Battery module

A technology for battery modules and battery cells, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of small heat transfer area, safety risks of cooling systems, and increased equipment costs, and achieve the effect of large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

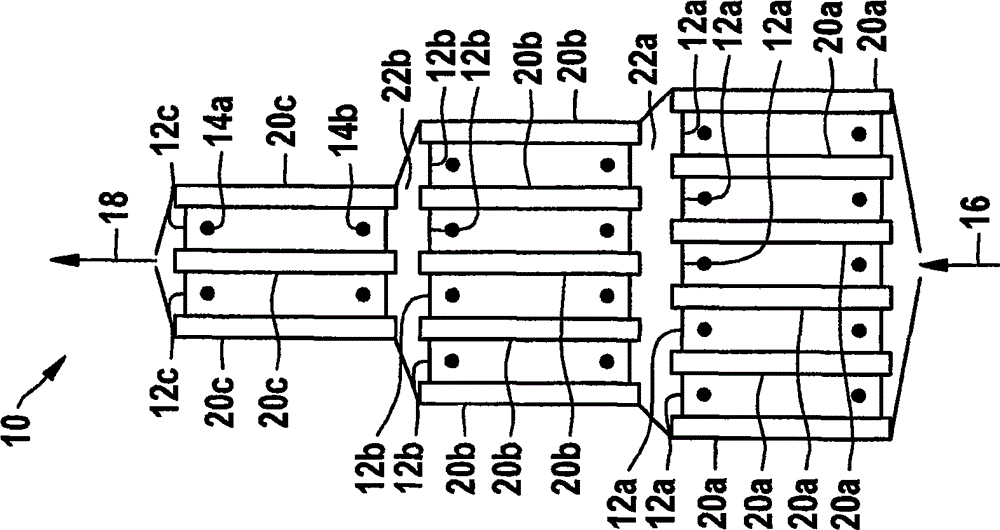

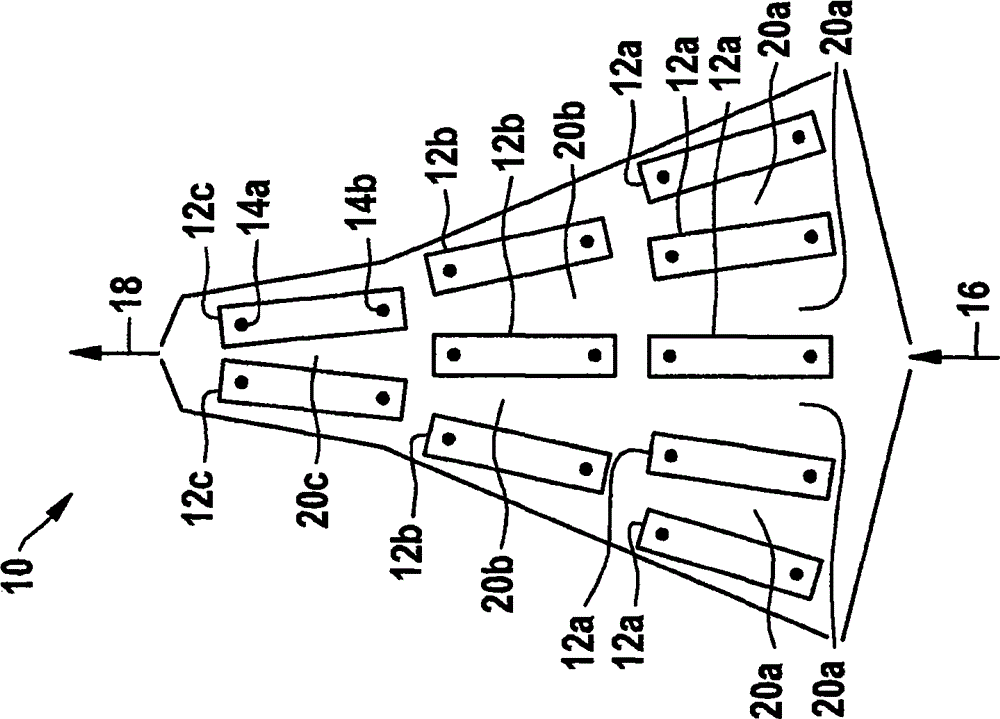

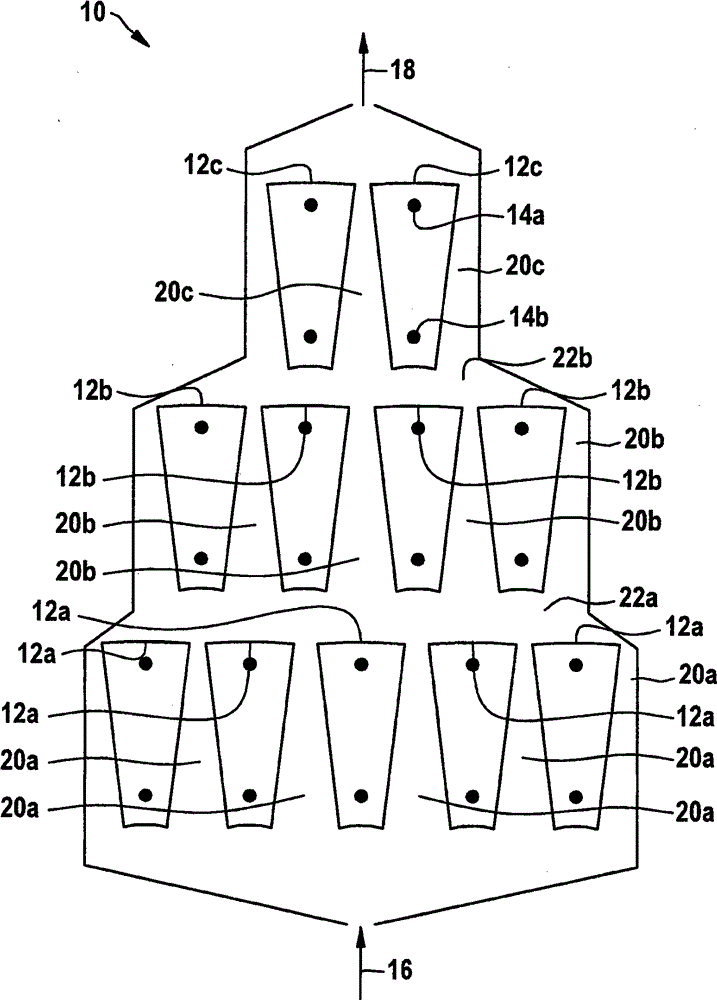

[0025] exist figure 1 A battery module 10 is depicted in , which for example comprises a plurality of battery cells 12a, 12b, 12c. The battery cells 12a, 12b, 12c each have two battery terminals 14a, 14b via which the battery cells 12a, 12b, 12c are electrically contacted. The battery cells 12 a , 12 b , 12 c are present, for example, in a cylindrical embodiment, in a prismatic embodiment or as so-called pouch-cells (batteries in pockets). In addition, the battery cells 12 a , 12 b , 12 c are connected in parallel or in series with each other in a suitable manner in the battery module 10 . Since heat is released both during charging and discharging and the corresponding battery cells 12a, 12b, 12c should be operated in a defined temperature window in order not to compromise their durability, the battery cells of the battery module 10 The individual cells 12a, 12b, 12c are temperature controlled in a suitable manner.

[0026] The concept of temperature control here includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com