A kind of negative electrode polymer protective coating of lithium ion battery and its preparation method and application

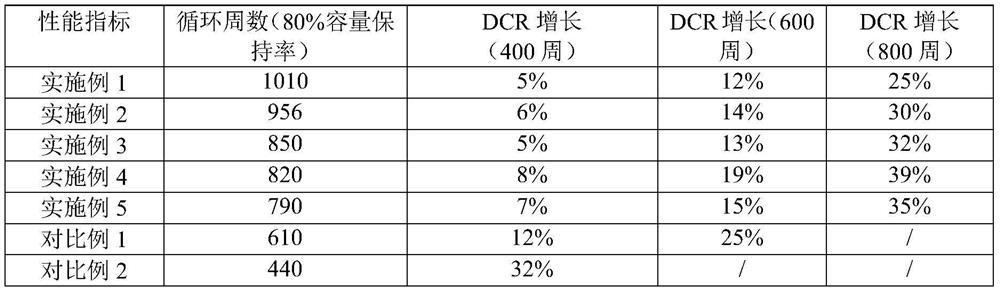

A lithium-ion battery, protective coating technology, applied in electrode current collector coating, electrode manufacturing, battery electrodes and other directions, can solve the problems of battery capacity decay, consumption of lithium ions, easy damage of negative electrode SEI layer, etc., to reduce damage , easy industrialization, excellent electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

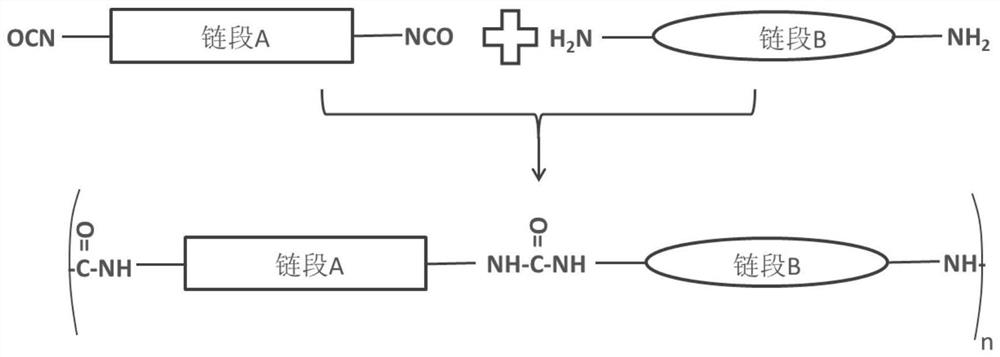

[0042] (1) According to figure 1 For the polymer synthesis mechanism shown, MDI (4,4'-methylene diphenyl diisocyanate) (20 mmol) and PTMG (polytetrahydrofuran, Mw=2900 ) (10mmol), heated at 80°C for 4h under the protection of an inert argon atmosphere to form an isocyanate-terminated PTMG intermediate;

[0043] (2) After cooling to room temperature, add EDA (ethylenediamine) (8mmol) into the solution under vigorous stirring, heat the mixture to 70°C and react for 4h, and then mix in a certain amount of PEI (polyethyleneimine) , mixed evenly for 2h. Finally, the polymer solution was poured into a polytetrafluoroethylene mold, and the solvent was evaporated at 60° C. to obtain a lithium-ion battery negative electrode polymer protective coating with a thickness of 500 μm.

[0044] Electrolyte swelling degree: Cut the above lithium-ion battery anode polymer protective coating into blocks, and accurately weigh its mass w 0 . The film was transferred to an electrolyte solution (...

Embodiment 2

[0051] (1) With reference to Example 1, polyethylene glycol containing terminal isocyanate is prepared, and then polyethylene glycol (segment A) and polyphenylenediamine (segment B) containing terminal isocyanate are combined according to the ratio of isocyanate and active amino group After the molar ratio of the groups is 1:1, the condensation reaction occurs at 55°C to obtain the polymer;

[0052] (2) Dissolving the polymer in N-methylpyrrolidone to prepare a polymer solution with a concentration of 5w%;

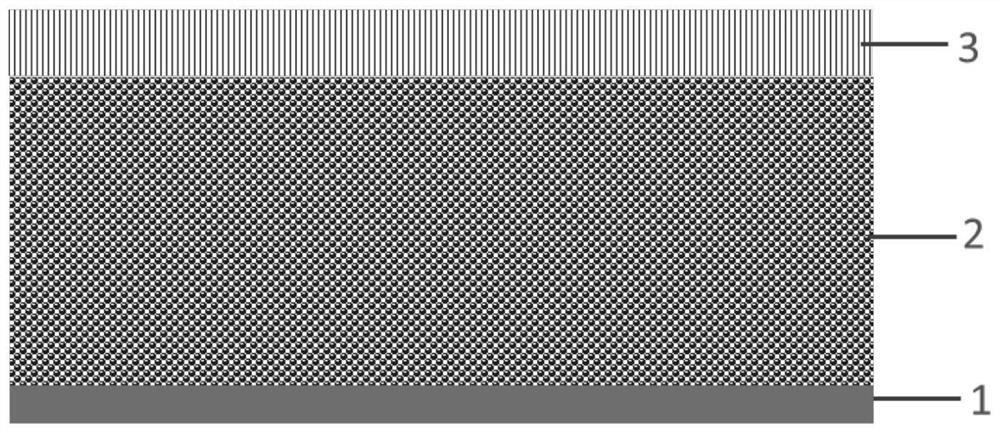

[0053] (3) Prepare lithium-ion battery negative electrode slurry, apply it on the copper foil substrate to obtain electrode sheet E1, and roll it once to obtain a porosity of 25% and a compacted density of 1.50 g cm -3 The electrode sheet E2;

[0054] (4) The polymer solution obtained in step (2) is coated on the electrode sheet E2 through an extrusion coating machine, and after drying, it is rolled twice to obtain a compacted density of 1.65 g cm -3 The electrode sheet ...

Embodiment 3

[0057] (1) Referring to Example 1, the polypropylene glycol containing terminal isocyanate is prepared, and then the polypropylene glycol (segment A) containing terminal isocyanate and polyethyleneimine-polyphenylenediamine front-end copolymer (segment B) are prepared according to the isocyanate After mixing with active amino groups at a molar ratio of 1:1.05, a condensation reaction occurs at 40°C to obtain a polymer;

[0058] (2) dissolving the polymer in N,N-dimethylacetamide to prepare a polymer solution with a concentration of 10w%;

[0059] (3) Prepare lithium-ion battery negative electrode slurry, apply it on the copper foil substrate to obtain electrode sheet E1, and roll it once to obtain a porosity of 25% and a compacted density of 1.40 g cm -3 The electrode sheet E2;

[0060] (4) Transfer and coat the polymer solution obtained in step (2) onto the electrode sheet E2, after drying, roll it twice to obtain a compacted density of 1.55 g cm -3 The electrode sheet E3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com