A kind of organic material and its preparation method, organic solid electrolyte and its preparation method and application

A technology of organic solids and organic materials, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problem of low energy density of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a kind of preparation method of organic material described in above-mentioned technical scheme, comprises the following steps:

[0042] Phosphorous substances, HO[CH 2 CH 2 O] x1 H. The substance with the structure of formula II is mixed with the metal-containing material, reacted, and the temperature is gradually raised until no fractions or by-products flow out, and purified to obtain an organic material;

[0043] The metal-containing material includes Li-containing material or Na-containing material; 1≤x1≤2000;

[0044] HO[CH 2 CH 2 O] x2 (C=O) y (CH 2 ) z CH 3 Formula II;

[0045] In formula II, 1≤x2≤100, y is 0 or 1, 0≤z≤10;

[0046] The phosphorus-containing substance, HO[CH 2 CH 2 O] x1 H. The molar ratio of the substance having the structure of formula II to the substance containing the metal is 1:a:b:c; wherein, 0≤a≤1.5, 0<b≤3, c=3-a-b.

[0047] In the present invention, the phosphorus-containing substance is prefe...

Embodiment 1

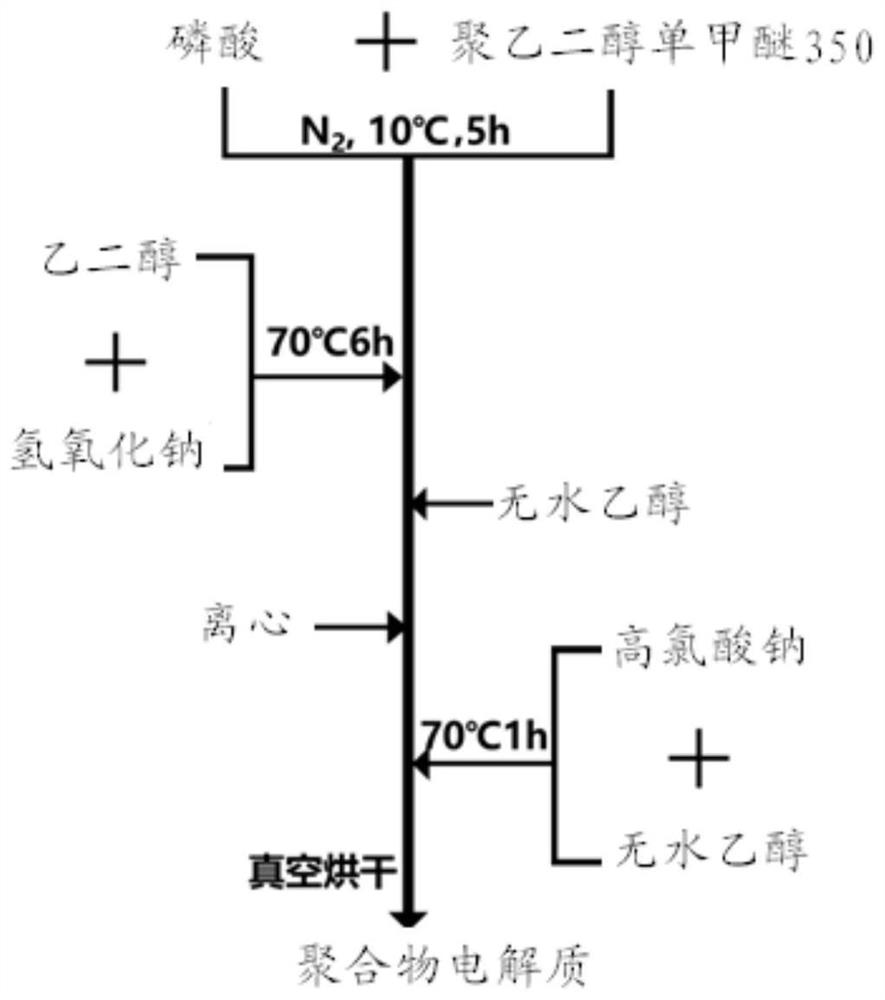

[0079] see figure 1 , figure 1 A schematic flow diagram for preparing an organic solid electrolyte for Example 1 of the present invention;

[0080] Under the protection of a nitrogen atmosphere, 9.8 g of phosphoric acid was added into 35 g of polyethylene glycol monomethyl ether (molecular weight: 350) which was continuously stirred, and reacted at 10° C. for 5 hours. Add 3.1 g of ethylene glycol and 4 g of sodium hydroxide, raise the temperature to 70° C., and react for 6 hours. After adding ethanol to fully dissolve, centrifuge at a speed of 5000 rpm for 15 min, and remove the white solid in the lower layer to obtain an organic solid with a purity of 85%. Add 3.51g NaClO 4 Continue stirring at 70°C for 1 hour; transfer to a vacuum oven, and dry at 120°C for 12 hours to obtain an organic solid electrolyte.

