An mvr continuous evaporation system

An evaporation system and evaporator technology, which is applied in the field of MVR continuous evaporation system, can solve the problems of large steam consumption, large volume, and reduced utilization rate of steam latent heat, and achieve the effect of stable feed flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

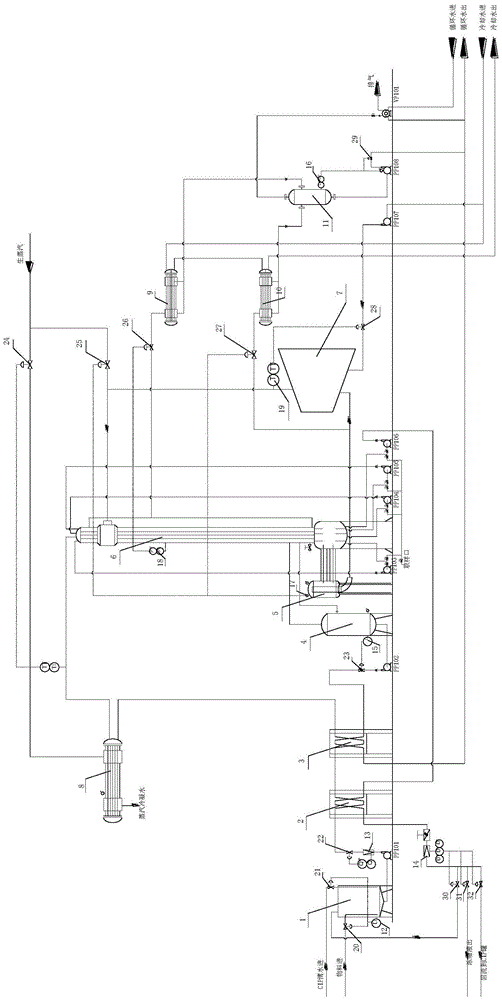

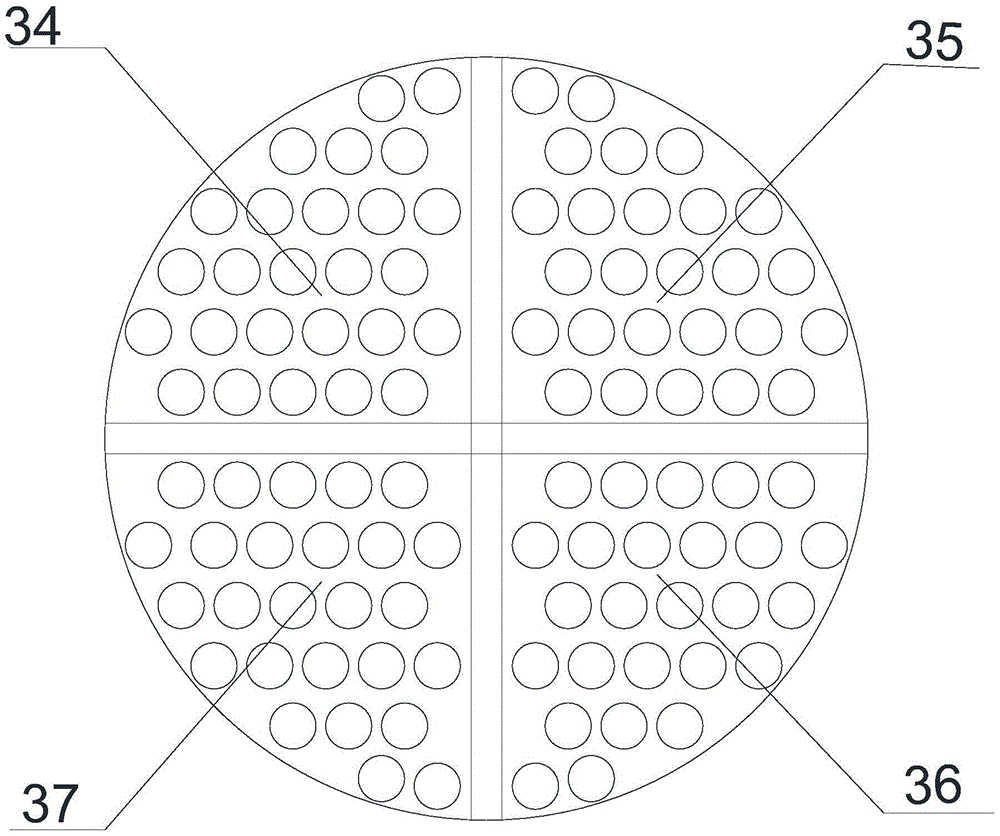

[0026]Below in conjunction with accompanying drawing and embodiment the present invention is further described, the MVR continuous evaporation system of the present invention, it comprises the raw material balance tank 1 that is connected by pipeline, control valve and relevant pump, main body evaporator 6, gas-liquid separator 5, condensation Liquid storage tank 4, steam compressor 7, vacuum system and three heat exchange devices 2, 3, 8, the bottom of the raw material balance tank 1 is connected to the inlet of the feed pump, and evaporates with the main body through the heat exchange devices 2, 3 The top of the main evaporator 6 is connected to the entrance of a section at the top. The main evaporator 6 contains four evaporation sections 34, 35, 36, 37. A gas-liquid collection chamber is arranged at the bottom of the main evaporator 6 and passes through the relay pump in sequence. Connecting to the next evaporation section, the concentrated liquid in the last evaporation sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com