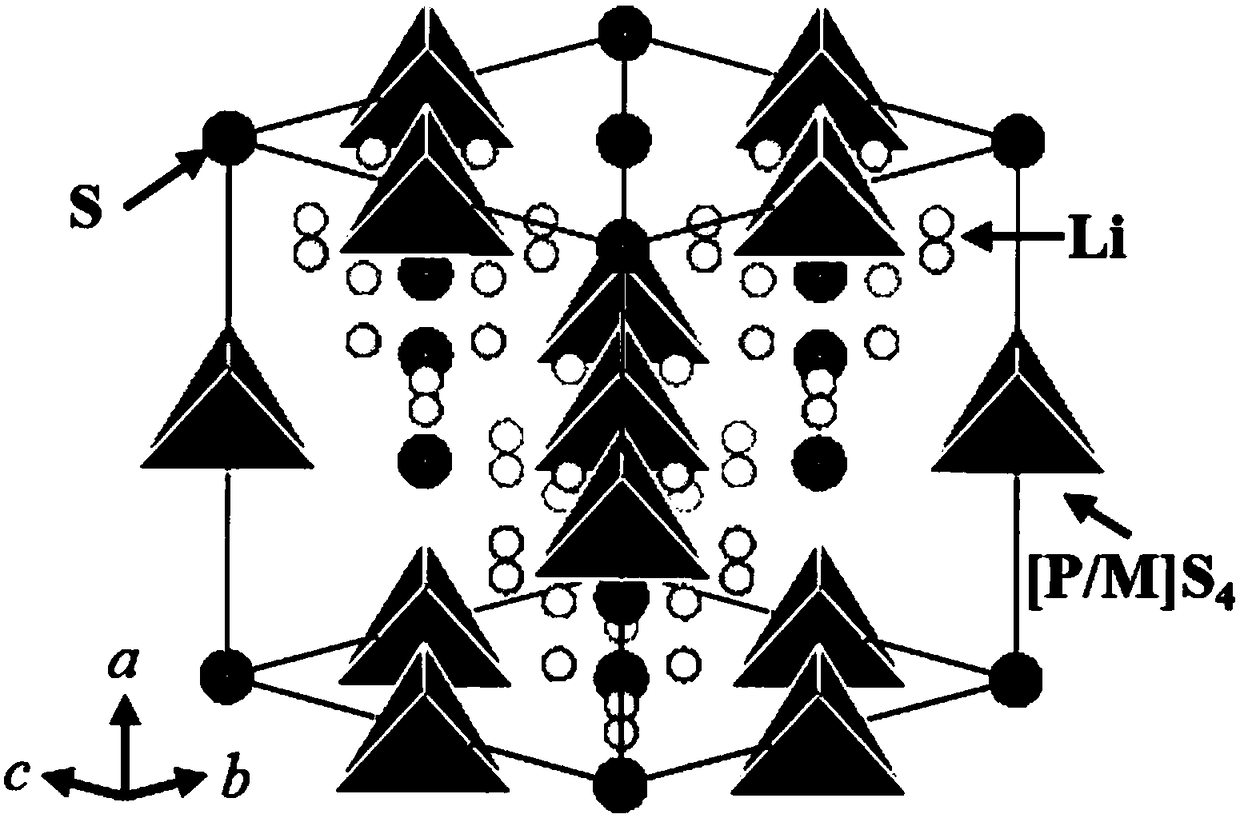

Cubic-phase sulfide and preparation method thereof

A sulfide, cubic phase technology, applied in chemical instruments and methods, lithium compounds, aluminum compounds, etc., can solve problems such as hindering preparation and use, and achieve the effect of saving production costs and simplifying preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

