A method and device for automatically sending a detonator tube body into a bayonet

A bayonet device and tube body technology, which is applied to detonators, offensive equipment, etc., can solve the problems of automatic arrangement and simultaneous insertion of semi-finished tube bodies, and achieve the effect of unmanned operation, high efficiency and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

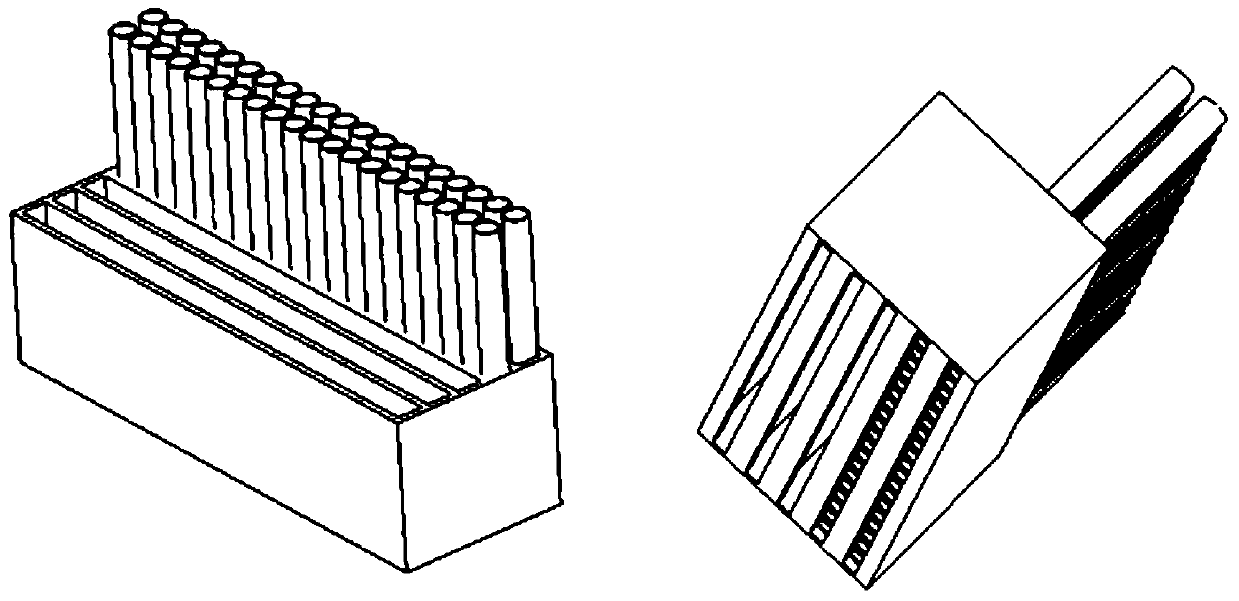

[0035] as attached figure 1 Shown is the structure of the special detonator body temporary storage box described in this device, the left side view is a three-dimensional schematic diagram of the front, and the right side is a three-dimensional schematic diagram of the bottom upside down. Temporary storage box adds dividing plate between every row of detonator bodies in conventional detonator tube body temporary storage box, facilitates the insertion of the whole line of tube body jack-up mechanism of device of the present invention, detonator body is jacked up, in the temporary detonator body of every row The central position of deposit box bottom also has the through-slot hole that width is less than detonator diameter 3mm, after making pipe body pack into temporary storage box, the bottom part of pipe body still falls on the bottom of temporary storage box and can not leak.