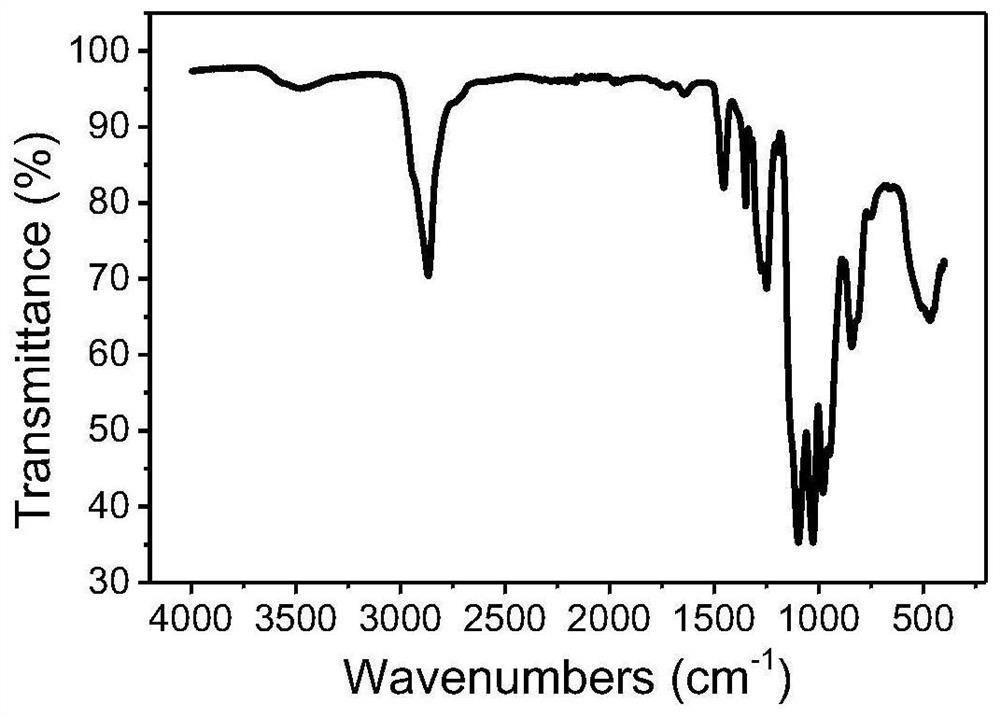

[0081] figure 2 The infrared spectrogram of the organic solid (before adding lithium salt) prepared for the embodiment of the present invention 1; From figure 2 I...

Embodiment 2

[0085] Under the protection of an argon atmosphere, 1.5 g of phosphorus pentoxide was dispersed in 20 g of cyclohexane, added to 90 g of polyethylene glycol monomethyl ether (molecular weight: 1000) under constant stirring, and reacted at -10°C for 3 hours. The temperature was raised to 80°C and reacted for 6 hours. An appropriate amount of water was added, and lithium hydroxide was added in batches at 50° C. to adjust the pH until pH=8. 10 g of water was added and distilled at 75° C. until no water flowed out to obtain an organic material with a purity of 93%. Add 2g of LiTFSI aqueous solution, continue to stir for 1 hour, distill at 75°C until no water flows out; transfer to a vacuum oven, and dry at 100°C for 15 hours to obtain an organic solid electrolyte.

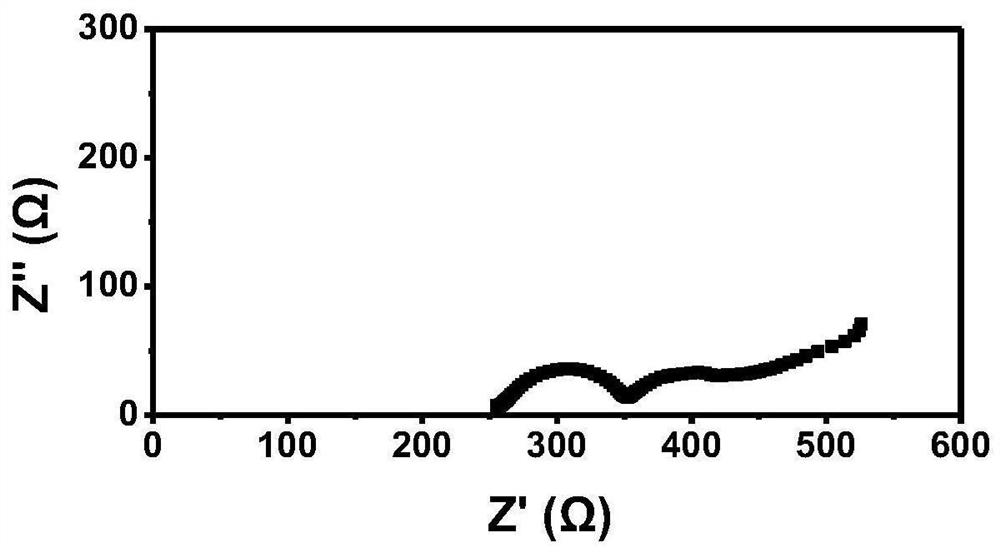

[0086] Use a PE macroporous membrane with a diameter of 16mm as the substrate, use the prepared organic matter as the electrolyte, and use a 14mm metal Li as the counter electrode to assemble a CR2032 button battery o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com