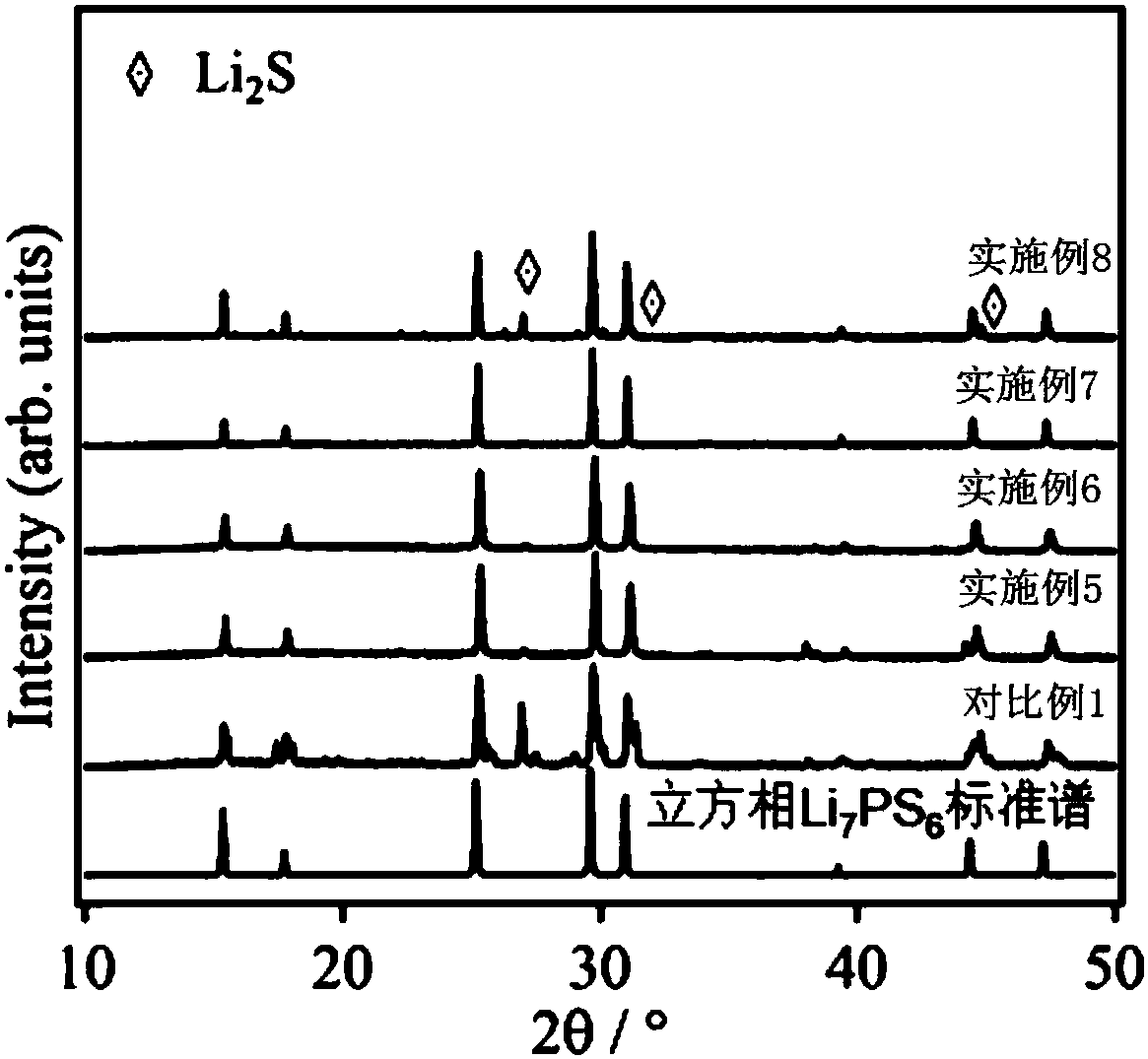

Examples

preparation example Construction

[0034] The preparation method of above-mentioned cubic phase sulfide is: Li 2 S, M 2 S a ,P 2 S 5 Weigh under an inert atmosphere with a molar ratio of y:x:(1-x), and mix them evenly, and carry out solid-phase synthesis of raw materials under anaerobic conditions at 400°C to 650°C for 8h to 18h, so as to prevent reactants from being mixed with air Oxygen or moisture in the reaction to generate impurities, until complete reaction to generate Li y m x P 1-x S 6 ; The oxygen-free condition can be a vacuum less than 100Pa, or an inert gas such as nitrogen or argon.

[0035] And in the raw material Li 2 S-M 2 S a -P 2 S 5 There are crystal phases with various structures in the system, uniform mixing is very important, uneven mixing will cause inconsistency of components, and impurities are likely to be generated; at the same time, the mixing process is also accompanied by the refinement process of raw materials, which is conducive to later vulcanization The synthesis of ...

Embodiment 1

[0037] In an argon-protected glove box, the Li 2 S, M 2 S a ,P 2 S 5 Weigh at the molar ratio of (7+5x-ax):x:(1-x), and mix them as raw materials; in this example, a is the valence of M, M is B, and x is 0.1;

[0038] Put the raw materials and zirconia balls into a zirconia-substrate ball mill tank with a capacity of 100, seal the container, perform ball mill mixing at a speed of 220 r / min, and obtain a mixed powder after 24 hours;

[0039] Put the mixed powder in the glove box, take it out, and form it under 150MPa pressure in a powder tablet press, put it into a glass / quartz tube, evacuate it until the vacuum degree is less than 100Pa, seal it, and put it into a muffle furnace. The temperature rise rate of the muffle furnace is 100°C / hour, and then the solid-state reaction is carried out at 400°C for 18 hours, and the temperature is naturally cooled to obtain the product Li (7+5x-ax) m x P 1-x S 6 , in this example, the product is Li 7.2 B 0.1 P 0.9 S 6 .

[004...

