Method for preparing charcoal/attapulgite nanocomposite from attapulgite and hogwash fat

A nano-composite material and attapulgite technology, which is applied in the field of nano-composite material preparation, can solve the problems of environmental pollution, development and utilization of urban catering swill, illegal operation, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

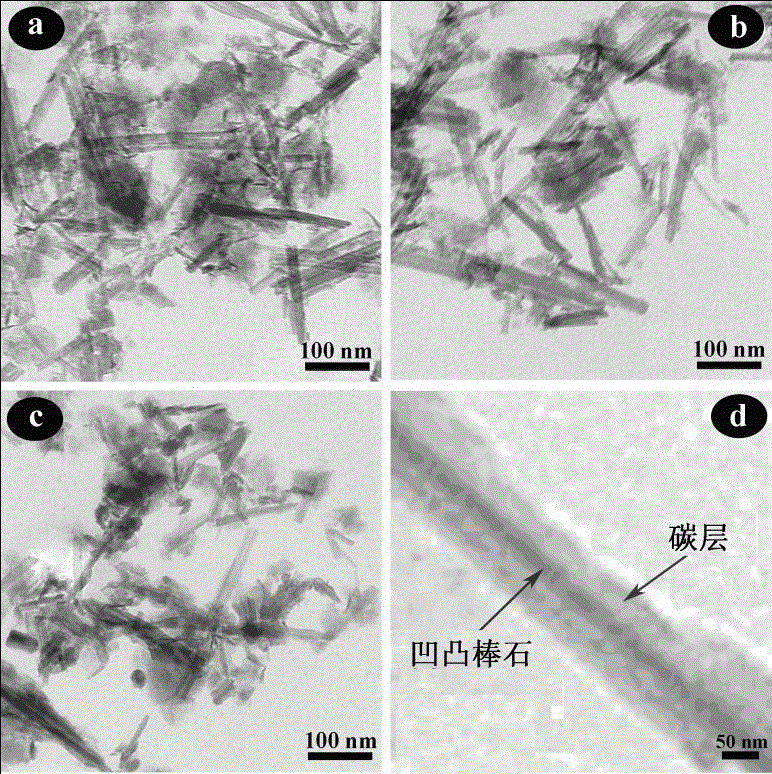

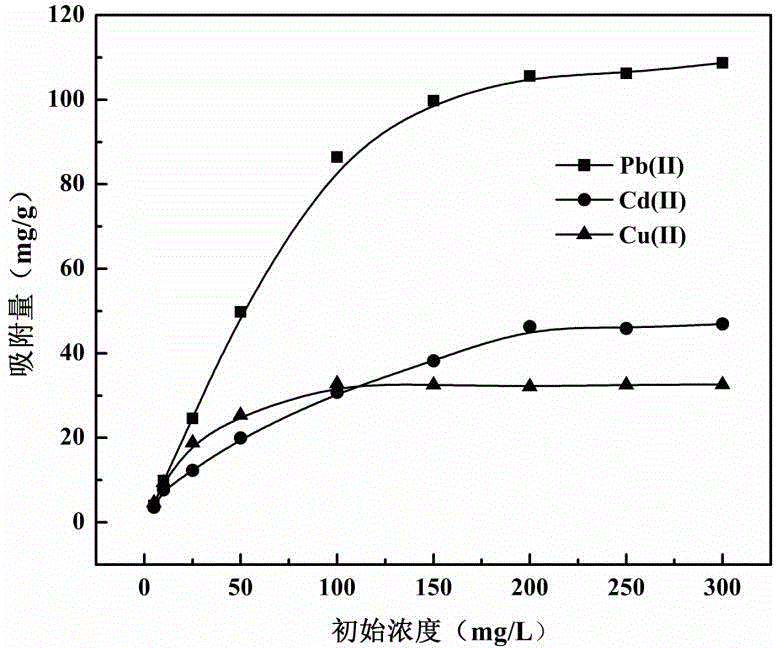

[0020] Example 1: Weigh 100kg attapulgite, directly immerse in 1000L swill oil, absorb for 4 hours, press filter, then transfer to an autoclave at 200 oC for 24 hours, wash with ethanol after cooling, dry and crush to 200 mesh to obtain loaded biochar / attapulgite Rodstone nanocomposites. The adsorption capacities of the composite for Cu(II), Cd(II) and Pb(II) were 28, 38 and 105 mg / g, respectively.

Embodiment 2

[0021] Example 2: Weigh 100kg attapulgite, directly immerse in 1000L swill oil, absorb for 12 hours, press filter, then transfer to an autoclave at 450 oC for 72 hours, wash with ethanol after cooling, dry and crush to 200 mesh to obtain loaded biochar / attapulgite Rodstone nanocomposites. The adsorption capacities of the composite for Cu(II), Cd(II) and Pb(II) were 25, 36 and 98 mg / g, respectively.

Embodiment 3

[0022] Example 3: Weigh 100kg attapulgite, directly immerse in 1000L swill oil, absorb for 24 hours, press filter, then transfer to an autoclave at 300 oC for 36 hours, wash with ethanol after cooling, dry and crush to 200 mesh to obtain loaded biochar / attapulgite Rodstone nanocomposites. The adsorption capacities of the composite for Cu(II), Cd(II) and Pb(II) were 30, 41 and 112 mg / g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com