A kind of synthetic method of multistage unpowered bubbling type hydroxyethylene diphosphonic acid

A technology of hydroxyethylene diphosphonic acid and synthesis method, which is applied in the field of multi-stage unpowered bubbling hydroxyethylene diphosphonic acid synthesis, can solve the problem of unstable reaction temperature, unstable reaction temperature, hidden dangers of environmental protection, etc. problems, to achieve the effects of long contact time with materials, improved response efficiency, and reduced safety and environmental protection hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

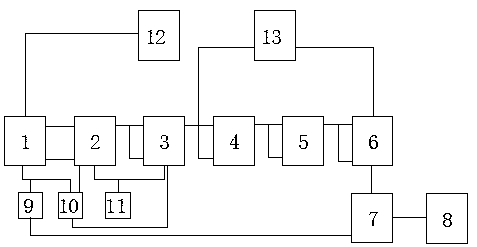

[0037] A multi-stage unpowered bubbling HEDPA synthesis method, using 6-stage tower reactors in series to synthesize, including a 1-stage reaction tower for intercepting acetyl chloride, 2-stage and 3-stage reaction towers for generating phosphorous acid and acetyl chloride. Level 4 reaction towers, 4~6 level reaction towers and hydrolysis kettles for the esterification reaction of phosphorous acid and acetyl chloride. The temperature and pressure in the 1~6 stage reaction tower are as follows: 60°C, 0.2MPa; 80°C, 0.25MPa; 90°C, 0.5Mpa; 100°C, 0.45MPa; 140°C, 0.4MPa; 130°C, 0.3MPa. The temperature setting of each reaction tower can use a built-in graphite heat exchanger to maintain the temperature parameters to meet the process requirements. At the same time, a drain valve is installed on the top of each reaction tower to avoid waste of heat energy. The reaction tower is a steel-lined polytetrafluoroethylene packed tower reactor.

[0038] Specifically, the steps are as follows:...

Embodiment 2

[0047] A multi-stage non-powered bubbling HEDPA synthesis method, using 10 stages of tower reactors in series to synthesize, including a 1-stage reaction tower for intercepting acetyl chloride, 2-stage and 3-stage reaction towers for generating phosphorous acid and acetyl chloride. Level 4 reaction towers, 4~10 level reaction towers and hydrolysis kettles for the esterification reaction of phosphorous acid and acetyl chloride. The temperature and pressure in the 1st to 10th reaction tower are as follows: 60°C, 0.2MPa; 80°C, 0.25MPa; 90°C, 0.5Mpa; 100°C, 0.46MPa; 120°C, 0.42MPa; 120°C, 0.38MPa; 140°C, 0.38MPa; 150°C, 0.30MPa; 120°C, 0.26MPa; 100°C, 0.2MPa.

[0048] Concrete steps are with reference to embodiment 1, and the liquid of 6 grades of reaction towers and gas enter 7 grades of reaction towers in the same way, and enter 8, 9 and 10 grades of reaction towers successively by 7 grades of reaction towers.

[0049] The hydrolysis kettle carries out the hydrolysis reaction. ...

Embodiment 3

[0051] A multi-stage non-powered bubbling HEDPA synthesis method, which is synthesized by 15 stages of tower reactors in series, including a first-stage reaction tower for intercepting acetyl chloride, and a second and third-stage reaction tower for generating phosphorous acid and acetyl chloride. Level 4 reaction towers, 4~10 level reaction towers and hydrolysis kettles for the esterification reaction of phosphorous acid and acetyl chloride. The temperature and pressure in the 1st to 10th reaction tower are as follows: 60°C, 0.2MPa; 80°C, 0.25MPa; 90°C, 0.5Mpa; 100°C, 0.48MPa; 120°C, 0.46MPa; 120°C, 0.44MPa; 140℃, 0.42MPa; 140℃, 0.40MPa; 150℃, 0.38MPa; 150℃, 0.36MPa; 150℃, 0.34MPa; 150℃, 0.32MPa; 120℃, 0.30MPa; 120℃, 0.28MPa; 100℃ , 0.24MPa.

[0052] The specific steps refer to Example 1. The liquid and gas in the 6-stage reaction tower enter the 7-stage reaction tower in the same way, and enter the 8-15 stage reaction tower sequentially from the 7-stage reaction tower.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com