Automatic supporting frame

An automatic and supporting frame technology, applied in the field of pipes, can solve the problems of small increase in the wall thickness of plastic pipes, waste of manpower and time, waste of raw materials, etc., to achieve the effect of fast installation, labor-saving efficiency, and resistance reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

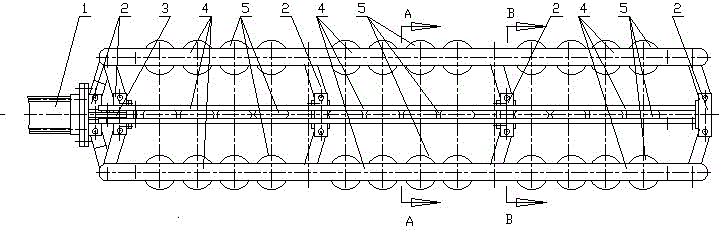

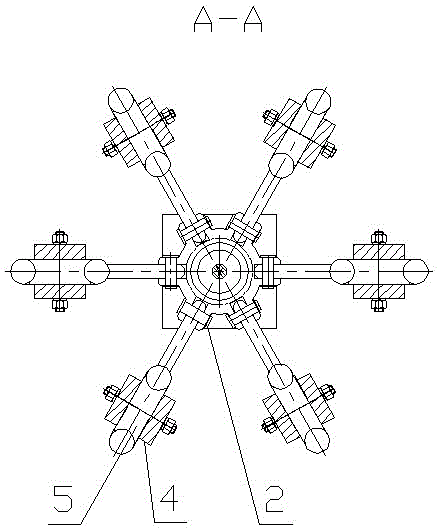

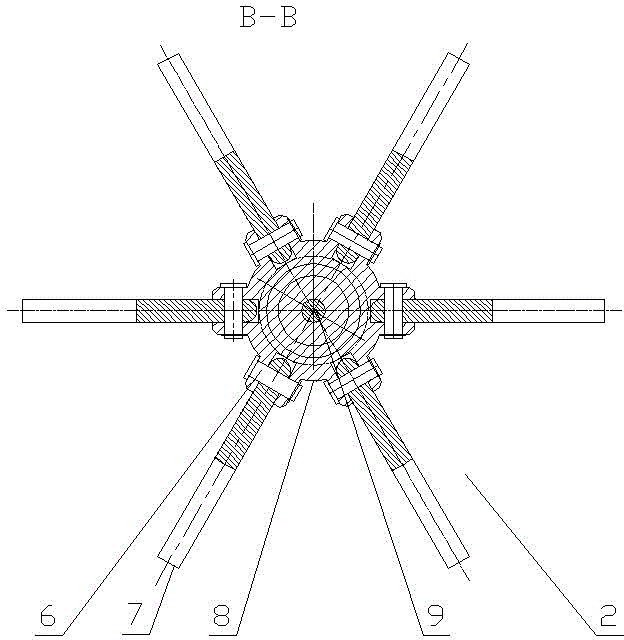

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] refer to Figure 1~4 . The automatic support frame of the present invention, which includes a support frame 2, a connecting pipe 9, a cross bar 4 and a rolling part 5. Two of the several support frames 2 are opposite to each other at the end of one side, and the rest are lined up. Adjacent support frames 2 are fixedly connected by a plurality of connecting pipes 9, and several groups, each group of two cross bars 4 are respectively placed on two of several support frames 2 uniformly distributed along the circumference of several support rods 7. The ends are hinged, and the poles 7 of the two support frames 2 facing each other on one side are hinged at one point with the cross bar 4 at the same time. Part 5. The structure of the support frame 2 is: it includes an equal support frame 8, a pole 7 and a pin shaft 6, and the equal support frame 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com