Embodiment 21

[0045] First, in an argon-protected glove box, the Li 2 S, B 2 S 3 、Al 2 S 3 ,P 2 S 5 Weigh with the molar ratio of 7.4:0.1:0.1:0.9, and mix as raw material;

[0046] Put the raw materials and zirconia balls into a zirconia-substrated ball mill tank with a capacity, seal the container, perform ball mill mixing at a speed of 300r / min, and obtain a mixed powder after 18 hours;

[0047] Put the mixed powder in the glove box, take it out, shape it under the powder tablet press, put it into a glass / quartz tube, evacuate it until the vacuum degree is less than 100Pa, seal it, and put it into a muffle furnace. The temperature rise rate of the muffle furnace is 100°C / hour, and then the solid-state reaction is carried out at 400°C for 18 hours, and the temperature is naturally cooled to obtain the product Li 7.4 B 0.1 Al 0.1 P 0.8 S 6 .

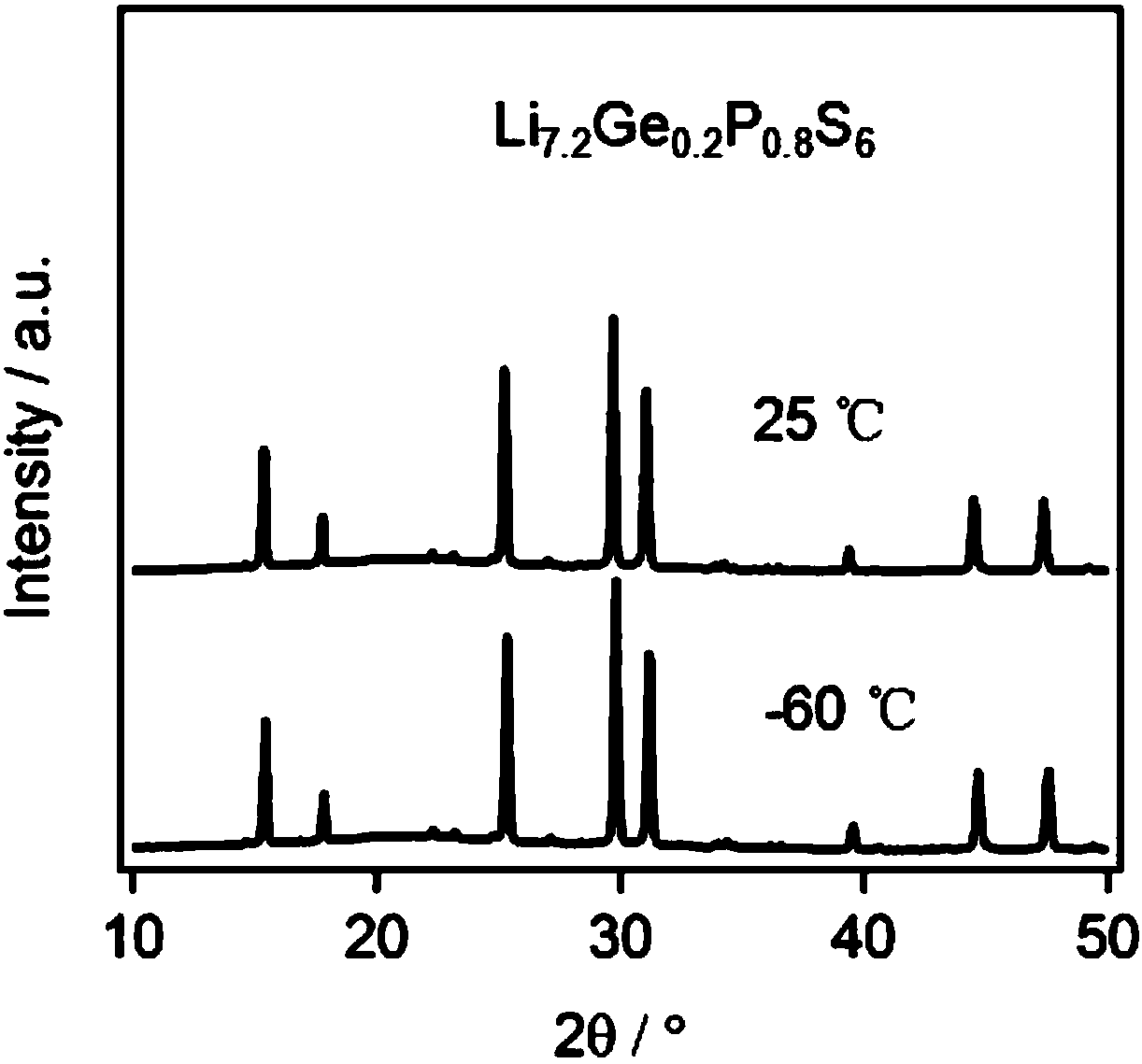

[0048] In the glove box, the product was taken out from the sealed glass tube, crushed and ground in a mortar, and a powder sample with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amplitude | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com