Secondary slitting treatment device and method for tobacco block

A processing device and processing method technology, which is applied to the processing of tobacco, tobacco, and tobacco preparation, can solve the problems of insufficient steam addition, uneven heating, and long storage time, so as to avoid material blocking parking accidents and ensure production continuity. , The effect of convenient installation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

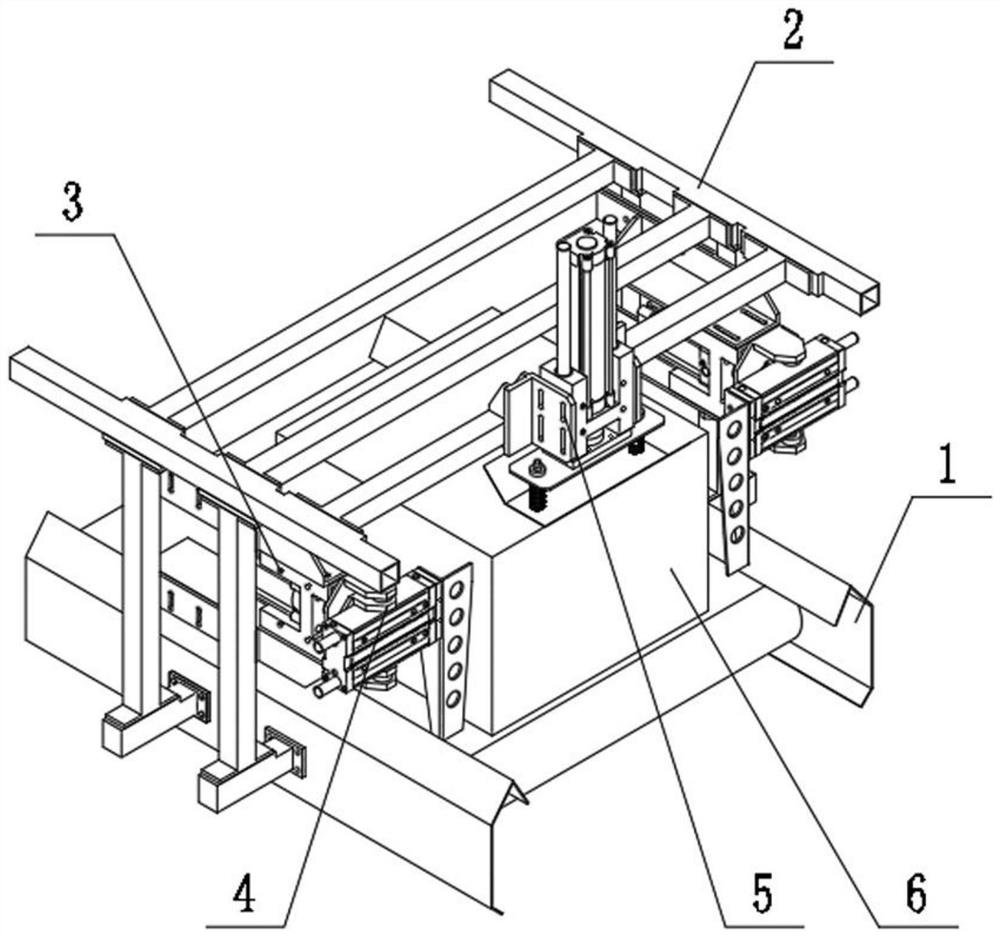

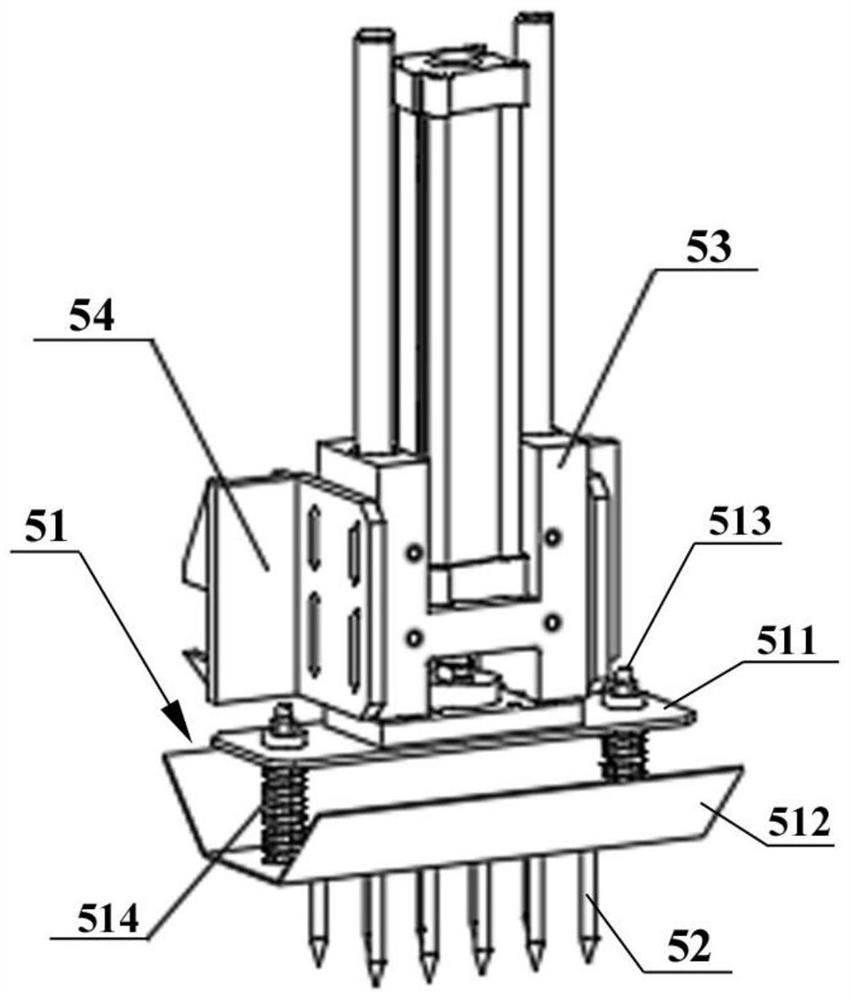

[0033] like Figure 1 to Figure 3 The device for secondary slitting and processing of cigarette blocks shown includes a frame 2, a peeling mechanism 3, a slice mechanism 4 and a separation auxiliary mechanism 5. On both sides of the exit of the front conveyor belt 1, the stripping mechanism 3 is connected to both ends of the frame 2, and can slide along the discharge direction of the cigarette block; the slicing mechanism 4 is fixed on the stripping mechanism 3, including a cutter 41. The cutter 41 can move perpendicular to the discharge direction of the cigarette block, and can rotate and swing; the separation auxiliary mechanism 5 is fixed on the middle and upper part of the frame 2, and includes an auxiliary separation member that can move up and down.

