Machining workshop scheduling and monitoring system and method

A technology of workshop scheduling and machining, applied in the field of automation, can solve problems such as processing time change, lack of on-site information collection, affecting production progress, etc., to reduce impact and loss, achieve scheduling results, and be suitable for popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

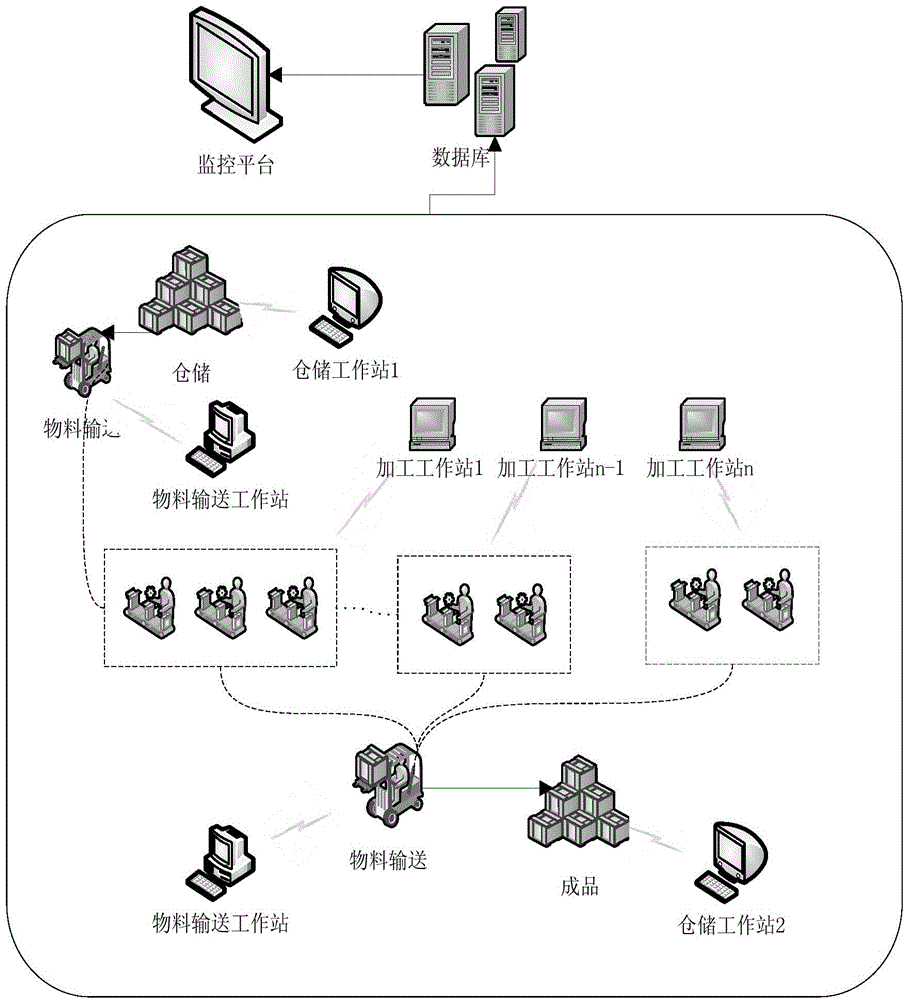

[0036] (1) Production scheduling and monitoring platform, including scheduling, monitoring, and display modules, of which:

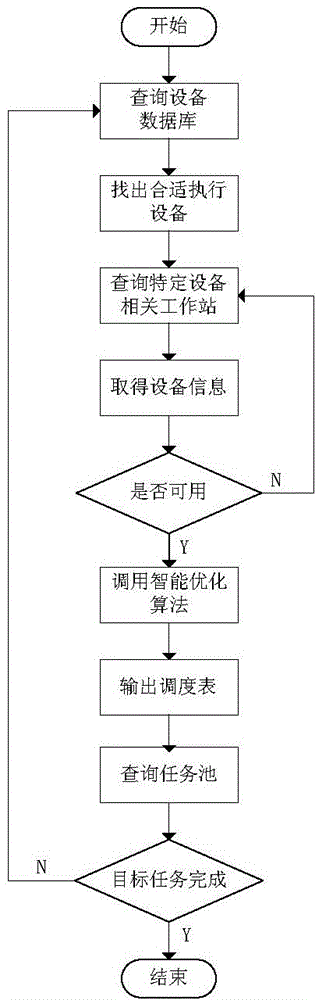

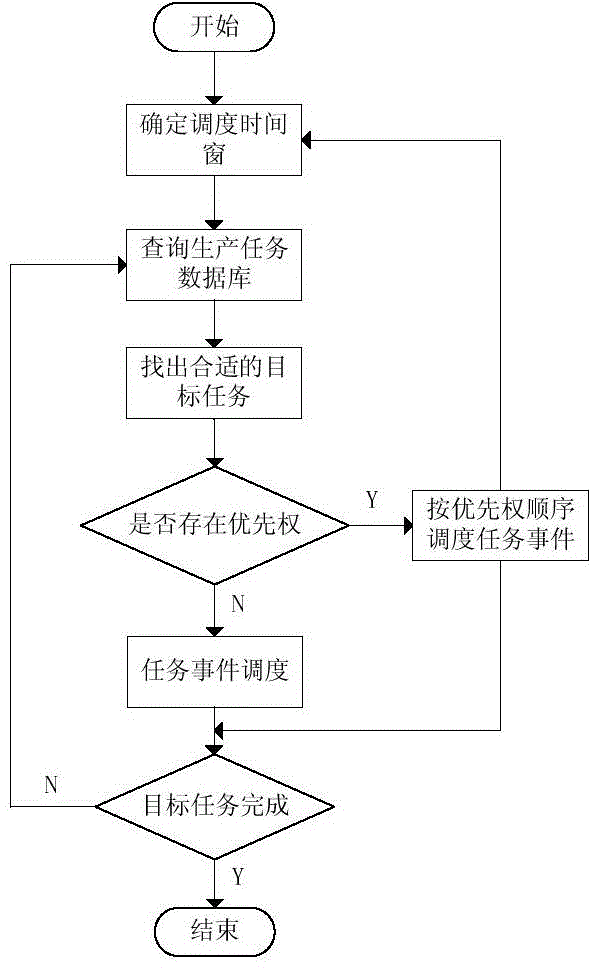

[0037] 1) The scheduling module invokes the optimal scheduling algorithm through the scheduler. According to the production tasks issued by the production planning system and the real-time data of the production site provided by the monitoring module, the scheduling decision is obtained through the intelligent scheduling optimization algorithm, and the "task- Machine-time" production schedule, and send the result to the display and monitoring module;

[0038] 2) The monitoring module also has the function of supervising and controlling the production site, focusing on the monitoring of the order manufacturing process and tracking of work in progress;

[0039] Use the wireless sensor network to obtain the production site data from each workstation, and obtain the completion status of each processing task and the status information of related materials throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com