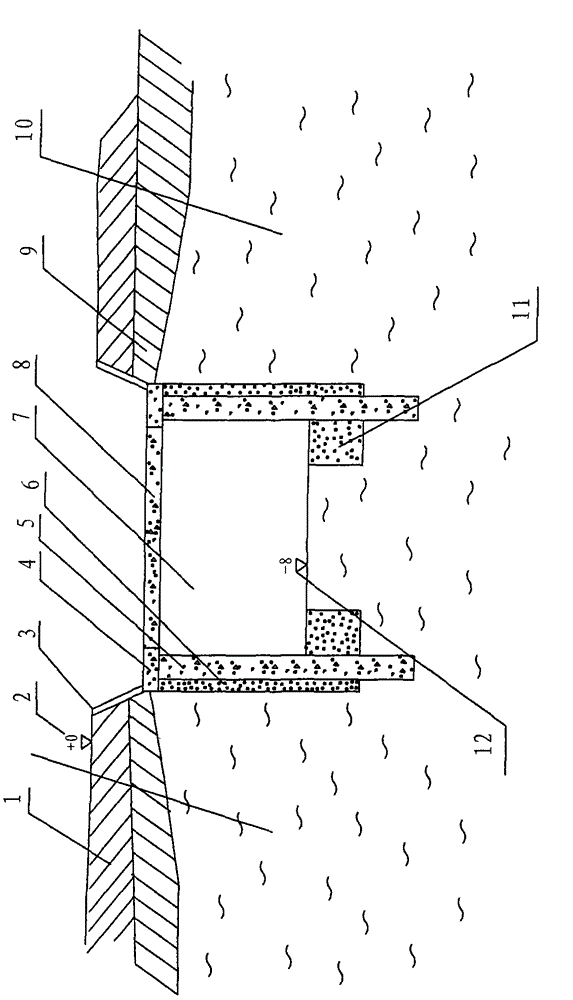

[0018] A typical embodiment of the present invention is figure 1 , and its construction process is as follows:

[0019] (1) Leveling the site, constructing 2 rows of mutually overlapping cement mixing piles (6) water-stop curtain and cement mixing pile pier (11) inside the foundation pit on the outside of the foundation pit;

[0020] (2) Vibrating the double-layer steel immersed tubes (the distance between the two tubes is 5-15mm) into the ground to the design elevation by vibrating the vibrating hammer on the column of the immersed tube pile machine. Then, the inner tube is raised and the soil in the inner tube is released.

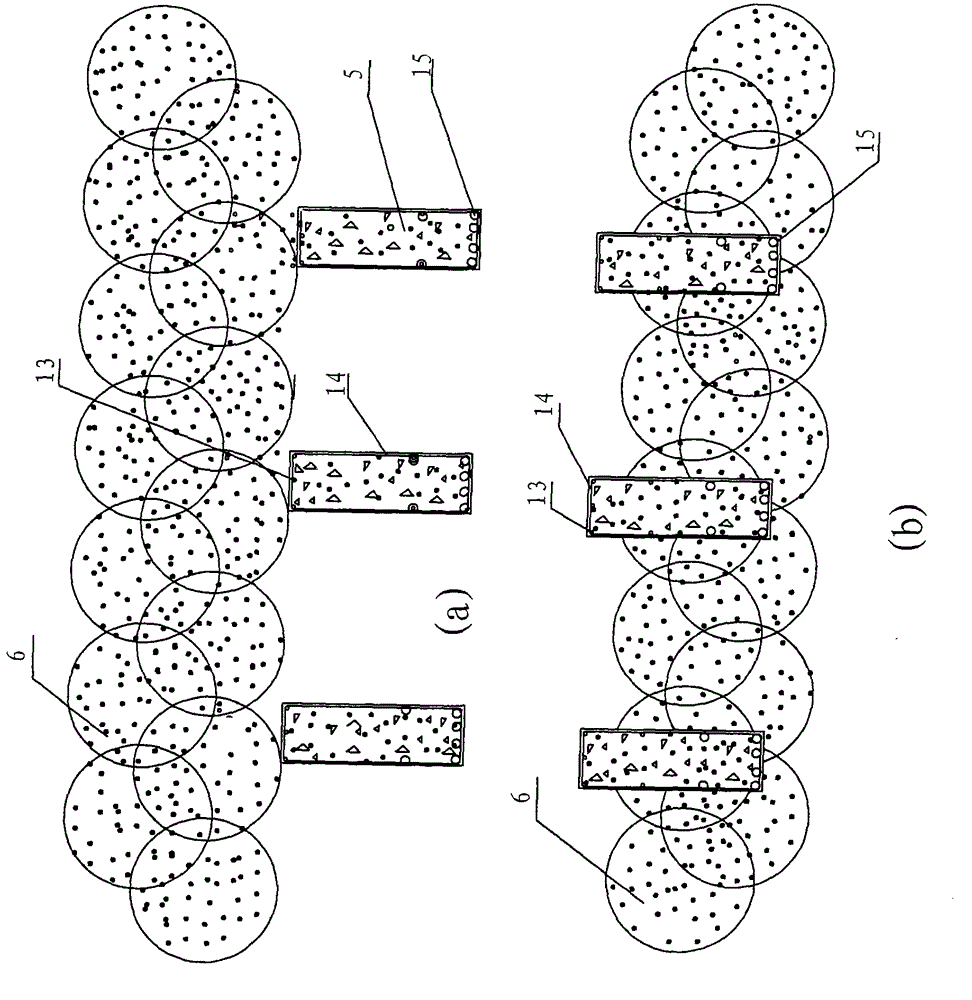

[0021] (3) Place a rectangular reinforcement cage made of thick steel bars (13), thin steel bars (15) and stirrups (14) into the cavity of the outer tube, then pour concrete into the tube to make a rectangular support pile (2) ;

[0022] (4) The outer steel immersed tube is vibrated and pulled up and recovered by the vibrating hammer on the column of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com