Production technology for co-producing methyl isobutyl ketone and diisobutyl ketone

A technology of methyl isobutyl ketone and diisobutyl ketone, which is applied in the field of production technology of methyl isobutyl ketone, can solve problems such as increasing the energy consumption of MIBK purification tower, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

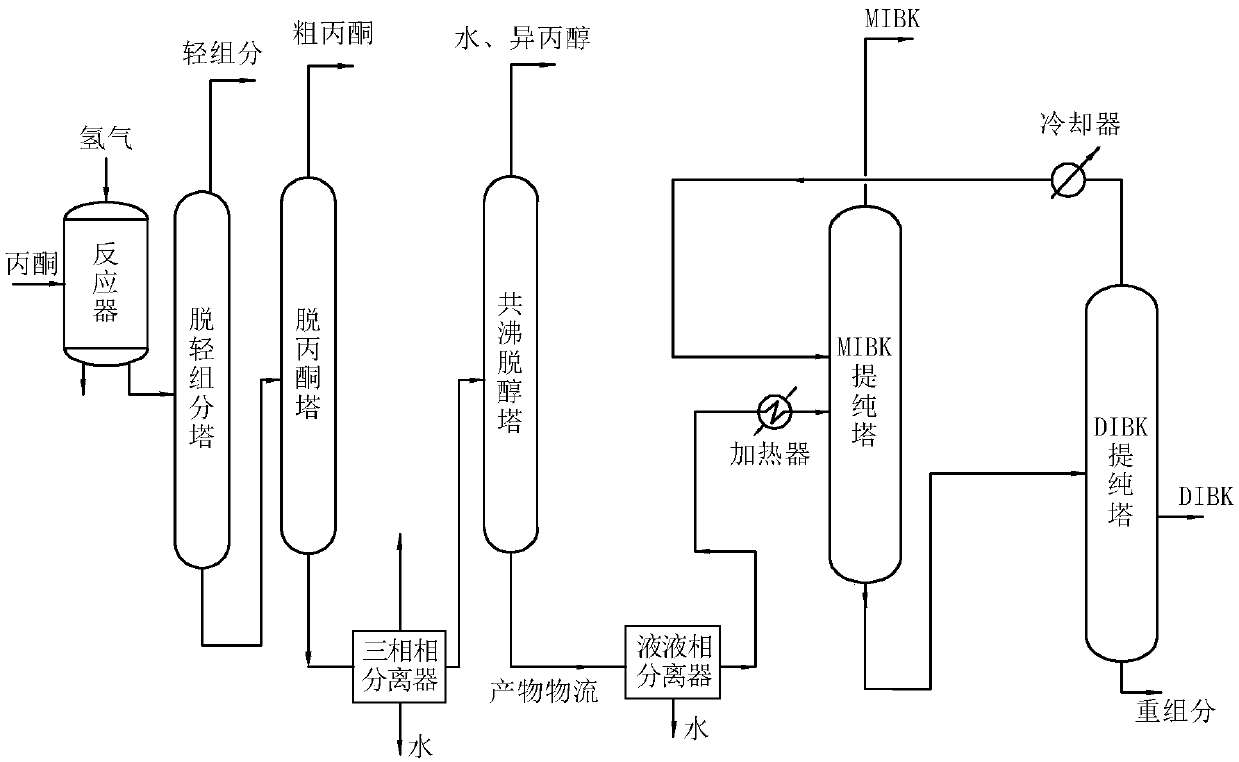

[0043] as attached figure 1 Shown, a kind of production technique of methyl isobutyl ketone coproduction diisobutyl ketone, it comprises the steps,

[0044] S1: 170kg / h of acetone and 7kg / h of hydrogen are delivered to the reactor and reacted under the action of a catalyst. The temperature in the reactor is controlled at 90-120°C, the reaction pressure is 2.72-3.13MPa, and the reactor is produced in the gas phase Transported to the hydrogen circulation process, the liquid phase produced by the reactor is a mixture flow, and the mixture flow enters the light component removal tower;

[0045] S2: The mixture stream removes the light components in the mixture stream in the light component removal tower. The operating temperature of the light component removal tower is 78-92°C, and the operating gauge pressure is 0.15-0.17MPa. The light components are extracted and sent to the acetone recycling process, and the liquid phase extracted from the bottom of the light component remova...

