Lithium-carbon-boron oxide solid electrolyte material containing plane triangle group and battery

A solid electrolyte, triangular-based technology, applied in the field of materials, to achieve low electronic conductivity and solve safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

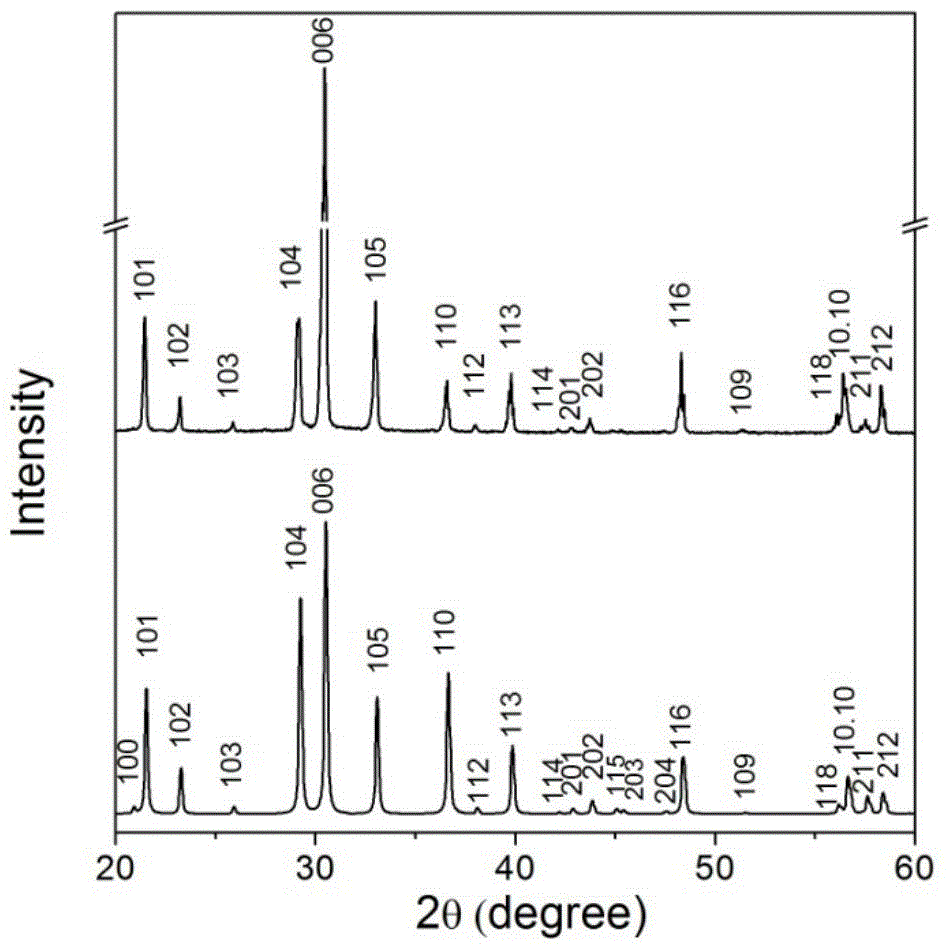

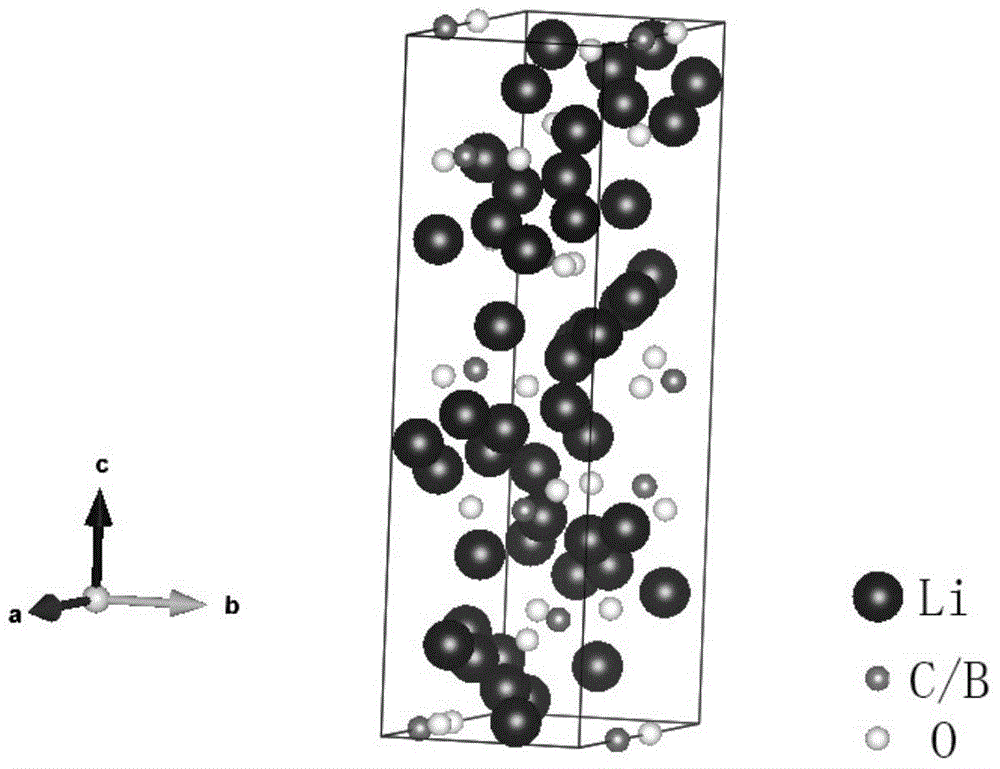

[0048] Embodiment 1 of the present invention provides a lithium carbon boron oxide solid electrolyte material containing a planar triangular group, and its general chemical formula is: Li 2+x C z B b m m o 3-n Y n ;