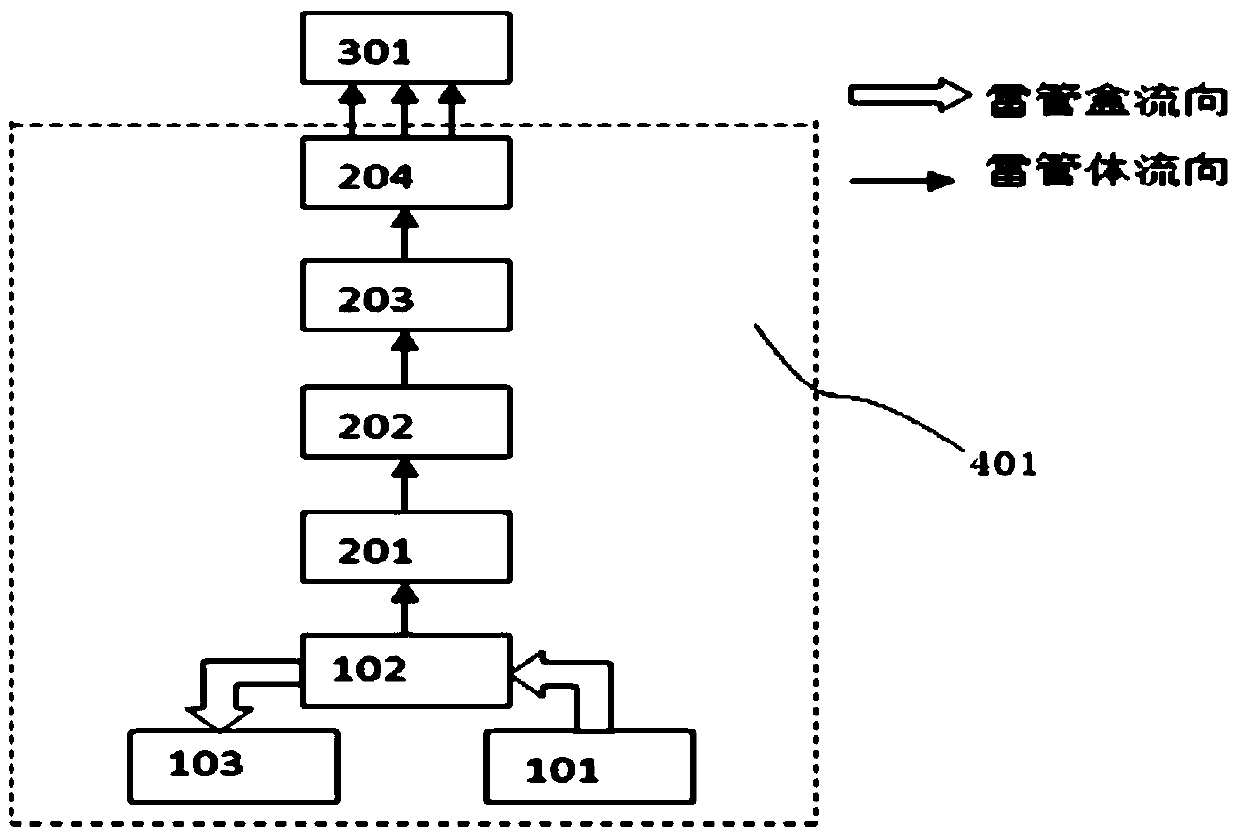

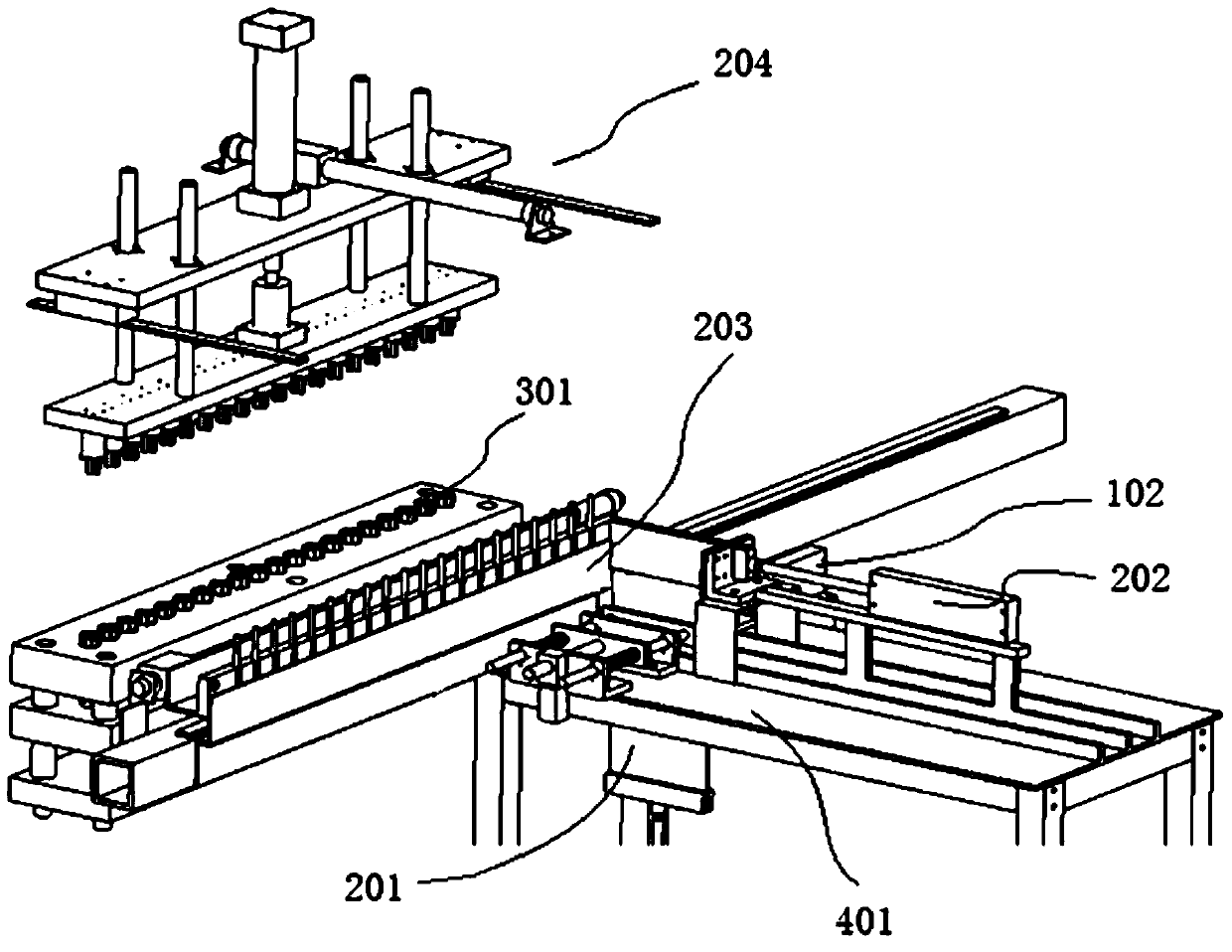

[0036] as attached figure 2 As shown, the device of the present invention is divided into 101 box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com