Embodiment 2

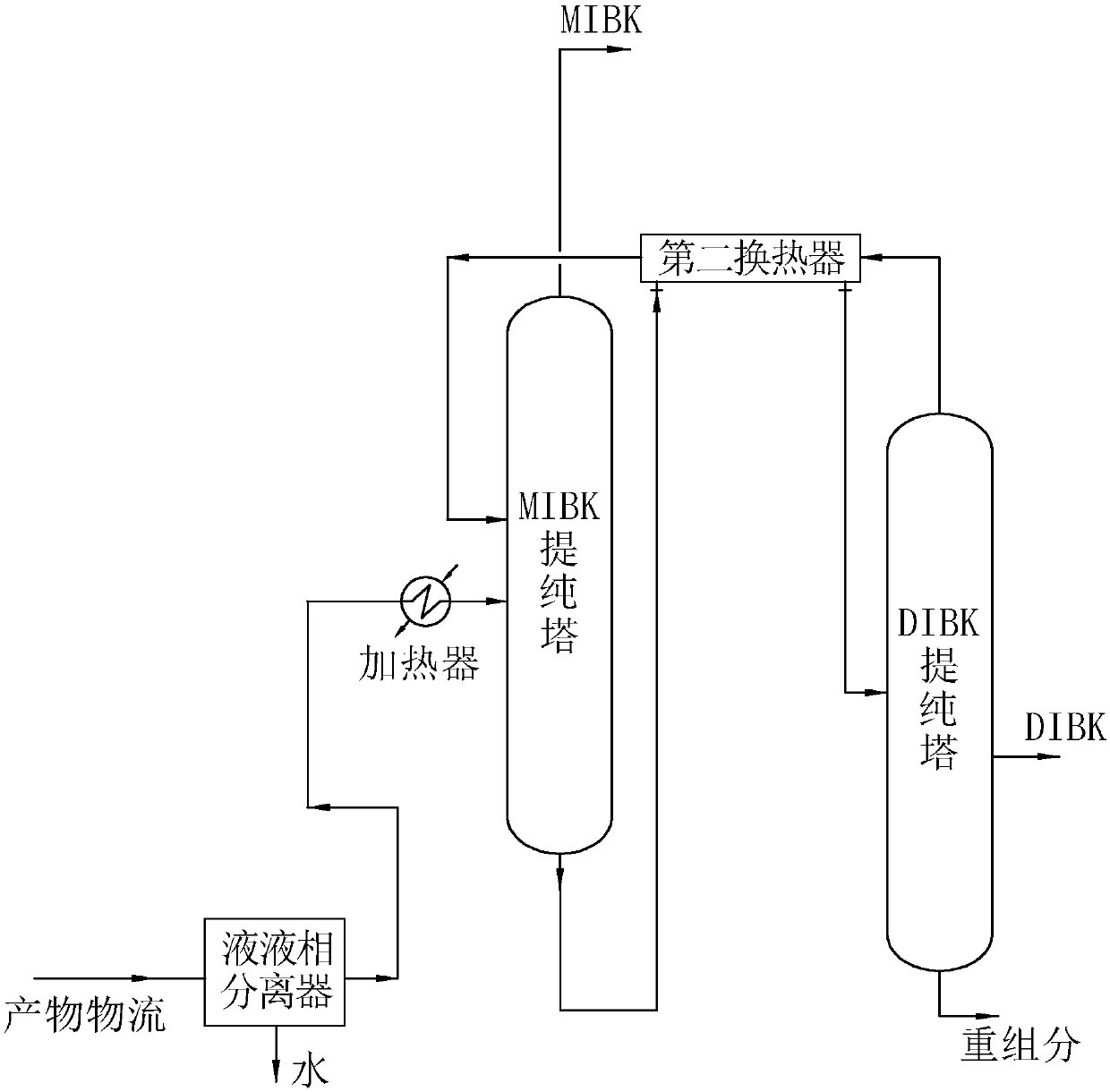

[0058] as attached figure 2 Shown, a kind of production technology of methyl isobutyl ketone co-production diisobutyl ketone is improved on the basis of embodiment one, and the stream that is rich in MIBK is extracted from the top of the DIBK purification tower and enters MIBK after heat exchange and cooling Purification tower, the cooled DIBK purification tower top extracts the stream rich in MIBK and enters the feed plate of the MIBK purification tower at a position higher than the oil phase obtained from the product stream. The liquid phase extracted from the bottom of the MIBK purification tower is the cold stream for heat exchange of the MIBK-rich stream extracted from the top of the DIBK purification tower.

[0059] Product MIBK and product DIBK were obtained according to the process test of Example 2, and the following data were obtained.

[0060]

[0061] Comparing the data obtained in Example 1 and Example 2, it can be seen that the stream that is rich in MIBK is...

