Method for measuring 3-acetyl-2, 5-dimethyl thiophene in edible flavor and fragrance

A technology of dimethyl thiophene and food flavor, applied in the direction of measuring devices, material separation, and analysis of materials, can solve safety problems, lack of research and other problems, and achieve the effects of short time consumption, good repeatability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

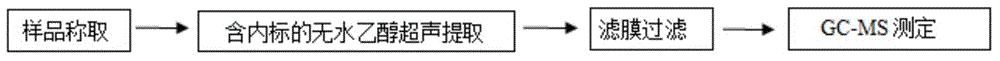

Method used

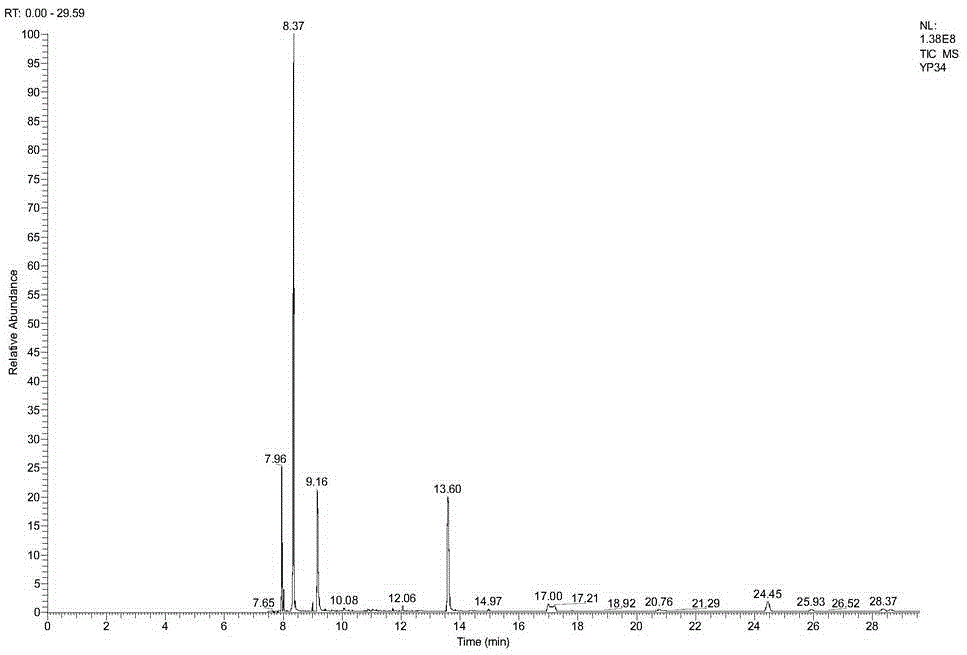

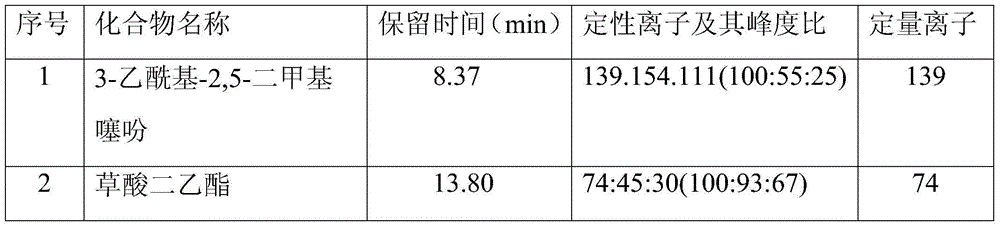

Image

Examples

Embodiment 1

[0024] 1. Instruments and reagents

[0025] Gas chromatography-mass spectrometry (Thermo TRACE 1300) chromatographic column (Thermo TG-WAXMS, 30m×0.25mm×0.25μm), Millipore Q-pod Element ultrapure water system (Millipore, USA); AB204-S electronic analysis Balance (sensitivity 0.0001g) (Mettler, Switzerland), 0.22 μm microporous filter membrane, ultrasonic cleaner.

[0026] Ultrapure water (18MΩ), ethanol (chromatographically pure, Bailingwei Chemical Reagent Company), 250pmoL / μL, Agilent).

[0027] 2. Solution preparation

[0028] (1) Internal standard solution preparation

[0029] Internal standard stock solution: Accurately weigh 0.0365g (accurate to 0.0001g) of diethyl oxalate in a 50mL volumetric flask, dissolve with absolute ethanol and constant volume to obtain 0.73g / L internal standard mother solution. Store in a cool, dry place to prevent moisture.

[0030] Internal standard extract: pipette 1mL of internal standard stock solution into a 1000mL volumetric flask, dil...

Embodiment 2

[0040] The present embodiment detects the standard addition recovery rate of the present invention, and analysis method is as follows:

[0041] Taking the sample containing 3-acetyl-2,5-dimethylthiophene detected in Example 1 as the object, referring to the method of Example 1, using the method of adding standard at three levels of low, medium and high, adding 3 -Acetyl-2,5-dimethylthiophene standard sample, measure its content after adding standard. Each level was measured in parallel three times, and the average value was taken to calculate the recovery rate of the standard addition. The measurement results are shown in Table 1:

[0042] Table 1 Method spike recovery

[0043]

[0044] It can be seen from Table 1 that the recovery rate of the standard addition of the sample is between 95.91-100.23%, indicating that the recovery rate of this method is better.

Embodiment 3

[0046] The present embodiment detects the precision of the present invention, and analysis method is as follows:

[0047] Taking the sample containing 3-acetyl-2,5-dimethylthiophene detected in Example 1 as the object, referring to the method of Example 1, 6 parallel determinations of 3-acetyl-2,5-dimethylthiophene in the spiked sample The content of dimethylthiophene, calculate relative standard deviation, investigate the precision of method, the result is as shown in table 2,

[0048] The precision of the method in Table 2

[0049]

[0050]It can be seen from Table 2 that the relative standard deviation RSD of this method is less than 3%, indicating that the method has good repeatability and meets the experimental requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com