Method for reducing sludge production in municipal or industrial wastewater purification stations and equipment for implementing the same

A technology for industrial wastewater and purification stations, applied in chemical instruments and methods, adjustment methods for biological treatment, biochemical equipment and methods, etc., can solve problems such as high pollution risks, and achieve the effect of reducing concentration and improving dryness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

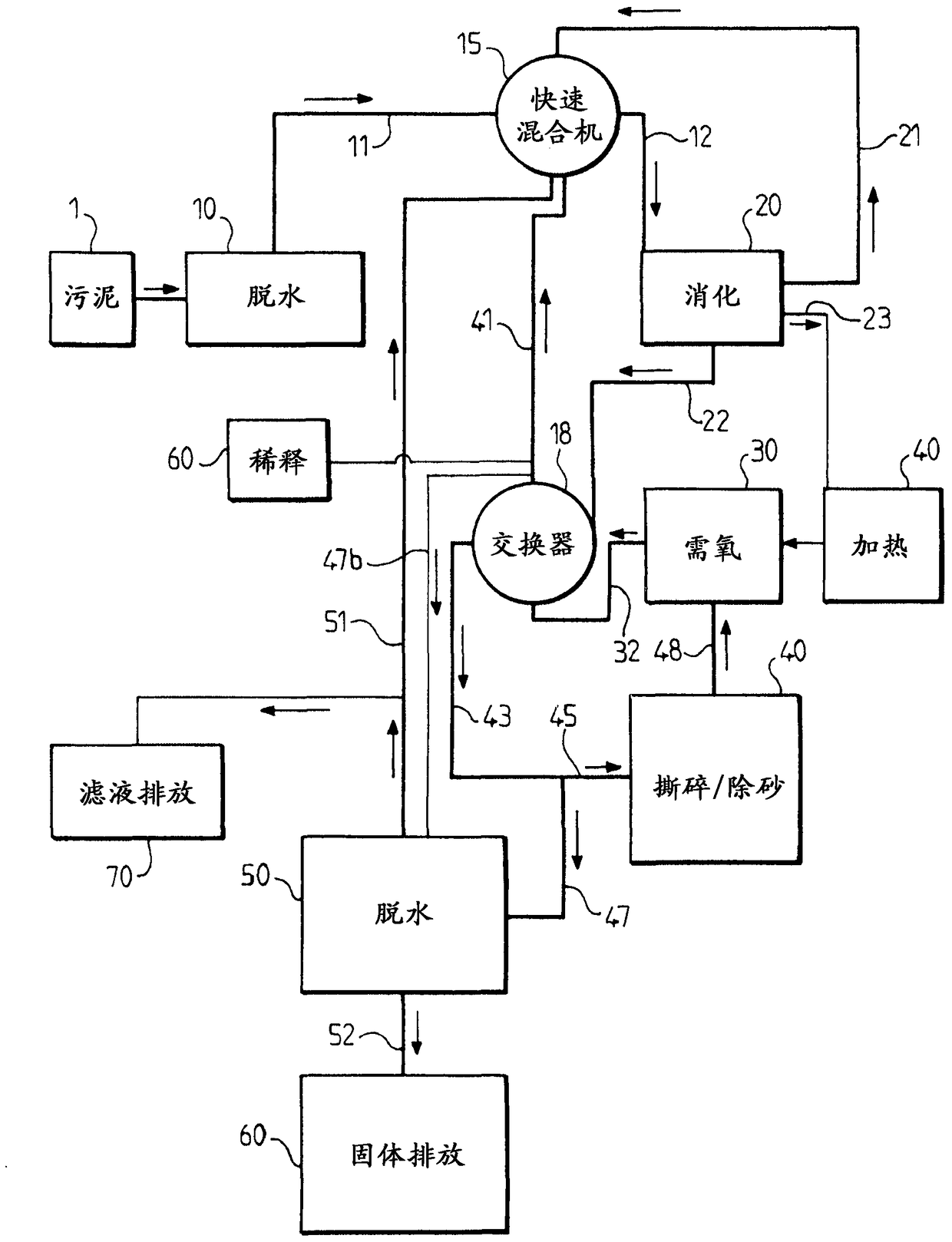

[0042] The figure shows a sludge treatment plant according to the invention comprising upstream a dewatering unit 10 of sludge 1 to be treated from a municipal or industrial water treatment line. The device 10 can be a belt filter, a centrifuge, a filter press or any other dehydration device that can significantly improve the dryness of the sludge. The higher the dryness, the greater the overall cost savings of the method. Typically, at the outlet of the dehydration unit 10, the dryness to be achieved will be 20-30% dry matter. This dewatering may involve the entire sludge stream or only a part thereof, the other part coming from piping (not shown) bypassing the device 10 .

[0043] The plant implementing the method of the invention is advantageously independent of the waste water treatment line; the sludge produced in this water treatment line is conveyed or transferred to the plant of the invention.

[0044] The outlet of the dewatering unit 10 is connected by a pipe 11 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com