Embodiment 3

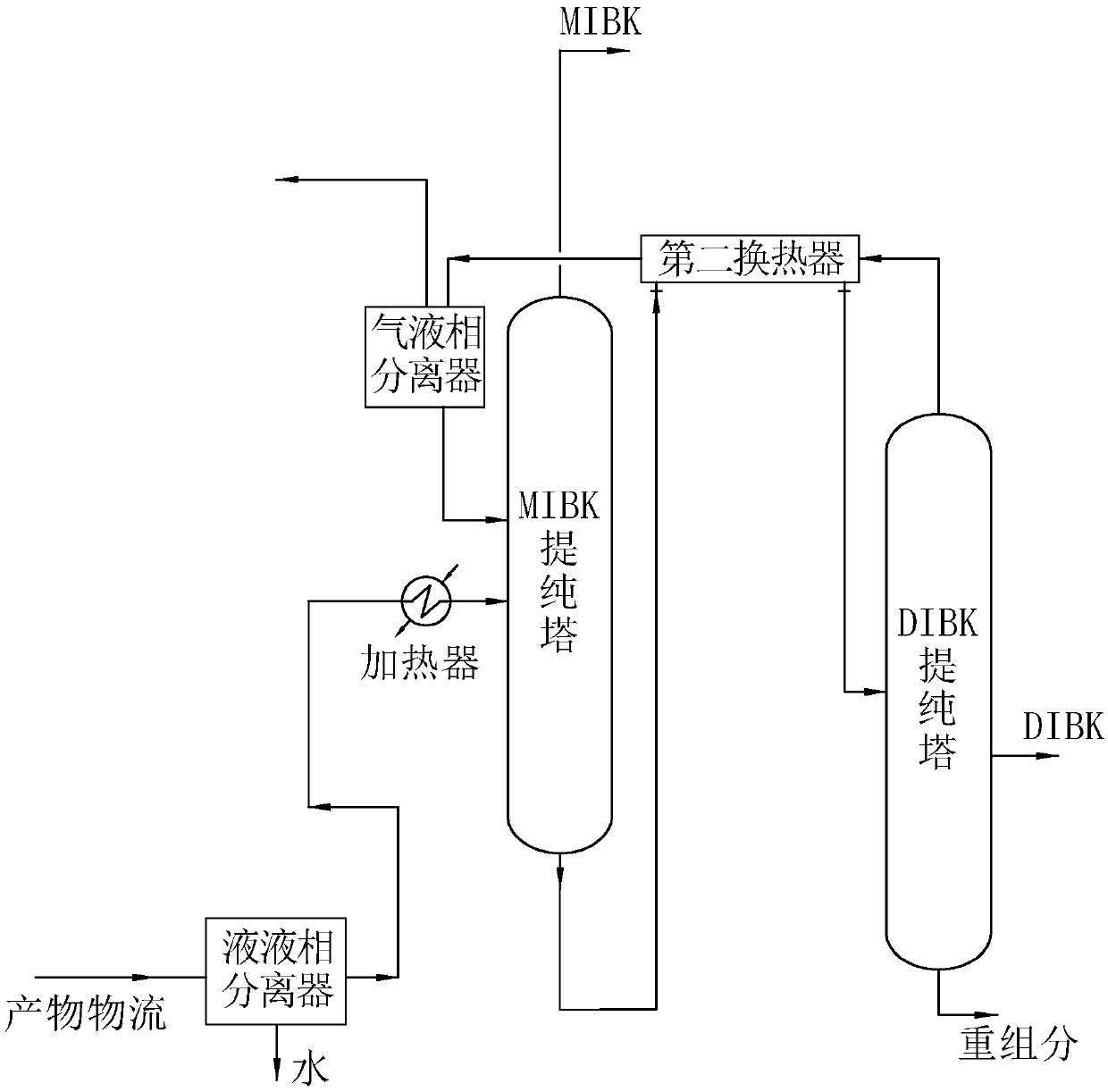

[0068] as attached image 3 Shown, a kind of production technology of methyl isobutyl ketone co-production diisobutyl ketone is improved on the basis of embodiment two, and the stream pressure after the stream cooling that is rich in MIBK is extracted from the top of the DIBK purification tower is 0.12 MPa, the temperature is 104-108°C, and the stream rich in MIBK extracted from the top of the cooled DIBK purification tower passes through the gas-liquid phase separator to separate the gas phase and then enters the MIBK purification tower.

[0069] The product MIBK and the product DIBK were obtained according to the process test of Example 3, and the following data were obtained.

[0070]

[0071] Comparing the data obtained in Example two and Example three, it can be known that the separation of the gas-liquid phase separator reduces the impurities of the light components in the stream rich in MIBK extracted from the top of the DIBK purification tower, and then improves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com