[0049] Among them, C refers to carbon element, B refers to boron element, and O refers to oxygen element; each C or B or M forms a plane triangular structure with adjacent three Os, or each C or B or M forms a planar triangular structure with adjacent three Two Ys form a planar triangular structure; M is an element for doping and substituting Li, C or B; Y is an element for doping and substituting O; the M is specifically Na, K, Mg, Ca, Al, Ga , one or more of La, Y, Si,, Ge, Zr; said Y is specifically one or more of S, N, F; said x, z, b, m, n are respectively The mole percentage of the corresponding element; 0≤x≤1, 0.3≤z≤1, 0≤b≤1, 0≤m≤0.2, 0≤n≤0.5;

[0050] The lithium carbon boron oxide solid electrolyte material containing planar triangular groups prov...

Embodiment 2

[0059] This embodiment provides a preparation method of a lithium carbon boron oxide solid electrolyte material containing a planar triangular group, specifically a preparation method of a powder material, such as Image 6 shown, including:

[0060] Step 201, Li source, C source, B source, M source, Y source according to Li 2+x C z B b m m o 3-n Y n molar ratio ingredients to form a precursor;

[0061] Specifically, the M can be one or more of Na, K, Mg, Ca, Al, Ga, La, Y, Si, Ge, Zr; the Y can be S, N, F One or more; said x, z, b, m, n are the mole percentages of corresponding elements; 0≤x≤1, 0.3≤z≤1, 0≤b≤1, 0≤m≤0.2 , 0≤n≤0.5.

[0062] Step 202, mixing uniformly through hand milling, planetary ball milling or high-energy ball milling to obtain precursor powder;

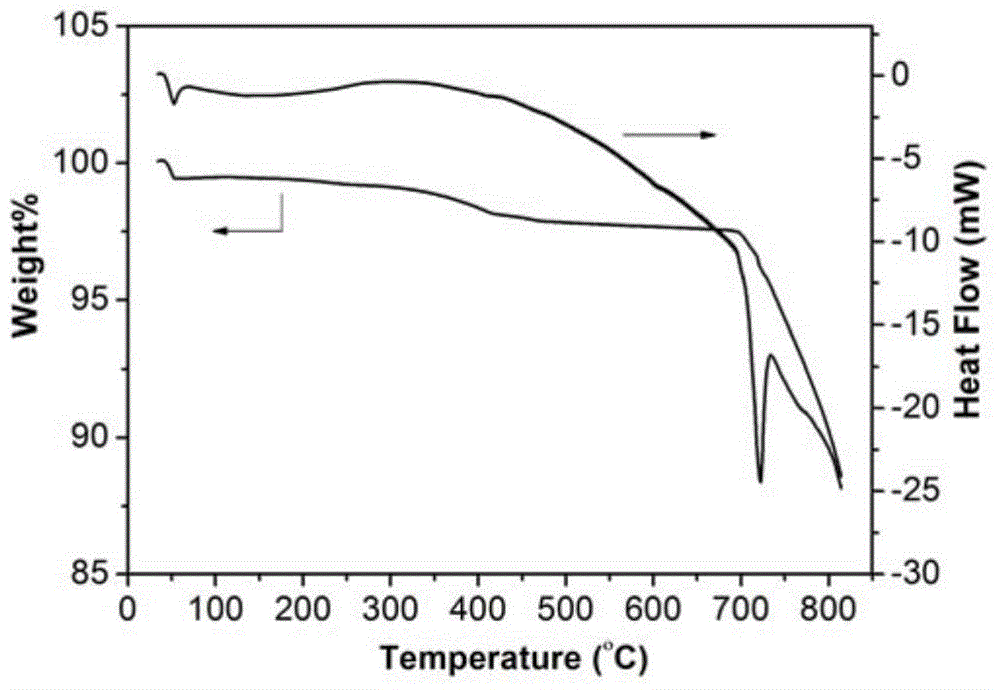

[0063] Step 203, pretreating the precursor powder in an air atmosphere at 100° C. to 500° C. for 1 to 12 hours;

[0064] Step 204, performing hand grinding, planetary ball milling or high energy ball milli...

Embodiment 3

[0068] This embodiment provides a preparation method of a lithium carbon boron oxide solid electrolyte material containing a planar triangular group, specifically another preparation method of a powder material, such as Figure 7 shown, including:

[0069] Step 301, Li source, C source, B source, M source, Y source according to Li 2+x C z B b m m o 3-n Y n molar ratio ingredients to form a precursor;

[0070] Specifically, the M can be one or more of Na, K, Mg, Ca, Al, Ga, La, Y, Si, Ge, Zr; the Y can be S, N, F One or more; said x, z, b, m, n are the mole percentages of corresponding elements; 0≤x≤1, 0.3≤z≤1, 0≤b≤1, 0≤m≤0.2 , 0≤n≤0.5.

[0071] Step 302, mixing uniformly through hand milling, planetary ball milling or high-energy ball milling to obtain precursor powder;

[0072] Step 303, pretreating the precursor powder in an air atmosphere at 100° C. to 500° C. for 1 to 12 hours;

[0073] Step 304, performing hand grinding, planetary ball milling or high energy bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com