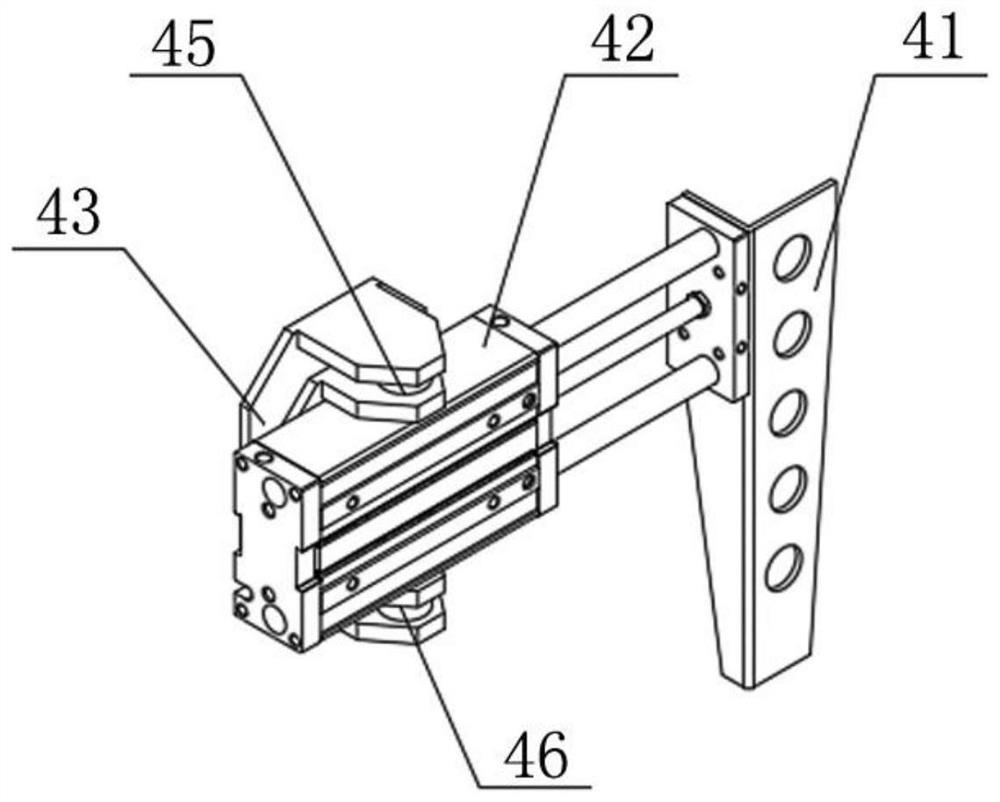

[0034] The slicing mechanism 4 described in this embodiment also includes a cutter driver 42, a rotary mechanism and a slicing mechanism fixing frame 43. The slicing mechanism includes a slewing support 44 and a rotary rubb...

Embodiment 2

[0037] A treatment method using the device described in Example 1 to carry out secondary cutting of cigarette blocks, the specific steps of the method are:

[0038] A. The vertically slit cigarette block 6 processed by the slicer is continuously advanced, and the slicing mechanism 4 enters through the two sides of the cigarette block along the pre-pressed packaging layer, and the cigarette block is disconnected;

[0039] B. After the slicing mechanism 4 is in place, the separation auxiliary mechanism 5 will move from top to bottom, and the auxiliary separation pin 15 will enter from the top of the cigarette block along the pre-pressed packaging layer, and block the part of the cigarette block at the rear of the slicing mechanism 4 at a fixed depth;

[0040] C. After the separation auxiliary mechanism 5 is in place, the peeling mechanism 3 drives the slicing mechanism 4 to push the part of the cigarette blocks in front of the slicing mechanism 4 to the discharge direction. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com