A device for cutting and stabilizing laminar cigarette packs

A technology for stabilizing sheets and cigarette packs, applied in tobacco, tobacco processing, application, etc., can solve problems such as large fluctuations, different physical properties, not perfect, etc., to meet the requirements of product quality, stable feed flow, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

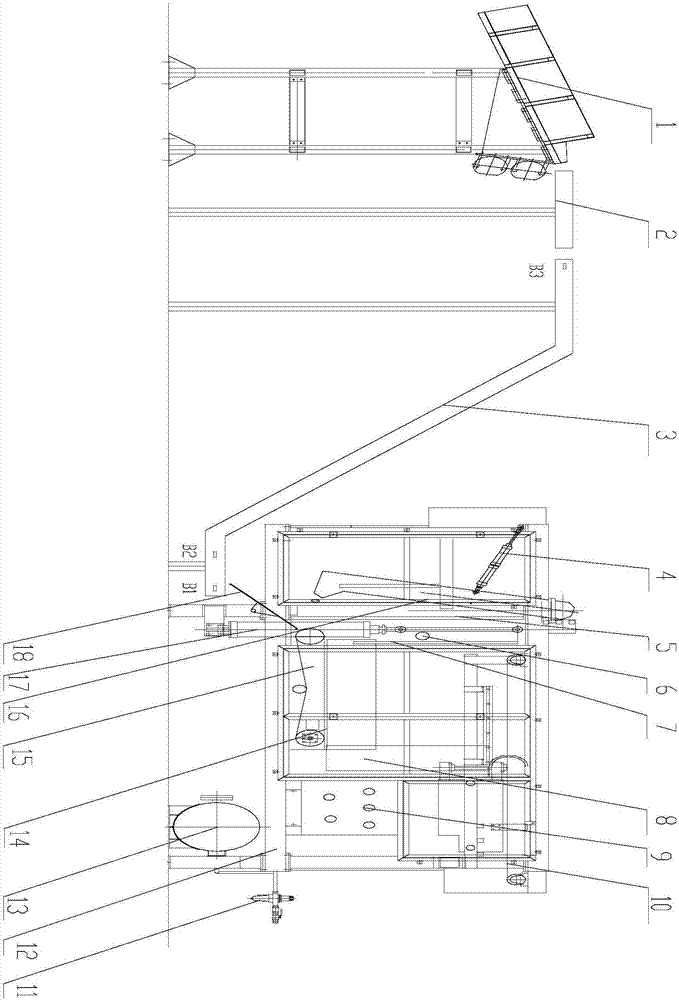

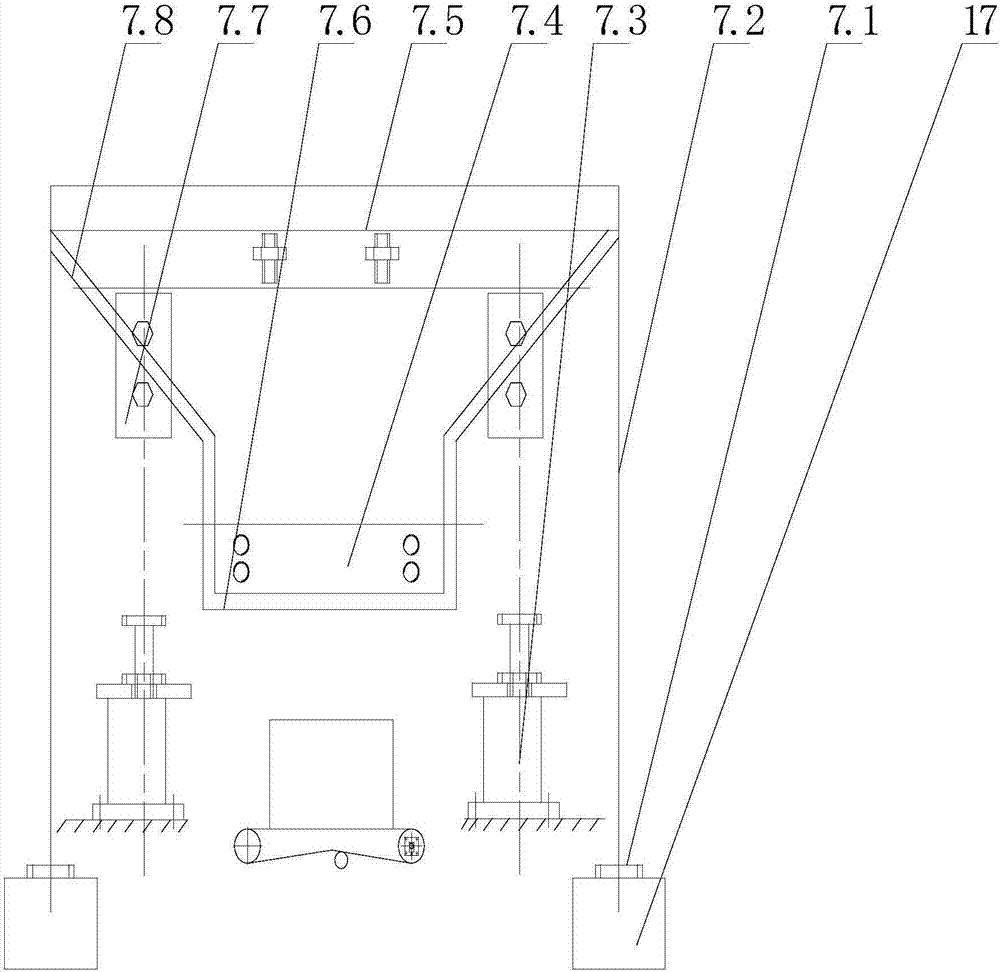

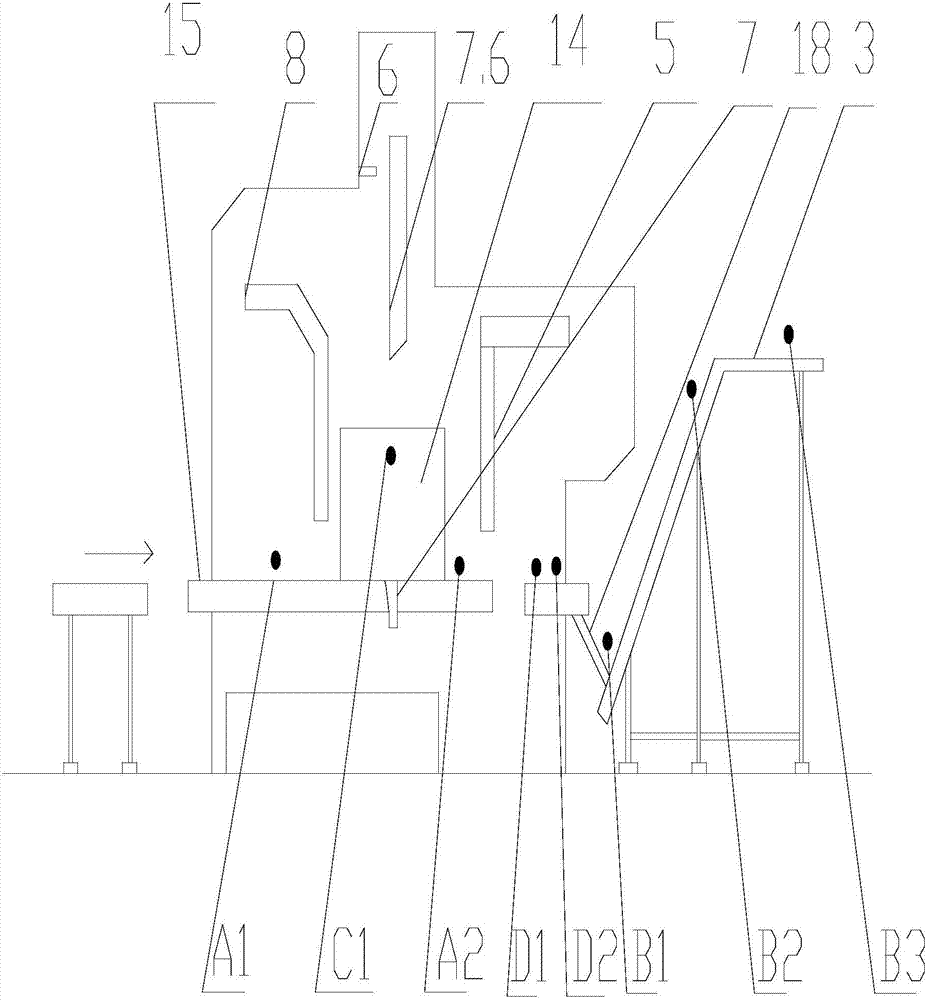

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. The working principle of the present invention is implemented by utilizing the mechanical shearing force between the cutter and the cigarette pack, and the compacted cigarette pack is cut by vertical slicing technology. attached figure 1 In the embodiment of the present invention, it is a device for cutting and stabilizing laminar cigarette packs. Its working principle is as follows: firstly, after a cigarette pack is sent to the device by a conveyor, it passes through the photoelectric cell on the device and the motor on the main shaft of the drive motor. The encoder detects the cigarette pack, and calculates the thickness of the pack and the number of cutters to be cut; then, the double cylinders on the cutter frame are driven by compressed air, and the shaft of the cylinder expands and contracts up and down, thereby dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com